Crusher Operational Rock

Rock quarry crushing operations HD YouTube

2021年12月14日Rock quarry crushing operations HD. Check out this fully operational rock crushing operation making gravel. I show you all the equipment in operation

进一步探索

Simple DIY Rock Crusher FREE YouTubeDIY Homemade Rock Crusher 911Metallurgist根据热度为您推荐•反馈

Rock Crushers Mellott

2022年6月27日Rock crushers are an essential part of any mining operation. They’re used to break up large rocks into smaller pieces so they can be more easily processed

进一步探索

Rock Crusher Rental Groff Tractor EquipmentRock Crusher Rentals Rent Track Crushers The Cat Rent根据热度为您推荐•反馈

Crushing do's and don'ts : PitQuarry

2016年1月4日Place the crusher where it makes most sense, Dobler says. Also, consider if a portable setup is the way to go and what type of crusher matches your rock’s needs.

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight-hour

United States Environmental Protection Agency

operations. Rock is loaded into bins and sent through screens, sorted for size, and conveyed to one or more rock crushers until all of the raw material is reduced to the

Rock Crushing Equipment Rock Crushers Kemper

If you are a rock, sand, gravel, or mineral processing industry veteran, you know that several different types and styles of crushing equipment are used at crushing and screening plants. An individual crusher's construction

Rock Quarry Crushing Operations HD YouTube

2018年1月3日Rock Quarry Crushing Operations HD Joe Rock 7.46K subscribers Subscribe 1.5K 330K views 5 years ago YERINGTON Watch in HD, shows how large

Potential to Emit Workbook: Part 2: How to Calculate

or may be movable (e.g., concrete crusher). Operations located close to each other or tied together by other means (such as utilities or process operations) may also be part of the

Tips for designing an efficient crushing and screening

2013年4月4日The truck size and number of trucks or loaders needs to be determined to evaluate the hopper capacity. Typically, the minimum hopper live load capacity is about 1.5 times the size of the unit dumping in the

A review of modeling and control strategies for cone crushers

2021年8月15日The reader is referred to Svensson and Steer (1990) for a discussion about the physics involved in rock crushing inside a cone crusher; Bearman and Briggs, 1998, Lindqvist and Evertsson, 2006 for comprehensive insights into the effect of liner wear and feed properties on the operational characteristics of cone crushers; and Wills and Finch

Rock Crusher MachinesPulverizers Williams Crusher

A rock crusher is a device used to crush rocks into pieces of your desired size. Rock crushers are most often used for gravel, sand, and other building applications. Some of the most common types of aggregates in rock crushing are sandstone, gravel, and limestone.

United States Environmental Protection Agency General

operations. Rock is loaded into bins and sent through screens, sorted for size, and conveyed to one or more rock crushers until all of the raw material is reduced to the desired size. Each crusher machine has associated rock crusher processing 5,300,000 tons of material per year, and determined that a 150 foot setback from the

Rock Crushing Equipment Rock Crushers Kemper

Rock Crusher Types. Here at Kemper Equipment, we source our rock crushers from only the best crusher brands in the business. We also custom-design top-performing crusher systems from the industry's best

Rock Crushing Process in Mining Mineral

2015年7月18日Quaternary crushing is a rare forth stage of rock crushing, Coarse crushing includes crushing operations discharging at sizes 4- to 6-in. or coarser; intermediate crushing comprises operations taking feeds

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing.. The Experts: SandVik Mining + Metso and Quarry Academy =

ROCK CRUSHING PLANT APPLICATIONS ADVICE Oklahoma

A. Process Operations Unit CRUSHED ROCK Uncontrolled Emission Factor, lb/ton COAL Uncontrolled Emission Factor, lb/ton Crusher feed 0.007 0.007 Primary crushers 0.00070 0.2 Primary screens 0.015 0.2 Secondary crushers 0.0024 0.2 Tertiary crushers 0.0024 NA Fines crushing 0.015 NA Fines screening 0.071 NA

How to choose mining crusher and screening machine?

2023年3月8日In summary, selecting the right mining crusher and screening machine is crucial for a successful operation. Consider the type of material being mined, production capacity, particle size

Mobile crushers Metso Outotec

Families Mobile crushers are track-mounted rock crushing machines that are easily movable on and between production sites. They are widely used in aggregates production, recycling applications, and in mining operations. Mobile crushers can replace stationary crushing systems, which reduces the need for hauling and thus cuts operational costs.

Stationary VSI impact crushers, VSI Crusher

The autogenous "rock on rock" crushing technique results in several major advantages: Product gradation remains constant, contamination rates are extremely low, and it has an unbeatable product shape. CV200 VSI

Rock crusher production and operation cost analysis

Operational cost analysis of rock crushers can provide valuable insights for decision-makers in the mining and construction industries. The following are some key factors to consider: Crushers vs Cone Crushers. The two main types of rock crushers are jaw crushers and cone crushers. Jaw crushers are more common, as they tend to be

Selecting the Right Crusher for Quarry Operations Agg-Net

Sean Donaghy, national sales manager of IROCK Crushers discusses what needs to be considered when choosing a crusher. Crushing rock is an age-old idea, but the reality of the task is a far cry from that of Fred Flintstone and his good buddy Barney Rubble. Some operations do not require mobility since the projected life of the quarry will be

IJERPH Free Full-Text Platinum Mine Workers’ Exposure to Dust

2020年1月19日The South African mining industry is one of the largest producers of platinum (Pt) in the world. Workers in this industry are exposed to significant amounts of dust, and this dust consists of particles sizes that can penetrate deep inside the respiratory region. A cross-sectional study was conducted to evaluate dust exposure risk at two Pt

Real-Time Optimization of Cone Crushers Semantic Scholar

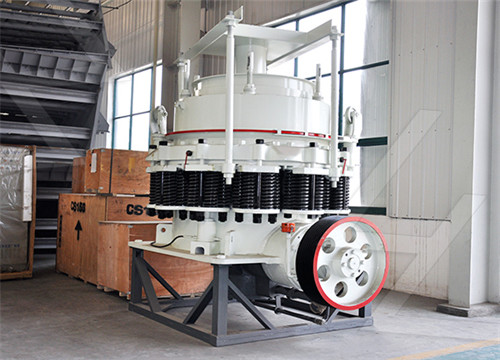

Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely used for machine protection, wear compensation and, to some extent, increasing production. These systems ordinarily focus on the crusher and not the yield of production process. In this

A review of modeling and control strategies for cone crushers

2021年8月15日The reader is referred to Svensson and Steer (1990) for a discussion about the physics involved in rock crushing inside a cone crusher; Bearman and Briggs, 1998, Lindqvist and Evertsson, 2006 for comprehensive insights into the effect of liner wear and feed properties on the operational characteristics of cone crushers; and Wills and Finch

Mobile crushers Metso Outotec

Families Mobile crushers are track-mounted rock crushing machines that are easily movable on and between production sites. They are widely used in aggregates production, recycling applications, and in mining operations. Mobile crushers can replace stationary crushing systems, which reduces the need for hauling and thus cuts operational costs.

Rock Crusher MachinesPulverizers Williams Crusher

A rock crusher is a device used to crush rocks into pieces of your desired size. Rock crushers are most often used for gravel, sand, and other building applications. Some of the most common types of aggregates in rock crushing are sandstone, gravel, and limestone.

Rock Crushing Equipment Rock Crushers Kemper

Rock Crusher Types. Here at Kemper Equipment, we source our rock crushers from only the best crusher brands in the business. We also custom-design top-performing crusher systems from the industry's best

Rock Crushing Process in Mining Mineral

2015年7月18日Quaternary crushing is a rare forth stage of rock crushing, Coarse crushing includes crushing operations discharging at sizes 4- to 6-in. or coarser; intermediate crushing comprises operations taking feeds

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing.. The Experts: SandVik Mining + Metso and Quarry Academy =

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017年3月4日The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that the

Selecting the Right Crusher for Quarry Operations

Sean Donaghy, national sales manager of IROCK Crushers discusses what needs to be considered when choosing a crusher. Crushing rock is an age-old idea, but the reality of the task is a far cry from that of Fred Flintstone

Rock crusher production and operation cost analysis

Operational cost analysis of rock crushers can provide valuable insights for decision-makers in the mining and construction industries. The following are some key factors to consider: Crushers vs Cone Crushers. The two main types of rock crushers are jaw crushers and cone crushers. Jaw crushers are more common, as they tend to be

How to choose mining crusher and screening machine?

2023年3月8日Mining operations require the use of crushers and screening machines to break down and separate raw materials. The choice of the right equipment for your mining operation can be crucial in...

Stationary VSI impact crushers, VSI Crusher

This patented design moves the material into a crushing chamber and gives the “rock on rock” (autogenous) crushing action. VSI crushers can operate within an open circuit as well as a closed, with product gradation

Real-Time Optimization of Cone Crushers Semantic Scholar

Cone crushers are used in the mineral, mining, and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely used for machine protection, wear compensation and, to some extent, increasing production. These systems ordinarily focus on the crusher and not the yield of production process. In this

TCEQ Air Quality Standard Permit for Permanent Rock and

production operations must be approved under separate authorization.) Will start-up and shutdown emissions exceed those expected during N/A N/A (1)(Q) Do you intend to authorize any facilities located at the same site as this rock crusher, by 30 TAC Chapter 106, Subchapter E, Aggregate and Pavement or 30 TAC § 106.512, Stationary Engines

Rock Crushers, Stone Crushers, Screening and Crushing

Rock Crushers. Optimize your operation and maximize your profitability with crushing and screening equipment. We offer mining jaw crushers, cone crushers, impact crushers, roll crushers and primary gyratory crushers for mining, quarrying and aggregate production. Our extensive expertise ranges from greenfield