Flow Chart Of Electrolytic Refining Of Maganese

Manganese processing Britannica

Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such as

Manganese Mining and Processing: Everything you Need

Most manganese mining occurs in open pits. Although there are processes in place to mine manganese nodules in the ocean floor, they cannot

Manganese Metal Company Refining Process

MMC’s refining process flow is designed to produce a high purity, selenium-free product while limiting the impact on the environment and protecting the health of its employees.

flow chart of electrolytic refining of maganese github

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

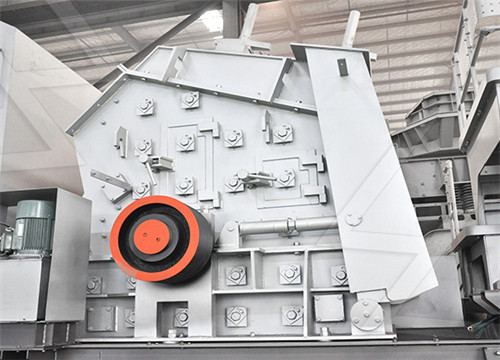

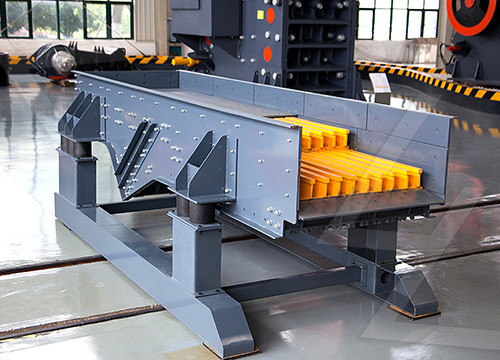

Manganese Ore Processing Mineral Processing

2016年4月27日The Manganese Gravity Recovery Circuit Flowsheet Ore Bin and Feeder Mine ore is dumped through an 8″ Grizzly into a coarse ore bin provided with a rack and pinion gate for discharging the ore to the

Electrolytic Cells Chemistry LibreTexts

2020年8月15日The direction of electron flow in electrolytic cells, however, may be reversed from the direction of spontaneous electron flow in galvanic cells, but the definition of both cathode and anode remain the

sbm/sbm flow chart for manganese ore production.md at

Contribute to changjiangsx/sbm development by creating an account on GitHub.

flow chart of electrolytic refining of maganese sub0

Gold Ore Refining Process Flow Chart,Gold Extraction Process Flow,The copper is recovered by electrolytic refining,and refining for the manganese processing.

Flow Chart Of Electrolytic Refining Of Maganese Hamela Machinery

An electrolytic composition for producing electrolytic manganese dioxide comprising an aqueous manganese sulfate solution and manganese oxides suspended therein

Magnesium processing TechniquesMethods Britannica

Electrolytic processes consist of two steps: the preparation of a feedstock containing magnesium chloride and the dissociation of this compound into magnesium metal and chlorine gas in electrolytic cells.

Electrolytic Manganese Dioxide (EMD) Mesa Minerals Limited

Overview. The first step in a conventional production flow sheet for converting manganese oxide ore to alkaline grade electrolytic manganese dioxide (EMD), which is a high purity product that possesses the ‘recipe specific’ electrical characteristics desired by batterymakers, is a high temperature pyrometallurgical roast process, wherein the

Manganese Mining and Processing for Investors, Explained

The beginning of the Manganese ore processing involves a multistage crushing workflow. From there, the production of ferromanganese, the manganese ore is mixed with iron ore and carbon and then reduced either in a blast furnace or in an electric arc furnace. The resulting ferromanganese has a Manganese content of 30% to 80%.

Electrolytic Cells Chemistry LibreTexts

2020年8月15日The general form of the reaction can be written as: (1) Reactants ⇌ Products + Electrical Energy Spontaneous Non spontaneous It is possible to construct a cell that does work on a chemical system by driving an electric current through the system. These cells are called electrolytic cells.

sbm/sbm manganese mineral process flow chart.md at main

Contribute to dihog/sbm development by creating an account on GitHub.

Manganese Ore Processing Mineral ProcessingMetallurgy

2016年4月27日The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics. The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese

Locating and Estimating Sources of Manganese US EPA

MANGANESE L &E. EPA-450/4-84-007h September 1985 3-1 End Use of Manganese and Manganese Compounds 3-11 4-1 Flow Chart of Manganese-Bearing Ferroalloys Production 4-6 Electrolytic MnO 2 Production From MnO 2 Ores and Rhodochrosite Ores 4-18 4-7 Production of KMnO 4 Roasting and Liquid-Phase Oxidation Processes 4

Manganese Ore 2023 Data 2012-2022 Historical 2024

Manganese Ore is primarily used in steel and iron production among other uses like as an additive in unleaded gasoline and as pigments for the coloring of ceramics and glass. This page refers to the Manganese Ore with 32% manganese, and 20% iron in North China, Tianjin port from South Africa.

Chapter 2. Production and Processing of Aluminum The

The starting material for electrolytic smelting of aluminum is pure, anhydrous alumi-num oxide (Al 2 O 3) called alumina. In the Western World, the Bayer 1 process, invented in the 19th century, is by far the most important process used in the production of alumi-num oxide from bauxite. The process has been refined and improved since its inception.

Flow Chart Of Electrolytic Refining Of Maganese Hamela

An electrolytic composition for producing electrolytic manganese dioxide comprising an aqueous manganese sulfate solution and manganese oxides suspended therein characterized in that the manganese oxides are used in an amount of 0.01 to 0.4 gl electrolyte and have a particle size of less than 325 mesh 0.044 mm.

Numerical simulation of magnetohydrodynamic two-phase flow

Electroslag remelting (ESR) technology has been innovatively employed to recycle the rejected electrolytic manganese metal (EMM) scrap. For a better understanding of the refining process, a transient three-dimensional comprehensive numerical model was developed based on computational fluid dynamics (CFD).

General flow sheet for producing electrolytic zinc metal and

The generalized flow-sheet for the process is given in Fig. 1. Solvent extraction and electrowinning (SX-EW) process is an integrated process with the electrolysis approach. All processing steps...

Study on Sulfur Transfer Behavior during Refining of Rejected

Metals 2019, 9, 751 2 of 20 Figure 1. Rejected electrolytic manganese metal. The mechanical performances of steel products, such as strength, ductility and toughness, are

sbm/sbm extraction and refining of manganese dioxide ore.md

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Numerical simulation of magnetohydrodynamic two-phase flow

Electroslag remelting (ESR) technology has been innovatively employed to recycle the rejected electrolytic manganese metal (EMM) scrap. For a better understanding of the refining process, a transient three-dimensional comprehensive numerical model was developed based on computational fluid dynamics (CFD).

Electrolytic Manganese Dioxide (EMD) Mesa Minerals Limited

Overview. The first step in a conventional production flow sheet for converting manganese oxide ore to alkaline grade electrolytic manganese dioxide (EMD), which is a high purity product that possesses the ‘recipe specific’ electrical characteristics desired by batterymakers, is a high temperature pyrometallurgical roast process, wherein the

Electrolytic Cells Chemistry LibreTexts

2020年8月15日The direction of electron flow in electrolytic cells, however, may be reversed from the direction of spontaneous electron flow in galvanic cells, but the definition of both cathode and anode remain the

sbm/sbm manganese mineral process flow chart.md at main

Contribute to dihog/sbm development by creating an account on GitHub.

Locating and Estimating Sources of Manganese US EPA

MANGANESE L &E. EPA-450/4-84-007h September 1985 3-1 End Use of Manganese and Manganese Compounds 3-11 4-1 Flow Chart of Manganese-Bearing Ferroalloys Production 4-6 Electrolytic MnO 2 Production From MnO 2 Ores and Rhodochrosite Ores 4-18 4-7 Production of KMnO 4 Roasting and Liquid-Phase Oxidation Processes 4

Electrolytic Refining Mineral ProcessingMetallurgy

2016年5月24日The commercial production of electrolytic metals had its origin a century ago when James Elkington, an English electroplater, invented a process for refining copper electrolytically; later, about 1890,

Manganese Ore 2023 Data 2012-2022 Historical

Manganese Ore is primarily used in steel and iron production among other uses like as an additive in unleaded gasoline and as pigments for the coloring of ceramics and glass. This page refers to the Manganese Ore

en/manganese ore processing flow chart.md at main

Contribute to jidafang2022/en development by creating an account on GitHub.

Chapter 2. Production and Processing of Aluminum The

The starting material for electrolytic smelting of aluminum is pure, anhydrous alumi-num oxide (Al 2 O 3) called alumina. In the Western World, the Bayer 1 process, invented in the 19th century, is by far the most important process used in the production of alumi-num oxide from bauxite. The process has been refined and improved since its inception.

Flow Chart Of Electrolytic Refining Of Maganese Hamela

An electrolytic composition for producing electrolytic manganese dioxide comprising an aqueous manganese sulfate solution and manganese oxides suspended therein characterized in that the manganese oxides are used in an amount of 0.01 to 0.4 gl electrolyte and have a particle size of less than 325 mesh 0.044 mm.

(PDF) Effect of Jet Flow between Electrodes on the

2018年10月17日A new copper electrolytic cell with two different inlet/outlet configurations was designed and modeled to study the effects of direct side inflows on electroplating and fluid flow field.

Study on Sulfur Transfer Behavior during Refining of Rejected

2019年7月8日A slag treatment method was proposed to recycle rejected electrolytic manganese metal. To improve the sulfur removal ratio, computational fluid dynamics and experimental studies of the sulfur

The Extraction of Copper Chemistry LibreTexts

2021年6月7日Electrolytic Refining. The purification uses an electrolyte of copper(II) sulfate solution, impure copper anodes, and strips of high purity copper for the cathodes. The diagram shows a very simplified view of a cell. At the cathode, copper(II) ions are deposited as copper. \[ Cu^{2+}(aq) + 2e^- \rightarrow Cu(s) \label{5a}\]

Manganese Ore Geoscience Australia

2019年12月31日Australia's EDR of manganese ore have increased by 50% over the last decade from 181 Mt in 2009, to 272 Mt in 2019 (Table 3). Approximately 34% of EDR is comprised of Ore Reserves with the remainder drawn from Measured and Indicated Mineral Resource estimations.