Eccentric Shafts Stone Crushing Equipment Working Principle

An eccentric solution to the primary crushing concept Quarry

2019年4月1日Consequently, the crushing gap between the crusher roll and the jaw in the crusher housing changes continuously, which means

Eccentric Shaft an overview ScienceDirect Topics

In this mill, an eccentric shaft is driven by a heavy duty enclosed motor. The shaft actuates a flywheel, which makes the upper chamber assume a rotary motion. The sample

进一步探索

What is an eccentric shaft? AnswersA Review on Design and Development of Eccentric Shaft 根据热度为您推荐•反馈

What is a Jaw Crusher? MEKA Crushing Equipment

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one

Jaw Crusher Working Principle StudiousGuy

2021年9月17日A double toggle jaw crusher consists of two shafts and two toggle plates. The first shaft is the pivoting shaft on the top of the crusher, whereas the other shaft is

Small Jaw Crushers

2016年6月1日Principle of Operation of our Small Jaw Crushers. Both types of Small Jaw Crushers are of the forced feed type. The main shaft is eccentric and on this eccentric shaft is mounted the movable jaw,

Designing Eccentric Shaft Of Crushers Crusher Mills, Cone

Jaw Crusher-Forged heavy-duty eccentric shaft-The good Cavity Design -Prompt Delivery -Best After Sale Service. Type: Jaw Crusher. Hewlett packard Cone Crusher

Working Principle of Crushers Mineral Processing

2016年2月17日Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position “1.” Note that the length of

VIBRATING ECCENTRIC SHAFT Crusher Mills, Cone Crusher, Jaw

Operating PrincipleThe vibrator is made of two fixed eccentric shafts whose gears are jogged. ADJUSTABLE PHASE TWO SHAFT VIBRATOR Rex Chainbelt, Inc. A

Eccentric Shafts Stone Crusher Working Principle Sangli-Miraj

Eccentric Shafts Stone Crusher Working Principle Sangli-Miraj Kupwad. Impact crusher is a kind of commonly used stone crushing equipment which can process

What is the eccentric throw? — SRP

The eccentric throw is one of the most important parameters in defining the job that your cone crusher does. The mantle in a cone crusher spins in conical pendulum motion. That means it doesn’t stay in the center

Crushers an overview ScienceDirect Topics

In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw. A double toggle crusher has, basically, two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of the crusher, while the other is an

An eccentric solution to the primary crushing

2019年4月1日Consequently, the crushing gap between the crusher roll and the jaw in the crusher housing changes continuously, which means the feed material is crushed by compressive forces as it falls by gravity, until

Eccentric Shaft an overview ScienceDirect Topics

In this mill, an eccentric shaft is driven by a heavy duty enclosed motor. The shaft actuates a flywheel, which makes the upper chamber assume a rotary motion. The sample container, C, is clamped to the chamber wall and contains a

Gyratory Crushers Mineral ProcessingMetallurgy

2016年2月17日In the Gyratory crusher, the eccentric is located directly below the crushing head. This design permits the use of a short, rigid mainshaft a mainshaft that will withstand the strain of severe service.

Jaw Crusher Working Principle StudiousGuy

The first shaft is the pivoting shaft on the top of the crusher, whereas the other shaft is the eccentric shaft that is used to drive both the toggle plates. Advantages of a Jaw Crusher 1. Jaw crushers are comparatively inexpensive. 2. Both the structure and working of a jaw crusher are quite simple. 3.

VIBRATING ECCENTRIC SHAFT Crusher Mills, Cone Crusher, Jaw

Operating PrincipleThe vibrator is made of two fixed eccentric shafts whose gears are jogged. ADJUSTABLE PHASE TWO SHAFT VIBRATOR Rex Chainbelt, Inc. A vibrating mechanism for a two-shaft screen. Eccentric shafts are supported by bearings in the side plates of the screen frame or in mounts above or below

Brief Introduction Of Jaw Crusher And It’s Working

Jaw crusher is an early crusher equipment which has characteristic of high crushing ratio, simple structure, reliable operation, easy maintenance, economical operating cost etc. Jaw crusher is widely used in mining,

Eccentric Shafts Stone Crusher Working Principle Sangli-Miraj

Eccentric Shafts Stone Crusher Working Principle Sangli-Miraj Kupwad. Impact crusher is a kind of commonly used stone crushing equipment which can process various coarse medium and fine materials like granite limestone concrete etc with less than 500mm side length and 350MPa compressive strength Ball Mill Working Principle

eccentric shafts stone crusher working principle

vibrating feeder working principle Be Happy Forever Ling Vibratory feeder ; Jaw Crusher,Cone Crusher,Stone Crusher ; Working Principle of Vibrating Feeder: There are two eccentric shafts rotating at high speed at the same time from opposite directions, thus the strong centrifugal ; The Working Principle and Introduce of Vibrating.

What is a Jaw Crusher? MEKA Crushing Equipment

In single-toggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to which it is attached. The pitman is supported by a toggle plate at the bottom of the moveable jaw.

Cone Crusher Operation Principle

Cone Crusher Price, Cone Crusher Cost, Primary Cone Crusher . 1.hydraulic cone crusher uses a unique operating principle named “eccentric bushing circum fixed shaft”. it enhances working principle of hydraulic cone crusher.

Gyratory Crusher Explained saVRee

Eccentric motion is achieved by the lower eccentric bushing and drive arrangement on the bottom of the main shaft. The input pinion drive countershaft is supported by pinion bearings and powered by an electric motor. An external gearbox or belt drive arrangement reduces the motor speed to approximately 100-200 RPM at the crusher.

Eccentric Shafts Stone Crushing Equipment Working Principle

Stone Crushing Equipment. 2018. 2. 6. The broken Basalt Artificial Stone Crushing Equipment work process, most of the material for the irregular shape, is the point of contact with the material caused by extrusion broken, plus gravity continuous friction to a fixed jaw and a movable jaw plate, friction force and shear stress, the movable jaw plate in the

What is the eccentric throw? — SRP

The eccentric throw is one of the most important parameters in defining the job that your cone crusher does. The mantle in a cone crusher spins in conical pendulum motion. That means it doesn’t stay in the center

Crushers an overview ScienceDirect Topics

In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action of the moving jaw. A double toggle crusher has, basically, two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of the crusher, while the other is an

An eccentric solution to the primary crushing

2019年4月1日Consequently, the crushing gap between the crusher roll and the jaw in the crusher housing changes continuously, which means the feed material is crushed by compressive forces as it falls by gravity, until

Gyratory Crusher Explained saVRee

Eccentric motion is achieved by the lower eccentric bushing and drive arrangement on the bottom of the main shaft. The input pinion drive countershaft is supported by pinion bearings and powered by an electric motor. An external gearbox or belt drive arrangement reduces the motor speed to approximately 100-200 RPM at the crusher.

Gyratory Crushers Mineral ProcessingMetallurgy

2016年2月17日In the Gyratory crusher, the eccentric is located directly below the crushing head. This design permits the use of a short, rigid mainshaft a mainshaft that will withstand the strain of severe service. TOP SHELL constructed of cast steel. Inside finished for concaves. Note tapered fit for spider.

Designing Eccentric Shaft Of Crushers Crusher Mills, Cone Crusher

Jaw Crusher-Forged heavy-duty eccentric shaft-The good Cavity Design -Prompt Delivery -Best After Sale Service. Type: Jaw Crusher. Hewlett packard Cone Crusher switches into computer . The friction disc design and rotation of eccentric shaft bushing around fix cone plus much more reasonable “labyrinth seal . The crusher can offer

Cone Crusher Operation Principle

Cone Crusher Price, Cone Crusher Cost, Primary Cone Crusher . 1.hydraulic cone crusher uses a unique operating principle named “eccentric bushing circum fixed shaft”. it enhances working principle of hydraulic cone crusher.

Brief Introduction Of Jaw Crusher And It’s Working Principle

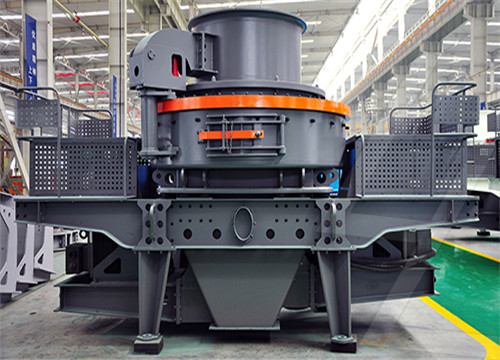

Jaw crusher is an early crusher equipment which has characteristic of high crushing ratio, simple structure, reliable operation, easy maintenance, economical operating cost etc. Jaw crusher is widely used in mining, smelting, building material, highway, railway, conservancy, chemical industry and many other sectors with compression strength less than 350MPA.

Eccentric Shafts Stone Crusher Working Principle Sangli-Miraj

Eccentric Shafts Stone Crusher Working Principle Sangli-Miraj Kupwad. Impact crusher is a kind of commonly used stone crushing equipment which can process various coarse medium and fine materials like granite limestone concrete etc with less than 500mm side length and 350MPa compressive strength Ball Mill Working Principle

eccentric shafts stone crusher working principle

vibrating feeder working principle Be Happy Forever Ling Vibratory feeder ; Jaw Crusher,Cone Crusher,Stone Crusher ; Working Principle of Vibrating Feeder: There are two eccentric shafts rotating at high speed at the same time from opposite directions, thus the strong centrifugal ; The Working Principle and Introduce of Vibrating.

Jaw Crusher for Primary Crushing Fote Machinery

1 Working principle of single toggle jaw crushers is that swing jaw plate that’s moving up/ down as the flywheel rotated by the motor. 2 The eccentric is located at the top of the swinging jaw, which makes the jaw can perform two motions at the same time. 3 Large CSS adjustments are made to the jaw crusher by modifying the length of the toggle.

Cone Crusher Explained saVRee

The pinion on the countershaft meshes with the eccentric gear drive, or crown gear. Crown Gear. The inner surface of the eccentric bushing is machined off-centre from the centre-axis of the crusher. As the eccentric bushing rotates, the lower shaft oscillates in an elliptical orbit around the centreline of the crusher. This action causes the

Introduction to the working principle of sizer crusher

2.Principle of cone crusher There are many kinds of cone crushers. These cone crushers are based on the principle of lamination crushing. We take HPT multi-cylinder hydraulic cone crusher as an example, when it works, the motor drives the equipment transmission shaft through the pulley and the triangle belt, the transmission shaft drives the eccentric

Jaw Crusher Eastman Rock Crusher

Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.