High Energy Attritor Type Horizontal Rotary Ball Mil

Conventional Ball Mill vs. Attritors Union Process

The graph below compares various mills during the high energy ball milling process. Select a link to learn more about these Attritor-style stirred ball mills: Dry Grinding

进一步探索

Attritor Ball Mill Superfine Grinding Stirred Ball Mill EnergProcess Mills, Attritors, Media Mills, Paint Mills Detroit Pro根据热度为您推荐•反馈

Types of mills for high-energy milling: A-ball mill, B

根据热度为您推荐•反馈

Attritor Ball Mill Superfine Grinding Stirred Ball Mill

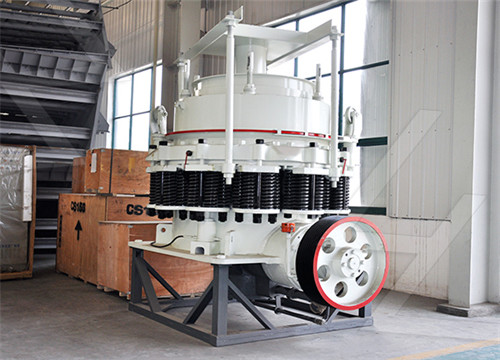

Attritor Ball Mill Volume of Barrel: 50-1000L Rotate Speed: 88-130r/min Motor power: 3-30kw Applications: It is suitable for metal, nonmetal ore, paint, ink, pigment, stone coating, ceramic glaze, magnetic material,

Horizontal attritor type Mill (Zoz). Download Scientific

Xudong Lu. The high temperature oxidation behavior of alloy GH4720Li has been studied using static weight increment method. Scanning electron microscopy (SEM), energy

Attritor Ball Mill WetDry Grinding Stirred Ball Mill

The attritor ball mill is mainly composed of a grinding cylinder, agitator, lining plate, grinding media, driving system, frame, pneumatic diaphragm pump, and lubrication system. Cylinder Cover: it can be used with a

Rotary Ball Mill for High Uniformity Grinding of

Rotary ball mill is composed of feeding part, discharging part, turning part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts. The hollow shaft of the rotary ball mill is made of

High Energy Ball Mill Cost Crusher Mills

High Energy Attritor type Horizontal Rotary Ball Mill . High Energy Ball Mill ManufacturersHigh Energy . Lead Oxide Ball Mill: 1.reduce energy cost by 30%

high energy attritor type horizontal rotary ball mill

high energy ball mill simoloyer cm08. Jun 20, 2020 high energy attritor type horizontal rotary ball mill. ball mill, hammer mill, roller mill machine, manufacturer of high

Types of mills for high-energy milling: A-ball mill, B

Types of mills for high-energy milling: A-ball mill, B-planetary mill, C-vibration mill, D-attritor (stirring ball mill), E-pin mill, F-rolling mill. 4k Modified from ref. 4d....

High energy ball milling process for nanomaterial

It is a ball milling process where a powder mixture placed in the ball mill is subjected to high-energy collision from the balls. This process was developed by Benjamin and his coworkers at the International Nickel

Attritor Stirred Ball Mill Sepor, Inc

The Attritors are designed for media ranging from 1/8” to 3/8” and run at RPM’s of 100 to 500. Adjustable agitator shaft height to accommodate different size grinding media. Bottom discharge grid with valve for easy sampling and discharge. Tank slides forward and tips @ 90 degrees for media discharge and fast cleaning.

sbm/sbm high energy ball mill attritor planetary.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Title : Attritors and their types (Unit 4) Engineering

velocity), which enables us to see how the Attritor fits into the family of mills. For example, ball mills use large media, normally 1/2”or larger, and run at a low (10-50) rpm. The other mills, such as sand, bead, and horizontal, use smaller media from 0.3mm to 2mm, but run at a very high rpm (roughly 800-1200).

Types Of Horizontal Ball Milling Crusher Mills, Cone Crusher,

Find the Right and the Top High Energy Attritor type Horizontal Rotary Ball Mill for your coal handling plant! liming, a mining machines manufacturer in china focus on Horizontal mill_Ball Mill Horizontal ball mill is a relatively old conventional type ball mill, the stone describes the use of horizontal ball mill products, technical

High Energy Ball Mill Cost Crusher Mills

types of ball mill 1. high efficiency and energy- saving 2. widely application 3. good quality and low price ball mill machinery 1:high efficiency 2: Planetary Ball Mill design pm 400 Manufacturer,high energy south africa ball mill prices; Continuous ball mill;

High Energy Attritor Type Horizontal Rotary Ball Mill

Liberia Attritor Ball Mill Diameter. a ball mill is a grinding machine used to grind, blend, and sometimes for mixing of materials for use in geology, ceramics, metallurgy, electronics, pharmacy, construction material, and light industry, etc. ball mills are classified as attritor, planetary ball mill, high energy ball mill, horizontal ball mill, or shaker mill.

高能研磨式卧式旋转球磨机 电子游艺棋牌平台,正规电子游戏娱乐,

high energy attritor type horizontal rotary ball mil ball milling process: Topics by WorldWideScience Surfactant assisted high energy ball milling results to the samples& 39; the composition Fe-19.5Cr-5Ni processed in

High-Energy Ball Milling an overview ScienceDirect Topics

High-energy ball milling, also called mechanical attrition, can be used to reduce the grain size of materials from many micrometers to 2–20nm (see Mechanical Alloying ). This is a result of the cold-working process creating large-angle grain boundaries.

New Developments in Attritors PCI Magazine

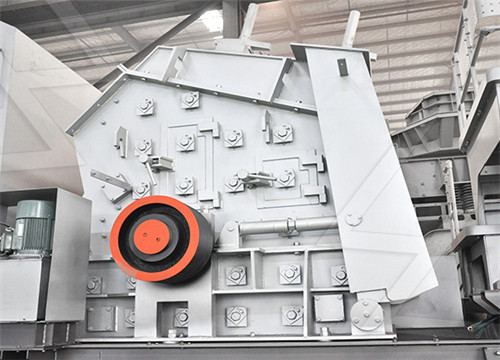

2001年3月26日The attritor, or stirred ball mill, is a grinding mill containing internally agitated media. There are quite a few types of attritors; they can be categorized as dry grind, wet grind, regular speed (to 400

high energy attritor type horizontal rotary ball mill

high energy ball mill simoloyer cm08. Jun 20, 2020 high energy attritor type horizontal rotary ball mill. ball mill, hammer mill, roller mill machine, manufacturer of high energy ball mill across international ball mill contect in india, CM08 and CM20) in . ; hi speed ball mill celebrationcakes. High-energy ball mill . get price

LABORATORY GRINDING MILLS Union Process

product contamination, change media size and type, and get precise energy consumption information, all on the same machine. Results are repeatable from one test grind to another for maximum credibility. Finally, the Attritor is ideal for formulating, quality control, and scale-up studies. On Cover: S1 Attritor equipped with Touch-Screen

Wet Batch Production Mills Union Process

The Attritor is often referred to generically as an “internally agitated high energy media (ball) mill.” Batch Attritors work ten times faster than ball mills, and are advantageous because they offer simple operation, rugged construction, and a compact design. To learn more, visit our Education Center. Request a Quote Lab Trial Form

(PDF) DESIGN OF A BALL MILL TYPE ATTRITOR FOR

2005年11月6日vertical and horizontal attritor ball mills. The vertical Attritor type ball mill is basically made up of the following part s: motor, prope ller, container, refrigeration chamber, and su pport base.

Wet Batch Production Mills Union Process

The Attritor is often referred to generically as an “internally agitated high energy media (ball) mill.” Batch Attritors work ten times faster than ball mills, and are advantageous because they offer simple operation,

LABORATORY GRINDING MILLS Union Process

The Multi-Tank HD-01 Lab Attritor System is the ultimate set-up for quality control and test grinding requirements. • All tanks (expandable from 2 to 6) are controlled by ONE power source. • A timing belt assures that all connected Attritor shafts run at the same speed for the same period of time.

High energy ball milling process for nanomaterial

It is a ball milling process where a powder mixture placed in the ball mill is subjected to high-energy collision from the balls. This process was developed by Benjamin and his coworkers at the International Nickel

Ball Mills, Attritor, Crusher Mills, Cone Crusher, Jaw Crushers

Benchtop High Energy Planetary Ball Mill, Model is multiple, Benchtop High Energy Planetary High Energy Attritor type Horizontal Rotary Ball Mill Coal Find the Right and the Top High Energy Attritor type Horizontal Rotary Ball Mill for your coal handling plant! liming, a mining machines manufacturer in china focus on Sitemap |

Attritor Stirred Ball Mill Sepor, Inc

The Attritors are designed for media ranging from 1/8” to 3/8” and run at RPM’s of 100 to 500. Adjustable agitator shaft height to accommodate different size grinding media. Bottom discharge grid with valve for easy sampling and discharge. Tank slides forward and tips @ 90 degrees for media discharge and fast cleaning.

sbm/sbm high energy ball mill attritor planetary.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Title : Attritors and their types (Unit 4) Engineering

velocity), which enables us to see how the Attritor fits into the family of mills. For example, ball mills use large media, normally 1/2”or larger, and run at a low (10-50) rpm. The other mills, such as sand, bead, and horizontal, use smaller media from 0.3mm to 2mm, but run at a very high rpm (roughly 800-1200).

Types Of Horizontal Ball Milling Crusher Mills, Cone Crusher,

High Energy Attritor type Horizontal Rotary Ball Mill Coal Find the Right and the Top High Energy Attritor type Horizontal Rotary Ball Mill for your coal handling plant! liming, a mining machines manufacturer in china focus on Horizontal mill_Ball Mill

High Energy Attritor Type Horizontal Rotary Ball Mill

Liberia Attritor Ball Mill Diameter. a ball mill is a grinding machine used to grind, blend, and sometimes for mixing of materials for use in geology, ceramics, metallurgy, electronics, pharmacy, construction material, and light industry, etc. ball mills are classified as attritor, planetary ball mill, high energy ball mill, horizontal ball mill, or shaker mill.

高能研磨式卧式旋转球磨机 电子游艺棋牌平台,正规电子游戏娱乐,

high energy attritor type horizontal rotary ball mil ball milling process: Topics by WorldWideScience Surfactant assisted high energy ball milling results to the samples& 39; the composition Fe-19.5Cr-5Ni processed in

High Energy Milling / Mechanical Alloying / Reactive Milling

Since about eight years, Zoz specializes in the technology of Mechanical Alloying (MA). This is performed by a high kinetic milling process that, due to extremely high and / or often needed active surface of the powder-product, shall mostly be done under complete inert-gas condition, sometimes under vacuum. The equipment that is developed, produced and

Working Principle of Attritor Mill ballmillssupplier

An attritor mill, also known as a stirred ball mill, is a type of milling equipment used for grinding materials into fine particles. It is characterized by its unique working principle, which involves a high-speed rotating shaft with agitator elements. The agitator elements consist of impellers or discs that are mounted on the shaft and rotate

Stirred Mill an overview ScienceDirect Topics

The classification on a scale of increasing mill energy is: horizontal ball mill, attritor, planetary ball mill and vibrating ball mill. For example, a process that takes only a few minutes in the SPEX mill can take hours in an attritor and a few days in a commercial tumbler ball mill. High speed attritor [24] 0.5–3: 320–1700