Grinding Raw Meal Price List Ball Mill

Raw Meal Grinding Ball Mill for Cement grinding Plant of

Quality Raw Meal Grinding Ball Mill for Cement grinding Plant find quality Grinding Equipment, Mine MillGrinding Equipment from Zhengzhou Huanqiu Heavy Industries

Raw material mill Great Wall

2022年9月20日 Raw material ball mill, also called raw meal ball mill, is important grinding equipment in cement production process After being

Raw Meal Ball Mill gwmcn

2023年2月15日 Raw Meal Ball Mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials

Modern Ball Mill Prices For Spectacular Efficiency

Ceramic Liner Ball Mill Machine Price Ball Grinding Mill Small Laboratory Ball Mill From Henan Manufacturer. $730.00-$803.00 / set. 1 set (Min Order) CN The Nile Machinery

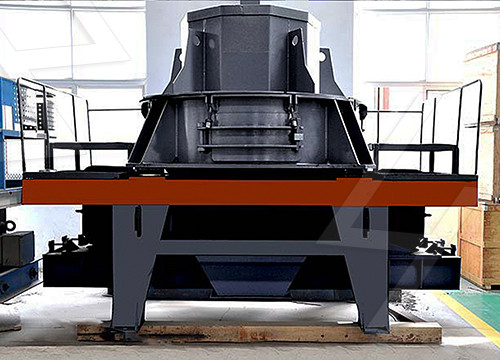

RAW VERTICAL MILL

2021年7月6日 Overview. Raw Material Grinding (Vertical Mill) is mainly used for grinding raw meal, clinker, which is used in cement grinding station, cement production line.

How to choose between ball mill and vertical roller mill?

2022年6月24日 The ball mill has the unique advantage of “the particle shape is approximately spherical, which is conducive to the calcination of raw meal and the

ball mill Industrial Solutions

Ball Mill. The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a

Raw Mill Raw Mill In Cement Plant AGICO Cement Raw

Cement vertical mill, also called roller mill, is another raw mill commonly used in cement plants. Compared with the cement ball mill, it has a great difference in structure, grinding

Grinding Mills Price, 2023 Grinding Mills Price

FOB Price: US$ 6800 / set. Min. Order: 1 set. Zhengzhou Hengxing Engineering Technology Co., Ltd. View larger videoimage. Contact Now. Video. 5-200t/D Complete Electric

Raw Material Drying-Grinding Cement Plant Optimization

Raw Material Drying-Grinding. Drying of moisture in raw materials is required for effective grinding and subsequent handling of raw meal. This is achieved normally by ducting part

Fives Grinding in ball mills with FCB B-mill

The FCB B-mill is particularly well adapted to grinding products at high fineness, as well as very abrasive products and solid fuels. Featuring customized design, steady operation, and pioneering shoe-bearing

Laboratory mill, Laboratory grinding mill All industrial

Comex has developed a new dry grinding system employing a ball mill working with an air classifier with 0.5- or 0.8-mm screen to produce meal with particle size distribution as follows: >500 μm, 0–10%; >210 but 500 with changes to the cost of raw materials and exchange rates. HOW TO SOURCE PRODUCTS. Exhibit with us. FAQ. Brand list;

Vertical Raw Mill for Cement Raw Meal Grinding in Ball

Vertical Raw Mill. Feeding size: 35-110mm. Capacity: 12-350t/h. Motor power: 255-3600kW. Applications: It can be used for grinding limestone, gypsum, siliceous, coal and other materials. It is mainly used in cement raw materials grinding section of cement factory, and also be used in concrete and mineral fields. Email: info@ballmillssupplier.

Cement Raw Mill in Cement Plant for Cement Raw Meal

Raw mill is also called cement raw mill, similar to cement ball mill, it is an important cement milling equipment used in the cement production process. Raw mill is mainly used for grinding cement raw meal in the cement factory production process. It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind

Optimization of a fully air-swept dry grinding cement raw

2015年4月1日 Production capacity of a fully air-swept industrial scale two-compartment KHD Humboldt Wedag® cement ball mill was optimized with the aid of simulatio

Fritsch GmbH Powder mills All the products on

High performance in minimum space The Planetary Mono Mill PULVERISETTE 6 classic line is a high-performance Planetary Ball Mill with a single grinding bowl mount and practical, Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. HOW TO SOURCE PRODUCTS. Exhibit with us. FAQ.

How to choose proper grinding media for your ball mill

2021年2月24日 1. Steel Balls. Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 120mm according to different grinding requirements. In a cement ball mill, generally, φ50–100mm steel balls are used in the coarse grinding chamber, φ20–50mm steel balls are used in the fine grinding chamber.

Cement Mill Cement Grinding Machine AGICO Cement

The cement grinding mill in a cement plant mainly includes cement vertical mill, cement ball mill, ultra fine grinding mill, cement roller press, etc. They are suitable for both wet process and dry process. AGICO offers EPC cement projects and different kinds of equipment needed for cement plant, such as a series of cement mills: cement ball

Ball Mill Working Principle And Main Parts GitHub Pages

2015年7月14日 Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the

sbmchina/sbm prizes of grinding meals in zimbabwe.md

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Raw Meal Ball Mill gwmcn

2022年10月19日 Raw Meal Ball Mill is mainly used in grinding raw materials and final products in cement plant. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries. Suitable enterprise type: cement plant. Output:21~210t/h. Effective volume:29.5~185 m3.

Laboratory mill, Laboratory grinding mill All industrial

Comex has developed a new dry grinding system employing a ball mill working with an air classifier with 0.5- or 0.8-mm screen to produce meal with particle size distribution as follows: >500 μm, 0–10%; >210 but 500 with changes to the cost of raw materials and exchange rates. HOW TO SOURCE PRODUCTS. Exhibit with us. FAQ. Brand list;

Modern Ball Mill Prices For Spectacular Efficiency

Ceramic Liner Ball Mill Machine Price Ball Grinding Mill Small Laboratory Ball Mill From Henan Manufacturer. $730.00-$803.00 / set. 1 set (Min Order) CN The Nile Machinery Co., Ltd. 6YRS. 5.0 China price raw material cement ball mill / Limestone Coal Clinker Grinding Ball Grinding Mill Machine / set. 1 set (Min Order) CN Shanghai Yingyong

Fritsch GmbH Powder mills All the products on

High performance in minimum space The Planetary Mono Mill PULVERISETTE 6 classic line is a high-performance Planetary Ball Mill with a single grinding bowl mount and practical, Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates. HOW TO SOURCE PRODUCTS. Exhibit with us. FAQ.

Ball Mill GrinderBall Grinding Mill For Sale Different

Ball mill is one of the most variable and effective grinding machines which is mainly applied for further grinding the crushed materials. Compared with other grinding mills, the variety of grinding modes, available grinding tool materials, and flexible production capacity make ball mill grinders the perfect match for a vast range of applications, such as cement industry,

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density

Grinding Mills Common Types Mineral

2016年11月7日 In Fig. 1.3 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging

Cement Mill Cement Grinding Machine AGICO Cement

The cement grinding mill in a cement plant mainly includes cement vertical mill, cement ball mill, ultra fine grinding mill, cement roller press, etc. They are suitable for both wet process and dry process. AGICO offers EPC cement projects and different kinds of equipment needed for cement plant, such as a series of cement mills: cement ball

sbmchina/sbm prizes of grinding meals in zimbabwe.md

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Coal Mill in Cement Plant Vertical Roller MillAir-Swept

It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are air-swept ball mills and vertical roller mills. At present, most cement plants use coal as the main fuel in the clinker production process. The standard coal consumed by the new dry process for producing 1 ton of cement