Bisha Mining Process Plant Crusher Sag Mill

sbm/sbm bisha dressing process plant grinding sag

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise

github

how does the sag mills operate in the mining plant Rethinking the value of mill relining Mining Magazine Difference Between Sag Mill vs Ball Mill CEMTEC: CEMTEC

Sag Mill Operation Mobile Crushing Plant Price

Bisha Mining Process Plant Grinding Sag Mill. CrushersMills Mining Data Online. Crusher Mill Type Crusher Mill Model Job Category Job Title Contact Name Area

bisha mining process plant grinding sag mill gulin machinery

Bisha Mining Process Plant Grinding Sag Mill Me Mining. Mining process plant grinding sag mill gearless mill drives abbs gmd is the most powerful mill drive system in the market to

Bisha Mining Process Plant Grinding Sag Mill

2020年11月2日 Dec 27 2014 The Bisha mine was discovered in January 2003 and a feasibility study was completed in October 2006 After the Social and Environmental

bisha mining process plant grinding sag mill

2019年11月10日 bisha mining process plant grinding sag mill. AG/SAG mills are normally used to grind run-off-mine ore or primary crusher product. Wet grinding in an

bisha mining process plant grinding sag mill

UNUSED Process Plant including SAG Mill, (2) Ball Mills, Jaw Crusher, Cone Crusher, Double Deck Screen, CIL Agitators, Dual Drive Thickeners, Filters, and More! (2)

bisha efficient process plant ball mill sag mill

May 18, 2021bisha mining process plant grinding sag mill. home; bisha mining process plant grinding sag mill; bisha mining process plant grinding sag mill. Dec 27 2014 The Bisha

Dynamic modeling and simulation of a SAG mill-pebble

2018年10月1日 SAG mill model. The dynamic model of an AG/SAG mill includes several interlinked sub-process modules, and these modules can be updated individually. As shown in Fig. 1, the mill is divided into n sections, where m is the section number and q is the transported material. All sections have the same length, and each section contains a

Dynamic modeling and simulation of a SAG mill-pebble

2018年10月1日 The dynamic model of an AG/SAG mill includes several interlinked sub-process modules, and these modules can be updated individually. As shown in Fig. 1, the mill is divided into n sections, where m is the section number and q is the transported material. All sections have the same length, and each section contains a dataset of

SAG Mill Grinding Circuit Design Mineral

2016年6月6日 Single stage AG/SAG milling. AG/SAG mills as a primary grinding stage in a circuit with or without additional stages of comminution. Inclusion of pebble-crushing circuits in the AG/SAG circuit. Circuits

sbm/sbm bisha dressing process plant grinding sag

Contribute to changjiangsx/sbm development by creating an account on GitHub.

What’s the Difference Between Ball Mill, Rod Mill and SAG

2020年3月20日 Ball mill: When the particle size of the product is less than 0.5mm, the grinding effect of the ball mill is greater than that of a rod mill of the same specification. SAG mill: The SAG mill has a wide range of feeding particle sizes and can process larger minerals, but at the same time, its output particle size is relatively larger.

Autogenous GrindingSemi Autogenous

2017年7月20日 Figure 3 shows a typical semi-autogenous (SAG) circuit with feed coming directly from a primary crusher, and the semi-autogenous mill product going to the separation process. Many similar

Difference Between Sag Mill vs Ball Mill

1. SAG mill is the primary tool for grinding. SAG mill is used before the other mills. Ball mill is a secondary, and it is used after the SAG mill. 2. SAG mill breaks the raw material into pieces for the further grinding. Ball mill is

github

how does the sag mills operate in the mining plant Rethinking the value of mill relining Mining Magazine Difference Between Sag Mill vs Ball Mill CEMTEC: CEMTEC sophisticated tech

bisha mining process plant grinding sag mill

2019年11月10日 bisha mining process plant grinding sag mill. AG/SAG mills are normally used to grind run-off-mine ore or primary crusher product. Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids. 2D and 3D simulations of particles in a SAG Mill.

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise ensures delivery of your Premier™ mill or Select™ mill based on your operational needs. When choosing your equipment we not only keep in mind mill performance, but

Dynamic modeling and simulation of a SAG mill-pebble

2018年10月1日 The dynamic model of an AG/SAG mill includes several interlinked sub-process modules, and these modules can be updated individually. As shown in Fig. 1, the mill is divided into n sections, where m is the section number and q is the transported material. All sections have the same length, and each section contains a dataset of

(PDF) DRILL-TO-MILL PLANT OPTIMIZATION AT

2019年9月22日 The grinding circuit consists of a semi-autogenous (SAG) mill with a pebble crusher followed by two ball mills. The SAG mill is unusual, with a low aspect ratio similar to the ball mills.

(PDF) FULL PRE-CRUSH TO SAG MILLS ResearchGate

2015年9月20日 SAG mill compared to crusher and ball mill product size distributions (Powell et al 2014) SSE plot for a range of processing equipment Summary of circuit performance data from example mines

Precedent-setting case against Canadian company for its

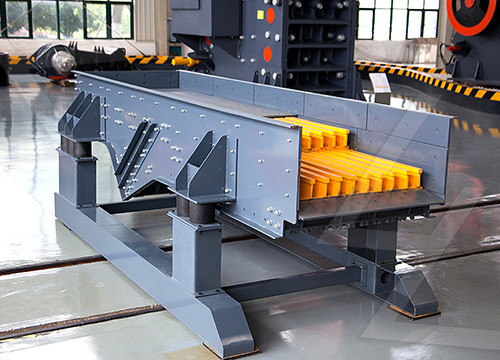

2020年10月24日 A general view shows the sag mill and ball mill within the processing plant at the Bisha Mining Share Company (BMSC) in Eritrea, operated by Canadian company Nevsun Resources, on Feb. 18, 2016. Nevsun Resources’ gold and copper mine in the Bisha mining district in northern Eritrea, adjacent to Sudan. (CBC) Requests to Zijin

SAG Mill Grinding Circuit Design Mineral

2016年6月6日 Single stage AG/SAG milling. AG/SAG mills as a primary grinding stage in a circuit with or without additional stages of comminution. Inclusion of pebble-crushing circuits in the AG/SAG circuit. Circuits

IMPROVEMENTS IN SAG MILL THROUGHPUT FROM

2018年2月20日 Ahafo have been working with Metso Process TechnologyInnovation (PTI) since early 2009 to increase mill throughput from a combination of controlled blasting practices and optimised primary crusher and grinding circuit conditions. For such Mine-to-Mill projects, PTI’s methodology is termed Process IntegrationOptimisation (PIO).

Optimizing your SAG mill operation International Mining

2007年3月21日 Elimination of material transport problems using TPL will bring the following process benefits: • Ensure good grinding conditions with lower grinding energy per tonne. • Can be easily retro-fitted to existing mills. The optimal performance of AG/SAG mills is the key to successful plant operation.

How it Works: Crushers, Grinding Mills and

2017年6月2日 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the

Ing. Steve Adjei-Laryea Group Manager Asset

Jan 2022 Present1 year 3 months. Abidjan, Côte d’Ivoire. Lead in the development, implementation, and management of a group wide asset management framework for mine to mill equipment mobile, fixed processing plants and infrastructure to achieve optimum uptime for production. Operational span: 7 operating mines, 3 countries.

bisha mining process plant grinding sag mill

2019年11月10日 bisha mining process plant grinding sag mill. AG/SAG mills are normally used to grind run-off-mine ore or primary crusher product. Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids. 2D and 3D simulations of particles in a SAG Mill.