Spring Compression Kit For Coal Mill In Chile Coal Processing Plant

Coal Washing Plant, Equipment Mineral

2021年12月29日 Coal Washing Plant. 1. Coal, contain with clay. 2. Feeding size 0-150mm. 1. Excavator or loader feed raw materials to the

Coal Mill Coal Mill In Cement Plant AGICO Cement

The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or vertical mill system

coal mill pressure spring set Capabuild

Coal Pulverizer Patented Grinding Pressure Monitor System. More. This device monitors your grinding pressure at each of the grinding locations with a load cell. This information

spring compression kit for coal mill in zimbabwe coal

What Is A Coal Processing Plant . Steam WorkshopCoal Processing Plant. coal processing plant it is intended for processing of coal. largescale industry180 jobs. with a capacity of

Central Africa Spring Compression Kit For Coal Mill In

Coal mill for power plants manufacturer mpl produces vertical mill,Raymond mill,Super-micro mill and MTM mill for sale in Coal-fired Thermal Power Plant .Coal mills such

spring compression kit for coal mill in india

2020年2月4日 spring compression kit for coal mill in india. 2020-11-10 spring compression kit for coal mill in india. There are forty years of manufacturing history, with

spring compression kit for coal mill in india coal

spring compression kit for coal mill in india coal processing plant Welcome to TotalEnergies South Africa Fuel Prices Inland Fuel prices as of 5 January 2022 Petrol Unleaded 93

spring compression kit for coal mill in bolivia

2020年12月22日 There are forty years of manufacturing history, with three major production bases,over 160 senior R&D engineers and 600+ large and medium-sized

spring compression kit for coal mill in india coal

A. Coal Handling Plant Coal transported to the plant by the rail line and carrier trucks. This coal is transfer from the underground bunker to crusher by series of conveyer belt. In

Coal Pulverization System: Explosion Prevention and

2017年1月5日 designing and operation of the coal process system. 1. Hazard analysis of the process The process is shown as Figure 1. Raw coal is conveyed from the storehouse by a belt conveyer. Then it is lifted to the entrance level of a vertical cylindrical mill by a bucket elevator, and an electromagnet is used to remove iron objects from the raw coal.

Coal Phase-out in Chile Energy Partnership

On June 4th, 2019, then Chilean President Sebastian Piñera announced the start of the phase-out with the decommissioning of eight coal-fired power plants by 2024. Official protocols have been signed with each of the four coal-fired power plant operators, in which the companies agree to decarbonize and declare their willingness to invest in

(PDF) Control for pulverized fuel coal mill

2015年10月1日 This stone focuses on the flow control of pulverized fuel (pf flow) of the coal mill. The control performance given by the conventional PID, Fuzzy-PID and I minus P minus D (I-P-D) controllers for

(PDF) Modeling and Parameter Identification of

2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994). In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup

Coal Washing Plant, Equipment Mineral

Coal Washing Plant. 1. Coal, contain with clay. 2. Feeding size 0-150mm. 1. Excavator or loader feed raw materials to the hopper of trommel scrubber, here trommel scrubber with 2 layers screen at the end. After washing off

Coal Mill In Cement Plant, Air-swept Coal Mill Coal Mill

The coal mill adopts an edge driving system, is driven by the motor through the reduction gear and large and small gears. Raw coal is fed into feeding device of coal mill in cement plant, the hot air with temperature about 300 ℃ through the duct into the feeding device, there is a special lifting board in drying storehouse board will raise the raw coal, and

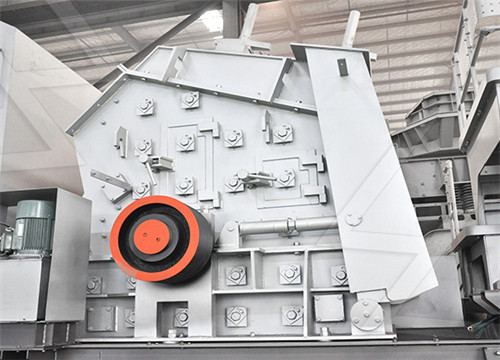

Coal crusher machine,coal grinding mill plant, mobile coal

mpl supply a whole set of coal crushing production line to coal processing industry. Coal mill is the most important coal processing plant as coal is usually fed into fire power plant to generate energy. mpl vertical coal mill is the one we designed for coal pulverizing and is featured with high capacity, high efficiency and long service time.

The End Of An Era: The Martin Drake Coal Plant

2021年8月26日 Colorado Springs Utilities provides electricity to nearly 240,000 homes and businesses, using a variety of energy sources, from natural gas, to solar, wind, hydro, and for at least a few more

Pulverized Coal Pipe Testing and Balancing

2010年10月7日 Isokinetic sampling of each coal pipe allows the test engineer to identify relative pipe-to-pipe fuel balance, airflow balance, and air/fuel ratios that standard testing techniques can’t. Source

mill/sbm coal pulverizer springs.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

Chile looks to repurpose its coal-fired power plants

2021年5月5日 Currently, Chile has an installed power generation capacity of 24,886mw. Up until November 2020, coal-fired plants were responsible for almost 18%, the main source of energy generation, followed by diesel oil and natural gas, each with a share of around 15%. Therefore, the government's plan to cease operations of 11 coal-fired plants (30%)

Coal Phase-out in Chile Energy Partnership

On June 4th, 2019, then Chilean President Sebastian Piñera announced the start of the phase-out with the decommissioning of eight coal-fired power plants by 2024. Official protocols have been signed with each of the four coal-fired power plant operators, in which the companies agree to decarbonize and declare their willingness to invest in

Coal ProcessingHandling Equipment FEECO

We offer a variety of custom agglomeration equipment for processing coal. Our pin mixers are an ideal fit for de-dusting applications. When combined with our disc pelletizers, coal fines can be processed into a pelletized product. Pug mills (paddle mixers) and briquetters for processing coal fines into briquettes are also available.

AES Accelerates 1 GW of Coal Plant Retirements in Chile

2021年7月7日 First 1-GW Unit of Major China Coal-Fired Plant Comes Online. A Chinese power company said the first of four 1,000-MW units at a new coal-fired power plant in. U.S. Coal Plant Closures Continue

Coal Washing Plant, Equipment Mineral

Coal Washing Plant. 1. Coal, contain with clay. 2. Feeding size 0-150mm. 1. Excavator or loader feed raw materials to the hopper of trommel scrubber, here trommel scrubber with 2 layers screen at the end. After washing off

Vertical Coal Mill for Coal Grinding in Cement Plant

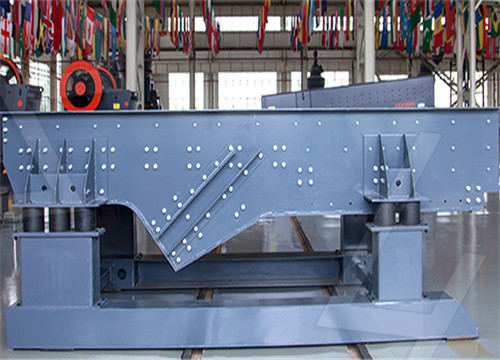

Vertical Coal Mill. Feeding size: ≤110mm. Capacity: 5-70t/h. Motor power: 110-1400kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plant. Email: info@ballmillssupplier.

Coal Processing Equipment

Allied-Locke Industries. Dixon, IL Manufacturer* $50 99.9 Mil 1965 200-499. ISO 9001 certified manufacturer of coal processing equipment. Products include pintle chain attachments, pintle chains, sprockets, steel hubs, and traction wheels for coal preparation and processing systems. Equipment made of stainless and alloy steel.

Coal mill pulverizer in thermal power plants

2012年11月17日 3. 2.Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the

Coal Mill PDF Mill (Grinding) Troubleshooting Scribd

2018年4月5日 Coal mill Donts: Do not get in to the mill when the motor is not isolated and the discharge valves closed Do not use steel hammers on rolls Do not use direct flame torch for bearing assembly Donts: the mill. Do not alter classifier setting ,spring compression setting, roll ring settings, ringring-roll clearance etc. Do not carry out maint.