Cement Mill Grinding Media Calculations Rock Crushing Plant Veitnam

Cement grinding optimisation ScienceDirect

2004年11月1日 Due to limitation of the mill’s rotational speed, the smallest ball size is usually restricted to about 15 mm. Cement grinding using stirred mills (Pilevneli and

ball mill calculations, grinding media filling degree, ball

online live calculators for grinding calculations, Ball mill, tube mill, critical speed, Degree of filling balls, Arm of gravity, mill net and gross power

(PDF) Grinding in Ball Mills: Modeling and

2012年6月1日 The stone presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial

Cement Mill Cement Grinding Machine AGICO Cement

Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement

en/cement mill media for crushing rock.md at main

Contribute to dinglei2022/en development by creating an account on GitHub.

crusher design calculation Crushing and Screening Plant

Crushing Plant Design and Layout Considerations. 3 Table 2 Production Requirements Typical Example: 60” x 89” primary crushermill feed conveyor system Operating

cement mill calculations MiningQuarry Plant

Grinding Plant; News; Service; cement mill capacity calculator-[crusher and mill] bmw can supply you all kinds of mining rusher, mills equipments cement mill grinding media

velocity calculation in cement mill MiningQuarry Plant

2013年3月19日 cement ball mill grinding media calculation. grinding media for raw and cement mills; ball mill critical speed calculation. ball mill critical speed how to

f.c. crushing and grinding calculations Grinding Mill China

?stone crushing plants in the united states of america ?second hand small cement mill ?vertimill grinding mills pdf Mining Production Line Construction. f.c. crushing and

Cement Plants located in Vietnam The Global Cement

Cement plant locations and information on Vietnam can be found below. For full access to the database, purchase The Global Cement Report™, 14th Edition. Purchase. Summary. Cement capacity (Mt) Integrated plants. 67. Clinker plants. 1.

11.19.2 Crushed Stone Processing and Pulverized

2015年9月10日 Some stone crushing plants produce manufactured sand. This is a small-sized rock product with a maximum size of 0.50 centimeters (3/16 th inch). Crushed stone from the tertiary sizing screen is sized in a vibrating inclined screen (fines screen) with relatively small mesh sizes. Figure 11.19.2-1:

(PDF) Cement grinding optimisation Alex Jankovic

These models can be used to simulate cement grinding circuits and to assist their optimisation. The “work horse” of the cement grinding plant is the two-compartment ball mill, commonly called the tube mill. Significant advances in model development were achieved in recent years (Benzer et al, 2001, 2003) through research on industrial scale.

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

In another word, the cement grinding mill can increase the cement quality and guarantee the qualification rate of cement. In general, cement mill can both apply for dry cement production and wet cement production. Commonly, there are three hot types of cement mill in the cement industry: cement ball mill, Raymond mill, and vertical cement mill.

Hammer Mill CrusherGrinder Mineral

2016年2月25日 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion

crusher design calculation Crushing and Screening Plant

Crushing Plant Design and Layout Considerations. 3 Table 2 Production Requirements Typical Example: 60” x 89” primary crushermill feed conveyor system Operating schedule calculation for 3 x 8 hours per shift. crusher design calculation pdf Newest Crusher, 9/10 3.2K Reviews.

en/cement mill capacity calculation solution for ore

Contribute to dinglei2022/en development by creating an account on GitHub.

velocity calculation in cement mill MiningQuarry Plant

2013年3月19日 cement ball mill grinding media calculation. grinding media for raw and cement mills; ball mill critical speed calculation. ball mill critical speed how to calculate cement mill critical speed Crusher South

bond crushing and grinding calculations part i and ii

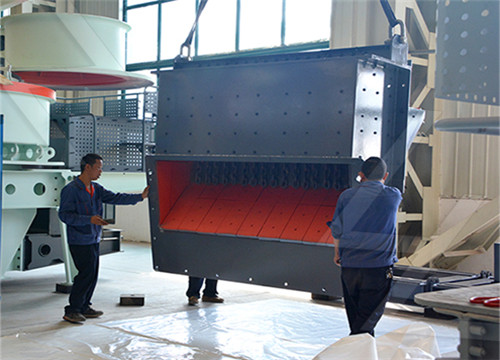

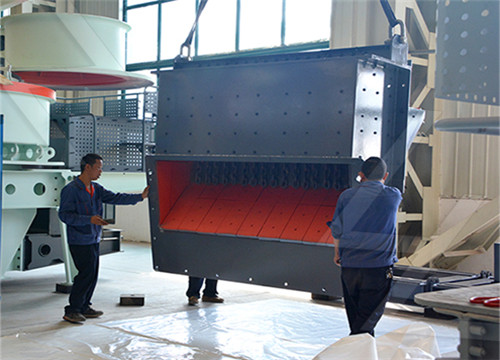

We proposed the following equipments to our client: vibrating feeder, jaw crusher, impact crusher, vibrating screen and belt conveyor. The client approved Gulin proposal and close the deal at last. Our engineer spent one month on installation and test run of the whole crushing plant. Besides, the local workers are trained well by our engineer.

Materials Free Full-Text Simulation of Electrical and

Minerals are familiar to us in our daily lives and are used in various fields (e.g., ceramics, pharmaceuticals, cosmetics) [].In order to extract minerals from rocks, a combination of mechanical comminution methods of crushing and grinding (e.g., ball mill) based on compression, impact and shearing mechanisms are generally used [].The energy

Cement in Vietnam Global Cement

2012年4月19日 Cement Future. With cement inventory indices up by 64% year-on-year in 2011, Vietnam is again looking to export large quantities of cement in 2012. The country is officially forecast to export 0.5Mt of cement and 5.5Mt of clinker in 2012, according to an official from the Vietnam National Cement Association (VNCA).

Rock Crusher MachinesPulverizers Williams Crusher

Williams Patent Crusher understands that every crushing and grinding job is different. We strive to make sure every machine we construct is a custom solution that gets a specific job done right. Our expertise in rock crushing is why we’ve been an industry leader for over 150 years. Our engineers have designed a catalog of rock and stone

Materials Free Full-Text Simulation of Electrical and

Minerals are familiar to us in our daily lives and are used in various fields (e.g., ceramics, pharmaceuticals, cosmetics) [].In order to extract minerals from rocks, a combination of mechanical comminution methods of crushing and grinding (e.g., ball mill) based on compression, impact and shearing mechanisms are generally used [].The energy

Cement Grinding Cement Plant Optimization

Water Spray in Cement Mills. Water spray installed generally in second compartment of ball mill to control cement temperature. Cement discharge temperature should be kept below about 110 o C but, the same time should allow some 60% dehydration of gypsum to optimize cement strength without excessive false set.

Cement Ball Mill JXSC Machine

2019年12月10日 The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and

(PDF) Calculation method and its application for energy

2020年2月26日 For QMP-10T ball mill, the grinding media and raw materials are gradually mixed in the fi rst six seconds after the ball mill is started, which consumes an average

cement consumption calculation spreadsheet Mining

2013年8月30日 grinding media charge calculation in cement 8.1 Calculation of Cement Mill Power Consumption 8.2 the spreadsheet allows for the calculation of the PCA Report on Sustainable Manufacturing PCA The Portland

crusher design calculation Crushing and Screening Plant

Crushing Plant Design and Layout Considerations. 3 Table 2 Production Requirements Typical Example: 60” x 89” primary crushermill feed conveyor system Operating schedule calculation for 3 x 8 hours per shift. crusher design calculation pdf Newest Crusher, 9/10 3.2K Reviews.

sbmchina/sbm useda ball mill for grinding line 200

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Grinding Media Union Process

Zirconium Oxide Balls (95% ZrO2) are the strongest, best wearing ceramic media for metal-free, pharmaceutical and processing grinding. These balls have a white, shiny appearance. They are also available in 3⁄8″ and

- Mobile Copper Floatation

- 生产焦煤设备

- 膨胀石墨制砂设备

- 水泥厂 熟料加工

- 莹石矿上市企业

- 1513hd颚式破碎机报价

- Single Spiral Classifier For Mineral Processing

- 贵州信息二手市场球磨机

- 煤矿开办手续有哪些

- Aarush Industries Indore Stone Crusher

- 山西大同有矿山机械市场吗

- Indirect Impacts Of Lithium Extraction

- 大理石加工工人制度

- Investors Willing To Partner With Mining Company In Nigeria

- 颚式破碎机带轮怎样匹配