Sag Mill For Mineral Processing

Grinding Mills Mineral Processing Equipment

2022年3月18日 High cost-effectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi

SAG Mill Grinding Circuit Design Mineral Processing

Semi Autogenous Design FactorsSag Mill Operation ExampleProcess Plant DescriptionSag Mill Design and SpecificationOperating Problems Since CommissioningDesign Changes and Future Operating Strategies

The design of large mills has become increasingly more complicated as the size has increased and there is little doubt that without sophisticated design procedures such as the use of the Finite Element method the required factors of safety would make large mills prohibitively expensive. In the past the design of small mills, up t在911metallurgist上查看更多信息预计阅读时间:12 分钟

AG Mill&Sag Mill for Mineral Processing Operation

2023年2月23日 AG Mill&Autogenous Mill&SAG Mill: 1.CITICIC can produce below 12m AG Mill&SAG Mill 2.AG Mills&SAG Mills:2.4x1.2~13x4.0m ZTIC can produce below 12m autogenous mills(AG Mill) and semiautogenous mills(SAG Mill).autogenous / semiautogenous mills(AG Mill &SAG Mill) are utilized to grind run-of-mine rock or primary

SAG mill goldcilplant

Development of SAG Process. With the increasing of mineral processing plants' scale and the demand for automation, the manufacturing process and operation of SAG mill are more and more mature. The running

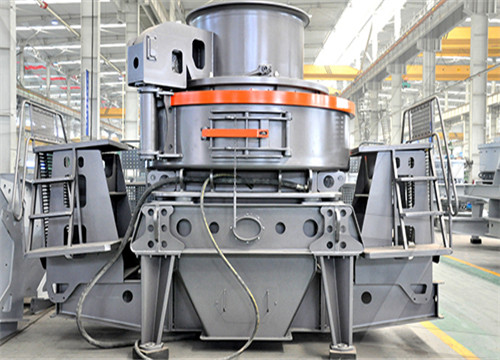

AGSAG Mill for Mineral Processing WetAerofall SAG

AG Mill and SAG Mill. Feeding size: ≤25mm. Capacity: 0.65-615t/h. Output size: 0.074-0.89mm. Applications: It is commonly used in the mineral processing industry and ferrous and non-ferrous metal ore and nonmetal ore processing plants. It can also be used in cement plant, refractory plant, fertilizer plant and smelting plant.

SAG vs. AG Mills: Understanding the Key Differences

SAG mills use a combination of steel balls and rock particles as grinding media, while AG mills use only the ore itself. Both types of mills are used for grinding ore in mineral processing operations, but SAG mills are larger in size and can grind larger quantities of ore. AG mills, on the other hand, are smaller and are typically used for

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise ensures delivery of your Premier™ mill or Select™ mill based on your operational needs. When choosing your equipment we not only keep in mind mill performance, but

SAG Milling MetallurgistMineral Processing Engineer

2023年3月9日 The main drawback of SAG high power consumption. To reduce power consumption, I think: The right determine of SAG feed size. This depends on the mill diameter and the ball size. Feed size necessary to take 80% of the maximum piece of ore that will crushed by the balls. For the big SAG more than 8 meters optimal feed size will

SAG Mill for Small Operation MetallurgistMineral

2022年12月28日 Is it advisable to use a SAG mill for small, say 2000 TPD concentrator operations? The processing, in this case, is a complex zinc/tin mineral and we are afraid a SAG would P80 produces too much fines (since the tin is to soft brittles) (tin cassiterite).The mineral is marmatite and casiteritre

Differences in Properties between Pebbles and Raw Ore

2022年6月17日 Consequently, pebbles significantly affect the efficiency of mineral processing production. The discrete element method (DEM) is often used to analyze the grinding process of SAG mills; it also helps us understand the origins of pebbles [5,6,7,8]. According to the previous DEM analysis, it can be concluded that the primary mode of

Grinding Mills Mineral Processing Equipment

2022年3月18日 High cost-effectiveness CITIC HIC grinding mills are recognized as China's Manufacturing Industry Single Champion Product. CITIC HIC is responsible for setting the national standards of semi

Mill Filling Prediction tool addresses

2020年4月2日 SAG mills are a key asset for mineral processing operations as one of the critical stages of extracting mineral out of ore, and their continued stable operation is central to productivity. However, the

Estimation of load level in industrial SAG mills using the

2016年10月26日 The method can be applied for any kind of synchronous mill motor.Results of an actual application are presented, namely for a 15 000 Hp SAG mill showing a good correlation with the filling

AG Mill&Sag Mill for Mineral Processing Operation

2023年2月23日 AG Mill&Autogenous Mill&SAG Mill: 1.CITICIC can produce below 12m AG Mill&SAG Mill 2.AG Mills&SAG Mills:2.4x1.2~13x4.0m ZTIC can produce below 12m autogenous mills(AG Mill) and semiautogenous mills(SAG Mill).autogenous / semiautogenous mills(AG Mill &SAG Mill) are utilized to grind run-of-mine rock or primary

Minerals Free Full-Text Application of Data Analytics

2019年5月16日 Understanding these relationships is key to building 3D spatial models that relate mineral processing performance to the physical variability Mining and Milling Optimisation of the Existing and New SAG Mill Circuit. In Proceedings of the 4th SAG Conference, Vancouver, BC, Canada, 23–27 September 2006; Department of Mining

Empirical Model of Recovery Response of Copper Sulphide

2018年11月1日 Finally, a proposal was made for the development of a simulation model under MODSIM®, a flexible tool for mineral processing applications. This was to test the limitations of the empirical model for future refinement. SAG mill throughput, ball mill load, and tonnage of feed material to the SAG mill in the -125 +63 mm size fraction

What’s the Difference Between SAG Mill and Ball Mill

2019年11月26日 The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 0.1 mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill’s

Influence of feed size on AG / SAG mill performance

@inproceedings{Morrell2001InfluenceOF, title={Influence of feed size on AG / SAG mill performance}, author={Stephen Morrell and Walter Valery}, year={2001} } S. Morrell, W. Valery; Published 2001; Materials Science; No Paper Link Available. Save to Library Save. Create Alert Alert. Cite. Share This Paper. 25 Citations.

High-performance Dry Grinding/wet Grinding Can Be

High-performance Dry Grinding/wet Grinding Can Be Customized For Mineral Processing,Find Complete Details about High-performance Dry Grinding/wet Grinding Can Be Customized For Mineral Processing,Variety Grinding Equipment,High Efficiency Ball Mill Industrial/mining,Discount Price Grinder Machine Mine from Supplier or Manufacturer

(PDF) Operation Analysis of a SAG Mill under Different

2020年10月9日 The indispensable technical mean in mineral processing, i.e., grinding technology, is widely. in this , the working process of the laboratory-scale SAG mill is taken as the research

AG Mill&Sag Mill for Mineral Processing Operation

2023年2月23日 AG Mill&Autogenous Mill&SAG Mill: 1.CITICIC can produce below 12m AG Mill&SAG Mill 2.AG Mills&SAG Mills:2.4x1.2~13x4.0m ZTIC can produce below 12m autogenous mills(AG Mill) and semiautogenous mills(SAG Mill).autogenous / semiautogenous mills(AG Mill &SAG Mill) are utilized to grind run-of-mine rock or primary

Empirical Model of Recovery Response of Copper Sulphide

2018年11月1日 Finally, a proposal was made for the development of a simulation model under MODSIM®, a flexible tool for mineral processing applications. This was to test the limitations of the empirical model for future refinement. SAG mill throughput, ball mill load, and tonnage of feed material to the SAG mill in the -125 +63 mm size fraction

SAG millinggrinding pilot plants alsglobal

The larger units can also be matched with the SAG mill in SAB/SABC configuration. Stirred mills (Regrinding). Finer regrinding or ultra-fine grinding is a frequent requirement in pilot plants and ALS has a range of units that can run continuously in pilot applications. The following mills are located at Balcatta: ISAMill tm,Deswik, and

SAG mills Archives International Mining

2023年3月2日 has been chosen to supply the SAG mills, ball mills and cyclones to Josemaria Resources’ 150,000 t/d copper-gold project in the San Juan Province of Argentina. Chairman, RME, says: “When the first-generation THUNDERBOLT was released in 1997, it was a game changer for the minerals processing industry. As the

Minerals Free Full-Text Application of Data Analytics

2019年5月16日 Understanding these relationships is key to building 3D spatial models that relate mineral processing performance to the physical variability Mining and Milling Optimisation of the Existing and New SAG Mill Circuit. In Proceedings of the 4th SAG Conference, Vancouver, BC, Canada, 23–27 September 2006; Department of Mining

Grinding Mill Computer Model AusIMM

2021年6月24日 design of mineral processing plants. This group cover the mill designs of A.M., R.M., B.M., and pebble mill designs. The programme is an EXCEL 5 workbook split into a number of spreadsheets which include the calculation sheets for printout and presentation, a graph showing the mill design relative to the minimum required and a

Influence of feed size on AG / SAG mill performance

@inproceedings{Morrell2001InfluenceOF, title={Influence of feed size on AG / SAG mill performance}, author={Stephen Morrell and Walter Valery}, year={2001} } S. Morrell, W. Valery; Published 2001; Materials Science; No Paper Link Available. Save to Library Save. Create Alert Alert. Cite. Share This Paper. 25 Citations.

High-performance Dry Grinding/wet Grinding Can Be

High-performance Dry Grinding/wet Grinding Can Be Customized For Mineral Processing,Find Complete Details about High-performance Dry Grinding/wet Grinding Can Be Customized For Mineral Processing,Variety Grinding Equipment,High Efficiency Ball Mill Industrial/mining,Discount Price Grinder Machine Mine from Supplier or Manufacturer