Vibratory Grinding Quality

Development of Control System for Vibratory Grinding

2017年1月1日 However, in grinding vibration (Chatter) between wheel and workpiece poses challenges in maintaining process requirements. A wide range of investigations have been carried out to detect and avoid this dynamic phenomenon that affects

Process Performance of Low Frequency Vibratory

A porous aluminium oxide-grinding wheel was used for the experimental improved the overall process performance. A reduction of over 30% in grinding cutting forces was

Vibratory Grinding Rohde AG Aluminum, stainless steel

One of the most customary processes to deburr and/or precision-grind the surfaces of loose bulk items and machine components is vibratory grinding. Here the parts to be processed

进一步探索

A Guide To Vibratory Finishing Media Sharretts Plating CoThe Vibratory Finishing 101: A Layman’s Guide Inovatec M根据热度为您推荐•反馈

Vibratory Grinding OSK Kiefer GmbHOSK Kiefer GmbH

Advantages of vibratory grinding: The surface finish after shot peening can be improved by laping, honing, polishing, vibratory grinding, etc., as long as the temperature indused

Modelling and Optimization of Vibratory Finishing Process

1996年1月1日 Modelling. Modelling and Optimization of Vibratory Finishing Process F. Hashinioto, Timken Research, The Timken Company, Canton, OH, USA Submitted by D.

Development of Control System for Vibratory Grinding

2017年12月31日 The vibratory grinding gave better surface finish than conventional though this was marginal. High quality surfaces with roughness less than 0.1 μm were

New Technologies for Vibratory Grinding General

2019年5月16日 Grinding can be done in batches, or in a continuous flow process (which is more common). First, material enters one end of a vibratory grinding mill drum into

The Vibratory Finishing 101: A Layman’s Guide

2020年7月6日 The vibratory finishing process involves basic kinematics (motion of objects) and components in the system. Components include bowls that have different sizes — 1/3 meter to over 1 meter, depending

VIBRATORY GRINDING seltertech

Vibratory finishing is a mechanical-chemical process for treating various types of surface materials. The work pieces are placed in a tank with grinding tools called chips. They are then processed in a vibratory or

vibratory grinding 英中 Linguee词典

2007年3月30日 大量翻译例句关于"vibratory grinding" 英中词典以及8百万条中文译文例句搜索。 翻译器 Translate texts with the world's best machine translation technology,

Development of Control System for Vibratory Grinding

2017年1月1日 However, in grinding vibration (Chatter) between wheel and workpiece poses challenges in maintaining process requirements. A wide range of investigations have been carried out to detect and avoid this dynamic phenomenon that affects wheel/workpiece interaction leading to uneven wear and poor workpiece quality.

Potentials of Vitrified and Elastic Bonded Fine Grinding

2021年1月5日 Continuous generating gear grinding with vitrified grinding worms is an established process for the hard finishing of gears for high-performance transmissions. Due to the increasing requirements for gears in terms of power density, the required surface roughness is continuously decreasing. In order to meet the required tooth flank

抛光(滚磨处理) Rohde AG Quality for Industry 蚩尤

A large number of different abrasives offer a wide range of applications. The processing times vary here from approx. 1-8 hrs. or more depending on the requirement and material. Maximum workable size of item in mm. Vibratory grinding in. circular machines. ca. Ø100 x 280. ca. Ø280 x 100. Vibratory grinding in. vat machines.

Development of Control System for Vibratory Grinding

2017年12月31日 The vibratory grinding gave better surface finish than conventional though this was marginal. High quality surfaces with roughness less than 0.1 μm were obtained stably up to a cutting

China Vibration Mill, Vibration Mill Manufacturers,

Trunnion Bearing Ball Mill Design Pdf Vibration Stone Grinding Mill, Good Quality Drying Coal Grinding Ball Mill Price . US$ 10000- / Piece (FOB Price) Mineral Small Vibration Mill/Vibratory Pulverizer/Laboratory Vibratory Grinding Mill. US$ 2380-3000 / Piece (FOB Price) 1 Piece (MOQ)

Vibratory finishing machine All industrial manufacturers

grinding vibratory finishing machine TB-300BC. polishing deburring industrial. Contact. Power: min 3.7 kW. Rotational speed: min 1450.0 rpm. Vibration grinding machine with muffler cover 1. High output, high effificiency, energy saving, long life, low noise, no pollution, high quality. 2.

China Vibratory Finishing Machine, Vibratory Finishing

China Vibratory Finishing Machine manufacturers Select 2023 high quality Vibratory Finishing Machine products in best price from certified Chinese Casting, Grinding Machine suppliers, wholesalers and factory on Made-in-China

Laboratory Vibratory Grinding Mill High Manganese Steel

1 Laboratory Vibratory Grinding Mill High Manganese Steel Vibration Pulveriser Machine, Find Details and Price about Sample Pulverizer Sample Herb Grinder from Laboratory Vibratory Grinding Mill High Manganese Steel Vibration Pulveriser Machine Jiangxi Victor International Mining Equipment Co., Ltd.

Pulverizing Vibratory Pulverizer Laboratory Disk

2014年10月9日 Vibratory Pulverizer is also called Vibratory Cup Mill or Ring and Puck Mill. Laboratory Disk Pulverizer Laboratory Disk/Disc Pulverizer can be used for intermittent and continuous fine grinding of hard-brittle and medium-hard materials in the field of mining and metallurgy, glass industry, ceramics industry.

表面处理grinding是什么意思_百度知道

2015年3月7日 2011-08-15 Vibratory grinding是什么表面处理 2017-01-22 Grinding翻译成中文是什么意思 2015-01-31 求问大神铝型材表面处理工艺英文术语 2013-11-25 我想问下美国标准的一些零件所对应的中国标准是什么?

Development of Control System for Vibratory Grinding

2017年1月1日 However, in grinding vibration (Chatter) between wheel and workpiece poses challenges in maintaining process requirements. A wide range of investigations have been carried out to detect and avoid this dynamic phenomenon that affects wheel/workpiece interaction leading to uneven wear and poor workpiece quality.

Potentials of Vitrified and Elastic Bonded Fine Grinding

2021年1月5日 Continuous generating gear grinding with vitrified grinding worms is an established process for the hard finishing of gears for high-performance transmissions. Due to the increasing requirements for gears in terms of power density, the required surface roughness is continuously decreasing. In order to meet the required tooth flank

Grinding and Polishing Guide Buehler Metallography

High quality sample preparation is a basic starting point for this technique. As already explained above, vibratory polishing is dedicated to fine diamond or oxide suspensions typically between 1 and 0.02 microns. Figure 3.18 Vibratory polished ferritic steel, Electron image overlayed with orientation map normal direction Phase α Iron.

Grinding and Polishing Buehler Metallography

Vibratory Polishers. The VibroMet 2 Vibratory Polisher is designed to prepare high quality polished surfaces on a wide variety of materials, including EBSD applications. The 7200 cycles per minute horizontal motion produces a very effective polishing action, providing superior results, exceptional flatness and less deformation.

Vibratory Finishing Process for Metal Deburring and

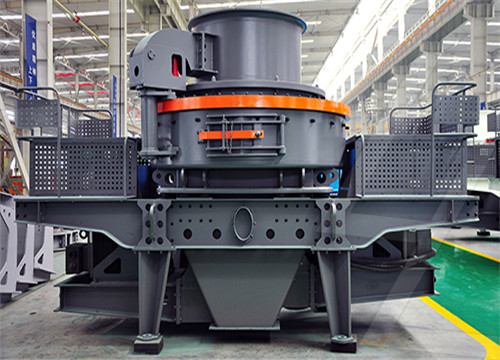

2020年5月2日 1. Vibratory Finishing Process. The entire process happens inside the vibratory finishing machine. This machine consists of a large container that will hold the parts for finishing and the finishing media. This large container is connected to an unbalanced motor and is supported by a set of springs.

Laboratory Vibratory Grinding Mill High Manganese Steel

1 Laboratory Vibratory Grinding Mill High Manganese Steel Vibration Pulveriser Machine, Find Details and Price about Sample Pulverizer Sample Herb Grinder from Laboratory Vibratory Grinding Mill High Manganese Steel Vibration Pulveriser Machine Jiangxi Victor International Mining Equipment Co., Ltd.

Vibratory Polisher Metallographic Grinding and Polishing

Vibratory Polisher. Vibratory Polisher removes minor deformation remaining after mechanical preparation revealing a stress-free surface without need for the hazardous electrolytes required by electro-polishers. Vibratory Polisher is designed to prepare high quality polished surfaces on a wide variety of materials, including EBSD applications.

表面处理grinding是什么意思_百度知道

2015年3月7日 2011-08-15 Vibratory grinding是什么表面处理 2017-01-22 Grinding翻译成中文是什么意思 2015-01-31 求问大神铝型材表面处理工艺英文术语 2013-11-25 我想问下美国标准的一些零件所对应的中国标准是什么?

Fritsch GmbH Horizontal mills All the products on

disc mill PULVERISETTE 13. horizontal glass for ceramics. Rotational speed: 440 rpm. Output: 0 kg/h 150 kg/h. Efficient premium fine grinding The premium model of the FRITSCH Disk Mill for efficient fine grinding of hard-brittle to medium-hard solids: Even safer due to the automatic locking of the collecting vessel and grinding

China Vibratory Finishing Machine Manufacturer,

Industrial Vibratory Grinding Polishing Deburring Large Media Tumbler Ireland UK FOB Price: US $6,000-9,000 / Piece. Min. Order: 1 Piece Contact Now. Video. Grinding and Heating Automatic Vibratory Mass Finishing System China Cheap Excellent Quality Ballcone Stainless Steel Deburring Media USA UK FOB Price: US $6,500-9,000 / Ton.