Enviromental Ball Mill Leaching From China

Sulfuric acid leaching of ball-milling activated FePO4

2022年11月1日 Kinetic studies showed that the apparent activation energy for leaching the as-received and the ball-milled IPR were 41 kJ/mol and 29 kJ/mol, respectively, which

A mechanochemical method for one-step leaching of

The leaching reaction remains activated, enabling the reaction to proceed rapidly and efficiently. In this study, LIBs cathode waste was placed in a ball mill tank with a

Suppressing Heavy Metal Leaching through Ball Milling

A new type of planetary ball mill with a commercial name of all-dimensional planetary ball mill (QXQM-2, Changsha Tencan Powder Technology Co., Ltd., Changsha, Hunan,

Suppressing Heavy Metal Leaching through Ball Milling of

2016年7月8日 Ball milling is investigated as a method of reducing the leaching concentration (often termed stablilization) of heavy metals in municipal solid waste

Ball milling A green and sustainable technique for the

2022年1月1日 Ilmenite is a naturally available mineral that is highly applicable in the synthesis of pure TiO 2.Titania mainly presents in four polymorphs as rutile, anatase,

Ecotoxicology and Environmental Safety

weight ratio of 1:1, ball milling time of 2 h, temperature of 80 C, and leaching duration of 120 min. This This value was 25.95% higher than that attained without ball milling and

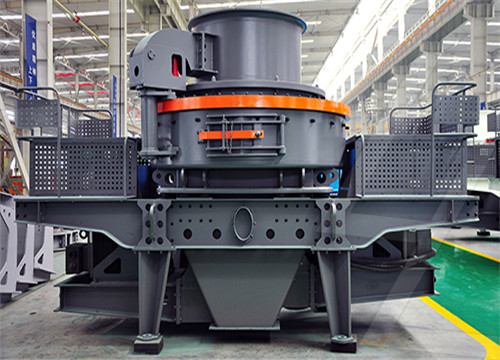

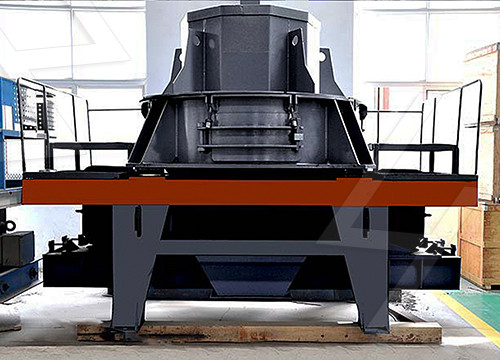

China Crusher Manufacturer, Ball Mill, Leaching Tanks

China Crusher Supplier, Ball Mill, Leaching Tanks Manufacturers/ Suppliers Henan Staurk Machinery Co, . Ltd

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉碎仪

Download. The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8

github

ball mill for acid leaching. Hydrochloric acid leaching behavior of different treated. Hydrochloric acid leaching behavior of different treated Panxi ilmenite concentrations.mille

ZHAOYUAN JINFENG GOLD MINING MACHINERY

ZHAOYUAN JINFENG GOLD MINING MACHINERY EQUIPMENT CO.,LTD. ContactMr liyan; Phone86-0535-; AddressNo.599 Wenquan Road, Zhaoyuan, Shandong

A mechanochemical method for one-step leaching of

Leaching was carried out using a planetary ball mill (QM-QX04, Nanjing Nanda, China). Fig. S2 is a schematic of the mechanical activation and structure of the ball mill. Ball milling (leaching) was carried out using different speeds (200, 300, 400, and 550 rpm), solid/liquid ratios (10, 15, 20, 30, and 50 g/L) and times (15, 30, 60, and 120 min).

Effect of Ball Mill Parameters’ Variation on the Particles of

2021年10月21日 The economic and technical values of the hydrometallurgical or leaching processing are a function of its reaction rates and these reaction rates are enhanced by mechanical activation (MA) in hydrometallurgical processing. This study presents a novel derived theoretical model for MA-assisted leaching in investigating the effects of ball mill

Suppressing Heavy Metal Leaching through Ball Milling of

Ball milling is investigated as a method of reducing the leaching concentration (often termed stablilization) of heavy metals in municipal solid waste incineration (MSWI) fly ash. Three heavy metals (Cu, Cr, Pb) loose much of their solubility in leachate by treating fly ash in a planetary ball mill, in which collisions between balls and fly ash drive various physical

Digital twin for zinc roaster furnace based on knowledge

1 Calcine unit: The zinc calcine is firstly cooled by fluidized cooler and cylinder cooler, then milled by ball mill, and finally transported to leaching process by buried scraper conveyor. • Flue gas unit: The flue gas is first cooled and recovered, then sent to the sulphuric acid production process Zhou et al. (2017).

Ball Mill, Ball Mill Manufacturer, Ball Mill Specification

2020年7月6日 Each specification has its corresponding scope of suitable and application area. The most common ore dressing ball mill specifications are Ф900×1800, Ф1200×4500, Ф1830×7000, Ф2200×6500, Ф3600×6000, Ф4500×6400, Ф5500×8500.

Ball Mill Used in Minerals Processing Plant Prominer

Ball mill Structure: Ball mill Advantages: 1、Jack-up device, easy maintenance; 2、The hydrostatic and hydrodynamic bearings ensure the smooth operation; 3、Low speed transmission is easy for starting and maintenance; 4、The oil-mist lubrication device guarantees reliable performance of bearings; 5、The air clutch adopts the flexible start

Mitigating Nitrogen Emissions From Dairy Farming

2020年5月19日 Introduction. China's growing population, dietary changes, and increasing urbanization have greatly increased the demand for dairy products, leading to rapid intensification of the domestic dairy industry ().From 2002 to 2016, dairy herd stock in China increased from 6.79 million to 15.07 million and the number of intensified farms

Metals Free Full-Text The Effects of Sulphuric Acid and

An option to improve the leaching efficiency of chalcopyrite is pretreatment prior to leaching. Pretreatment variables, such as the curing time and the addition of chloride, can increase the kinetics of copper extraction, particularly for sulphide ores. However, there has been little research on the topic. The reactions that govern this phenomenon have not been clearly

Three Common Problems and Solutions In Ball Milling

2020年6月1日 Two. Ball mill is easy to throw out pulp through throat. During the normal ball milling process, pulp is thrown out from throat with small stones. Reasons and countermeasures: (1)Imbalance of water-material ratio in ball mill. The water amount in ball mill cylinder is an important index in ball milling process. It reflects the carrying energy

github

ball mill for acid leaching. Hydrochloric acid leaching behavior of different treated. Hydrochloric acid leaching behavior of different treated Panxi ilmenite concentrations.mille

A mechanochemical method for one-step leaching of

Leaching was carried out using a planetary ball mill (QM-QX04, Nanjing Nanda, China). Fig. S2 is a schematic of the mechanical activation and structure of the ball mill. Ball milling (leaching) was carried out using different speeds (200, 300, 400, and 550 rpm), solid/liquid ratios (10, 15, 20, 30, and 50 g/L) and times (15, 30, 60, and 120 min).

A cleaner and efficient extraction of Mn from low-grade

2021年10月1日 High acid consumption is a common problem in the treatment of low-grade Mn carbonate ores by H 2 SO 4 leaching process. In this study, Fe 2 (SO 4) 3 solution was used to replace the commonly used H 2 SO 4 solution as a leaching agent to leach Mn from low-grade Mn carbonate ores, and therefore the acid consumption was reduced.

Recovery of high-grade copper from metal-rich particles

2022年8月12日 Fangfang Liu a Guangdong Key laboratory for Advanced Metallic Materials Processing, South China University of Technology, Guangzhou, People’s Republic of China;b Department of Electromechanical Engineering, Guangdong University of Science and Technology, Dongguan, People’s Republic of ChinaView further author information,

Effect of Ball Mill Parameters’ Variation on the Particles of

Request PDF Effect of Ball Mill Parameters’ Variation on the Particles of a Mechanical Activation-Assisted Leaching: A Hydrometallurgical Mechanics The economic and technical values of the

Gold Processing Plant Prominer (Shanghai)

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation

Digital twin for zinc roaster furnace based on knowledge

1 Calcine unit: The zinc calcine is firstly cooled by fluidized cooler and cylinder cooler, then milled by ball mill, and finally transported to leaching process by buried scraper conveyor. • Flue gas unit: The flue gas is first cooled and recovered, then sent to the sulphuric acid production process Zhou et al. (2017).

Ball Mill, Ball Mill Manufacturer, Ball Mill Specification

2020年7月6日 Each specification has its corresponding scope of suitable and application area. The most common ore dressing ball mill specifications are Ф900×1800, Ф1200×4500, Ф1830×7000, Ф2200×6500, Ф3600×6000, Ф4500×6400, Ф5500×8500.

Grinding Balls and Other Grinding Media: Key consumables

2021年1月25日 Tower Mills: 0.5”-1.5” grinding balls are recommended. The normal top size of media used is 10-25mm, but even smaller grinding balls can be used for very fine grinding. Isa Mills: <0.1” grinding balls are recommended. The Isa Mill is more efficient when using small media (i.e. high-chrome steel balls).

Leaching of heavy metals from contaminated soils: an

2004年8月15日 In this , we characterize the leaching of heavy metals (Ni, Cu, Zn, Cd, and Pb) from eight contaminated soils over a wide range of pH (pH 0.4-12) using an original approach based on batch pH-static leaching experiments in combination with selective chemical extractions and geochemical modeling. The leached concentrations of the