What Is Coal Mill In Cement Plant

Coal Mill in Cement Plant

It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are air-swept ball mills and vertical roller mills. At present,

进一步探索

Coal Mills in Thermal Power Plant PDF Mill (Grinding) ScCoal mill pulverizer in thermal power plants SlideShare根据热度为您推荐•反馈

Coal for cement: Present and future trends Global Cement

Coal OverviewCoal Production and Market DataInternational Coal TradingRecent Trends and EventsEgyptLooking to The FutureUnited Nations General AssemblyOECD Export CreditsThe Paris AgreementAttempts at Forecasting

The World Coal Association has estimated that there are 892Bnt of coal reserves in the world, which, at current production levels, will last around 110 years.1Coal reserves exist in most countries, although the biggest deposits can be found in the US, China, Russia and India. Coal is formed when vegetation is subjected to high pressures and tempera...

Coal Mill Coal Mill In Cement Plant AGICO Cement

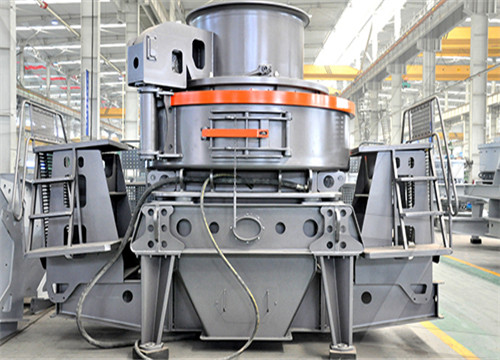

The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or vertical mill system

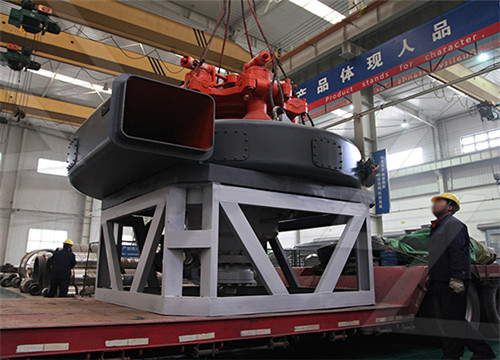

Coal Mill In Cement Plant, Air-swept Coal Mill Coal Mill

The coal mill adopts an edge driving system, is driven by the motor through the reduction gear and large and small gears. Raw coal is fed into feeding device of coal mill in cement

Coal Mill an overview ScienceDirect Topics

Observer-Based and Regression Model-Based Detection of Emerging Faults in Coal Mills. Peter Fogh Odgaard, Sten Bay Jørgensen, in Fault Detection, Supervision and Safety

Cement Mill Cement Grinding Machine AGICO Cement

Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement

What are the parts of a mill in a cement plant?

2023年3月6日 A cement mill is an important component of the cement manufacturing process in a cement plant. It is responsible for grinding clinker, gypsum, and other

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Raw mill is also known as cement raw mill, AGICO CEMENT supplies raw mill in cement plant,and other cement equipment with high quality and competitive price, welcome to

What is a Coal Grinding Mill ballmillssupplier

Coal grinding mills are essential components of power plants, responsible for converting raw coal into fine coal powder that is essential for efficient combustion in power plant boilers.

Cement Mill Cement Grinding Machine AGICO Cement

Coal mill is the main equipment in the pulverized coal preparation process.Because calcining top-grade cement clinker requires a stable supply of coal powder as the fuel of cement kiln, and more than 85% of pulverized coal should be finer than 200 mesh, water content less than 2%, and calorific value more than 6000Kcal/kg, therefore the pulverized coal

DISCUSSION ON SAFETY PRODUCTION OF COAL MILLING

2022年1月27日 1 Potential safety hazards in the coal mill system. 1.1 Spontaneous combustion occurs. The process of cement production determines the need to use a large amount of coal. The use of coal is mostly

Coal Mill with Industrial Solutions Fote

2022年6月14日 In India, the FTM coal mill used in a cement plant is with the production capacity of 30TPH. Fote Machinery has coal mill for sale, which has stable performance, advanced technology, simple structure

Coal Mill Safety

VG: At best, coal mill safety is not well understood and, at worst, it is ignored. When it comes to coal mill systems, most cement plant operators just presume that the supplier of the equipment knows all of the

Cement Kilns: Firing systems

2023年3月5日 The mills were limited in output to about 3.5 dry t/hr (for the No18 the largest used in cement plants), so larger kilns (>12 t/hr) needed to use two mills. In the 1930s, they started to replace existing coal

COMMON HAZARDS AND CONTROL MEASURES IN

2015年6月30日 These hazards may exist due to the failure of the. employees doing the servicing or maintenance to stop. the machine being worked on. Even if the machine has been stopped, the machine. can still

Application of Solid Wastes in Concrete Production– A

2023年3月8日 Concrete is the backbone of infrastructural developments and most widely used construction material of every country. It mainly consists of cement, fine aggregate, coarse aggregate, and water

Tyre/Coal Mill Roller/Casting Shell Chemical Cement Plant

2023年3月8日 Tyre/Coal Mill Roller/Casting Shell Chemical Cement Plant Supporting of Steel Casting Support Roller Rotary Dryer Tyre for Kiln, Find Details and Price about Rotary Kiln Support Roller Adjustment Rotary Kiln Support Roller Bearing from Tyre/Coal Mill Roller/Casting Shell Chemical Cement Plant Supporting of Steel Casting Support Roller

petcoke Cement industry news from Global Cement

2023年3月8日 Turkey: Germany’s Aunde has ordered four vertical roller mills from Loesche for a new cement plant being built in Soma. The order includes one 350t/hr raw material mill, one 30t/hr coal or 27t/hr petcoke mill and two 150t/hr clinker or granulated blast furnace slag mills. The scope of delivery also includes additional components such as water

cement plant calculations kiln, mills, quality, combustion,

Most Frequently Used Pyro Calculators Now Available Online For Evaluation and Process Control in Cement Industry. Size Calculations. Degree of filling DF%. Burning zone/Thermal loading TL. Volumetric loading VL. Material residence time in

Coal Mills for Cement Plants Loesche

2023年3月3日 LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to top-of-the-range installations. Special

CEMENT PLANT TALK-001

2019年3月23日 Coal Mill: Mill Bag filter jamming. Kiln Fluctuating Free lime in clinker. Cement Mill: Mill tripping at higher cement temperature. Such type of problem is quite common in cement plants and are responsible for daily kiln disturbances, mill feed variations and higher heat, power, grinding media, refractory consumptions in cement plant.

Coal Mill Safety

VG: At best, coal mill safety is not well understood and, at worst, it is ignored. When it comes to coal mill systems, most cement plant operators just presume that the supplier of the equipment knows all of the

Fire and Explosion Hazards in Cement

2018年2月20日 Bag filters used for the coal mill rank as one of the highest fire and explosion hazards in cement plants, due to the small particle size of the crushed coal. 3) Electrostatic Precipitators. Build-up of explosive

Tyre/Coal Mill Roller/Casting Shell Chemical Cement Plant

2023年3月8日 Tyre/Coal Mill Roller/Casting Shell Chemical Cement Plant Supporting of Steel Casting Support Roller Rotary Dryer Tyre for Kiln, Find Details and Price about Rotary Kiln Support Roller Adjustment Rotary Kiln Support Roller Bearing from Tyre/Coal Mill Roller/Casting Shell Chemical Cement Plant Supporting of Steel Casting Support Roller

Application of Solid Wastes in Concrete Production– A

2023年3月8日 Concrete is the backbone of infrastructural developments and most widely used construction material of every country. It mainly consists of cement, fine aggregate, coarse aggregate, and water

Hot Air Generator (HAG) Sanghavi Group

Hot Air Generator (HAG) In a process industry where excess Hot air is not available for Drying Purpose, it is essential that a Hot Air Generator is installed for generation of hot gas for the Drying of Wet Materials (eg. Raw Coal, Pond ash, Lime stone, Clay, Slag, Gypsum, Lime sludge or various additives). 1.

Cement Raw Mill in Cement Plant for Cement Raw Meal

Raw mill is mainly used for grinding cement raw meal in the cement factory production process. It is also suitable for metallurgical, chemical, electric power and other industrial mining enterprises to grind various ores and other grindable materials. Cement raw meal is a mixture of various raw materials before cement calcination.

petcoke Cement industry news from Global Cement

2023年3月8日 Turkey: Germany’s Aunde has ordered four vertical roller mills from Loesche for a new cement plant being built in Soma. The order includes one 350t/hr raw material mill, one 30t/hr coal or 27t/hr petcoke mill and two 150t/hr clinker or granulated blast furnace slag mills. The scope of delivery also includes additional components such as water