Copper Processing Plant Schematic

Copper processing Definition, History,Facts Britannica

copper processing, the extraction of copper from its ores and the preparation of copper metal or chemical compounds for use in various products. samovar In its pure form or as an alloy, copper (Cu) is one of

12.3 Primary Copper Smelting US EPA

Schematic of the Noranda process reactor. and slag processing also contribute to fugitive dust problems. Control of SO2 from smelters is commonly performed in a sulfuric

Copper MiningExtraction Process Flow Chart

2015年8月26日Copper MiningExtraction Process Flow Chart This flowchart made of machinery icons explains or expresses in simple but

Copper Process Flowsheet Example Mineral Processing

2015年10月1日A simplified schematic drawing of copper flotation flowsheet. Run-of-mine open pit ore will be crushed in a gyratory

Copper Processing Multotec

Copper processing begins with mining copper ore, which contains less than 1% of copper, and ends with sheets of 99.99% pure copper (cathodes). Copper mining generally takes place through open-pit

Copper Mining and Processing: Everything you Need to

The Copper Mining Process Once it’s located within the earth, copper ore goes through eight stages before the consumer sees it in various products that affect every day life in

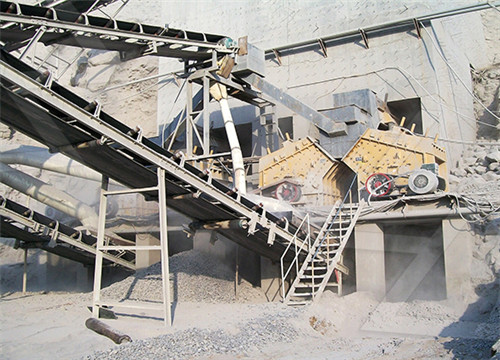

Copper Processing Equipment, Process Flow, Cases

2019年8月23日Copper ore processing According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide.

Schematic clay treatment flow sheets used in copper SX

Download scientific diagram Schematic clay treatment flow sheets used in copper SX plants from publication: A holistic approach to organic quality in copper solvent

How to Process Copper Ore: Beneficiation Methods and

2023年2月15日For example, the ore in the Nchanga processing plant in Zambia contains 4.7% copper. The copper content achieved to 50% ~ 55% through flotation by adding 500g/t of lime (pH 9 ~ 9.5), 10g/t of cresol

Achieving step change performance in copper ore processing

copper processing plant, the market value of an underperforming sorting application with a copper rejection rate of 200 kg/hr at an indicative price of US$9,500* per tonne could equate over US5M per annum in falsely rejected copper. * August 2021 Our Expertise Concentrator Optimization Comminution Control Ore Sorting Overview CB Omni Fusion

Processing routes for copper and nickel ores.

Download scientific diagram Processing routes for copper and nickel ores. j desulfurization j green metallurgy Sulfide metallurgy is the second largest emitter of SO 2 after coal-fired power

Copper Processing Equipment, Process Flow, Cases JXSC

2019年8月23日Copper ore processing. According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide. That is, sulfide ore, containing less than 10% copper oxide; oxidized ore, containing more than 30% copper oxide; mixed ore, containing 10% to 30% of copper oxide.

Integration assessment of the hybrid sulphur cycle with a copper

2021年12月1日Schematic representation of the key components of the proposed integration of the copper production plant with the HyS cycle. 1. The HyS cycle is sized to produce enough H 2 to meet the hydrocarbon (HC) fuel demand of the pyro pathway and sulphuric acid production plant.

Integration assessment of the hybrid sulphur cycle with a copper

2021年12月1日The effect of ore composition on the integration of the hybrid sulphur cycle and copper processing plant is evaluated using models developed in Aspen Plus. Process ow diagram of the developed

How to Process Copper Ore: Beneficiation Methods

2023年2月15日For example, the ore in the Nchanga processing plant in Zambia contains 4.7% copper. The copper content achieved to 50% ~ 55% through flotation by adding 500g/t of lime (pH 9 ~ 9.5), 10g/t of cresol

Integration assessment of the hybrid sulphur cycle with a

cycle and copper processing plant is evaluated using models developed in Aspen Plus. The evaluations show that Schematic diagrams of (a) copper refining process including pyrometallurgy and

ROCKLANDS COPPER PROJECT (CDU 100%) ROCKLANDS

The Rocklands Processing Plant includes a $25m purpose built native copper processing circuit that combines continuous gravity jigs, spirals and tables producing various fractions sizes of native copper. This circuit is currently under

Copper Smelting MetallurgistMineral Processing

2021年1月13日Copper Smelting Furnace Construction and Refractories Used The furnace is built in three integral sections comprising the bottom and inner furnace, the four outside walls, and the roof, providing ease of

The Evaluation of Starch-Based Flocculant on the SpringerLink

2022年3月7日In copper-molybdenum sulfide processing plants, the Cu-Mo concentrate (final product of Cu processing plant) is introduced into primary thickener (s) to increase the solid content and modify the amount of chemical reagents of the pulp used in copper flotation. The underflow of the primary thickener is the feed of the molybdenum plant [ 2 ].

COPPER Copper production TU Delft

Copper production About 80 % of primary copper production comes from low-grade or poor sulfide ores. After enrichment steps, the copper concentrates are usually treated by pyrometallurgical methods. Generally, copper extraction follows the sequence (see Figure below): 1. Beneficiation by froth flotation of ore to give copper concentrate

Preparation of Polyacrylonitrile-Based Immobilized Copper-Ion

2023年2月24日A polyacrylonitrile (PAN)-based immobilized metal-ion affinity membrane (IMAM) was prepared with a high capacity for protein adsorption. PAN was selected as the substrate due to its excellent thermal and chemical stability. The cyano groups on the PAN membrane were substituted with carboxyl groups, followed by reactions with

The process routes of primary copper production [10].

Pyrometallurgical processing is used in the processing of approximately 80% of copper. In 2014, 14.2 million metric tons of copper were produced through pyrometallurgy, while 4.1 million metric

Copper‐based nanoparticles for biopolymer‐based functional

2023年3月7日Copper, an essential element in the human body, is also necessary for the body's absorption of Fe, the structure of red blood cells, and cardiovascular health. Therefore, copper-based nanomaterials can be used directly in the industry within safe dose ranges (AlaviMoradi, 2022; Freeland-Graves et al., 2020).

Achieving step change performance in copper ore processing

copper processing plant, the market value of an underperforming sorting application with a copper rejection rate of 200 kg/hr at an indicative price of US$9,500* per tonne could equate over US5M per annum in falsely rejected copper. * August 2021 Our Expertise Concentrator Optimization Comminution Control Ore Sorting Overview CB Omni Fusion

Processing routes for copper and nickel ores.

Download scientific diagram Processing routes for copper and nickel ores. j desulfurization j green metallurgy Sulfide metallurgy is the second largest emitter of SO 2 after coal-fired power

Copper Processing Equipment, Process Flow, Cases JXSC

2019年8月23日Copper ore processing According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide. That is, sulfide ore, containing less than 10% copper oxide; oxidized ore, containing more than 30% copper oxide; mixed ore, containing 10% to 30% of copper oxide.

The process routes of primary copper production [10].

In doing so, three conceptual valorisation process schemes were formulated together with the shredding industry, each based on principally different resource recovery strategies: 1) maximising...

Integration assessment of the hybrid sulphur cycle with a copper

2021年12月1日Process flow diagram of the pyrometallurgy pathway modelled here. The blister from both the smelter and slag cleaner (Streams 12 and 14) is mixed and, after further purification in the fire...

COPPER Copper production TU Delft

Copper production About 80 % of primary copper production comes from low-grade or poor sulfide ores. After enrichment steps, the copper concentrates are usually treated by pyrometallurgical methods. Generally, copper extraction follows the sequence (see Figure below): 1. Beneficiation by froth flotation of ore to give copper concentrate

Integration assessment of the hybrid sulphur cycle with a

cycle and copper processing plant is evaluated using models developed in Aspen Plus. The evaluations show that Schematic diagrams of (a) copper refining process including pyrometallurgy and

How to Process Copper Ore: Beneficiation Methods

2023年2月15日Copper ore crushing process 1. Beneficiation methods of copper sulfide ore Copper sulfide can be divided into single copper ore, copper sulfur ore, copper-molybdenum deposit, copper nickel, carrollite

A process mineralogy approach to optimize molybdenite flotation

2020年10月1日The samples were taken from the molybdenite flotation circuit at the copper-molybdenum processing complex of Sungun. The flotation circuit of the plant consists of two 8-cell rows for the rougher flotation stage. The volume of each cell is 2.8 m 3 and of mechanical type. The cleaner stage consists of an 8-cell row, of the same type as

process flow diagram of copper ore processing Welcome to

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 99.99% pure copper called cathodes, which will ultimately be made into products for everyday use.The most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and

Copper processing Ores Britannica

The first step, mineral processing, is to liberate the copper minerals and remove waste constituents—such as alumina, limestone, pyrite, and silica—so that the copper minerals and other nonferrous minerals of

Preparation of Polyacrylonitrile-Based Immobilized Copper-Ion

2023年2月24日A polyacrylonitrile (PAN)-based immobilized metal-ion affinity membrane (IMAM) was prepared with a high capacity for protein adsorption. PAN was selected as the substrate due to its excellent thermal and chemical stability. The cyano groups on the PAN membrane were substituted with carboxyl groups, followed by reactions with

Pyrometallurgical Process an overview ScienceDirect Topics

Fig. 3.10 shows schematic diagrams of Rönnskar smelter for Cu, Pb, Zn, Ni, and PM production from both ore concentrate and e-waste. Another application for the pyrometallurgical process is Umicore’s ISR plant, which includes a Cu smelter, Pb blast furnace, PM and SM refineries, along with an H 2 SO 4 plant (Fig. 3.11).

Copper‐based nanoparticles for biopolymer‐based functional

2023年3月7日Copper, an essential element in the human body, is also necessary for the body's absorption of Fe, the structure of red blood cells, and cardiovascular health. Therefore, copper-based nanomaterials can be used directly in the industry within safe dose ranges (AlaviMoradi, 2022; Freeland-Graves et al., 2020).