Rock Cone Impact Crushers

Portable crushers Metso Outotec

Portable cone crushers can reduce any rock types. Portable impact crushers. Portable impact crushers can be divided into two different technologies, portable horizontal shaft

Types of Rock Crushers Quarry Crushing

1 Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compression-style jaw, cone,

Rock Crusher Eastman Rock Crusher

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and

Rock Crushing Equipment Rock Crushers Kemper

The type of rock crushers you need—cone, impact, jaw, gyratory, and more—largely depends on your site, the product you want to make, and how much you need to

Impact Crusher Eastman Rock Crusher

Impact crusher is a machine that uses high speed impact energy rather than pressure to reduce material size. Applications widely utilized in

The Top Rock Crusher Brands Mellott

2020年5月20日 At Mellott, we’ve been working with rock crushers for decades. We’re proud to sell and service a range of industry-leading rock crushers. From jaw crushers to

Should I Choose an Impact Rock Crusher or Cone Crusher?

Cone Crusher Applications. Cone crushers, a type of compression crusher, have less versatility than a horizontal impact crusher, but a great capability to guarantee a finished

How to Choose a Rock Crusher Sepro Aggregates

Impact vs Compression Style Rock Crushers. Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers include vertical shaft

Rock Crushers Mellott

Superior Rock Crushers For Rent With Mellott. At Mellott, we help match our clients with rock crushing equipment that is perfectly suited for your unique operational needs. To

Crushers All crusher types for your reduction

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Metso Outotec offering covers

Evaluation of size reduction process for rock aggregates in

2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratory-scale cone crusher. Based on several

Mobile crushers and screens — SRP

Mobile jaw, cone and impact crushers. We have a wide range of mobile equipment to make your job easier, no matter what you're crushing. Our range of mobile jaw crushers is one of the most comprehensive on the market, led by the international bestselling QJ341 mobile jaw crusher.

Cone Crusher an overview ScienceDirect Topics

Maintenance of the wear components in both gyratory and cone crushers is one of the major operating costs. Wear monitoring is possible using a Faro Arm (Figure 6.10), which is a portable coordinate measurement machine.Ultrasonic profiling is also used. A more advanced system using a laser scanner tool to profile the mantle and concave produces

Portable crushers Metso Outotec

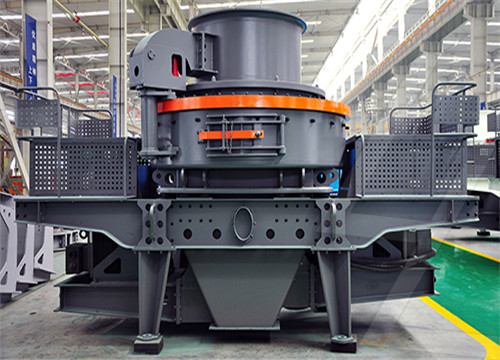

Portable cone crushers can reduce any rock types. Portable impact crushers. Portable impact crushers can be divided into two different technologies, portable horizontal shaft impact (HSI) crushers and portable vertical shaft impact (VSI) crushers. Portable HSI crushers have high reduction ratio and they are commonly used in primary, secondary

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Today, manufactures nearly 20 different cone crushers, in addition to a variety of other products, including impact, jaw and hybrid crushers. Rock crushers, like the cone crushers we'll be discussing in just a moment, generate incredible force to break raw material into smaller pieces. Once material exits the crusher, the user can

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 Horizontal shaft impact crusher (HSI) VS cone crusher. Horizontal shaft impact crusher adopts impact force created by high-speed rotating hammer to strike and throw material. Then the crushed material will hit aprons again in the crushing chamber, which is "stone on stone" crushing way.

How to Choose a Rock Crusher Sepro Aggregates

Impact vs Compression Style Rock Crushers. Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers include vertical shaft impactors or horizontal shaft impactors. Compression crushers require much less maintenance; high impact crushers undergo more wear and tear due to the material

Which Crusher Is Suitable for Your Hard Rock? Fote

2023年2月15日 Rock hardness: Mohr's Scale 6-7 Granite Crushers: Jaw crusher, impact crusher(or cone crusher)and sand maker. Crushing process: 1 Coarse crushing and fine crushing: Granite is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing, then sent to an impact crusher or cone crusher through a belt conveyor for fine

How Vertical Shaft Impact Crushers Work Mellott

2023年2月24日 By utilizing the principles of rock-on-rock crushing, they effectively reduce material size while producing minimal dust pollution and creating desirable grain shapes. To learn more about how you can use vertical shaft impact crushers to help you with your next project, reach out to the Mellott Company team of experts today at 855-554-1606.

sbmchina/sbm portable line cone crusher manufacturer

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Crushers MEKA CrushingScreening Plants

MEKA Secondary impact crushers feature a unique combination of heavy rotor design, wear material and crushing chamber design. These features result in improving capacity, product quality and in reducing operating

(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITY

2021年12月3日 Concerning cone and vertical shaft impact crushers, rock aggregate quality was investigated for products with a particle size range of 33-63 mm. As a result of full-scale crushing tests, it was

A Detailed Overview of Cone Crushers and What You

2020年6月3日 Today, manufactures nearly 20 different cone crushers, in addition to a variety of other products, including impact, jaw and hybrid crushers. Rock crushers, like the cone crushers we'll be discussing in just a moment, generate incredible force to break raw material into smaller pieces. Once material exits the crusher, the user can

Rock Crusher JawCone Rock Crushing

There are many types of rock crushers. Generally, it mainly consists of jaw crusher, cone crusher, hammer crusher, vertical shaft impact crusher, impact crusher and so on. According to the requirements of materials’

How to Choose a Rock Crusher Sepro Aggregates

Impact vs Compression Style Rock Crushers. Compression crushers include jaw crushers, cone crushers, gyratory crushers and roll crushers. Impact crushers include vertical shaft impactors or horizontal shaft impactors. Compression crushers require much less maintenance; high impact crushers undergo more wear and tear due to the material

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 Horizontal shaft impact crusher (HSI) VS cone crusher. Horizontal shaft impact crusher adopts impact force created by high-speed rotating hammer to strike and throw material. Then the crushed material will hit aprons again in the crushing chamber, which is "stone on stone" crushing way.

Which Crusher Is Suitable for Your Hard Rock? Fote

2023年2月15日 Rock hardness: Mohr's Scale 6-7 Granite Crushers: Jaw crusher, impact crusher(or cone crusher)and sand maker. Crushing process: 1 Coarse crushing and fine crushing: Granite is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing, then sent to an impact crusher or cone crusher through a belt conveyor for fine

Types of Crushing Equipment Jaw, Cone

Cone crushers, also known as conical crushers, break rock between an eccentric rotating head and a bowl. The rotating head is covered by a wear-resistant mantle. The large pieces are broken once between the two

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points)

2023年2月15日 The overall structure of the machine. From the perspective of the overall structure, the cone crusher is 1.7-2 times heavier and 2-3 times higher than the jaw crusher with the same feeding opening size. A Larger machine means

How Vertical Shaft Impact Crushers Work Mellott

2023年2月24日 By utilizing the principles of rock-on-rock crushing, they effectively reduce material size while producing minimal dust pollution and creating desirable grain shapes. To learn more about how you can use vertical shaft impact crushers to help you with your next project, reach out to the Mellott Company team of experts today at 855-554-1606.