Beneficiation Of Copper Rock Whims

Metals Free Full-Text Improving Beneficiation

2016年4月14日 In the , a new technology was developed to improve the beneficiation of copper and iron components from copper slag, by

Wet High Intensity Magnetic Separators Multotec

Separate ferromagnetic and paramagnetic particles and tramp metals with the world’s most efficient solutions. Wet High Intensity Magnetic Separators (WHIMS) from Multotec

Beneficiation an overview ScienceDirect Topics

11.5.3.1 Beneficiation. Mineral beneficiation begins with crushing and grinding of mined ore for near-complete separation of ore and gangue minerals as well as between ore

进一步探索

What does beneficiation mean? definition, meaning and audi(PDF) Overview of Mineral Processing Methods ResearchG根据热度为您推荐•反馈[PDF]

Energy and Environmental Profile of the U.S. Mining

2013年11月8日 5.1.2 Copper Beneficiation and Processing The two major processes employed in the United States to recover copper from ores are classified as either (1)

Copper-cobalt HGMS for Mineral Processing

The new floating magnetic combined technology has the advantages of short flow, low energy consumption, high grade and high yield. Some copper and cobalt mines in Africa

Pathways towards zero-emission copper mines

2020年6月28日 According to the Warren Centre, METS can be key players for finding ways to reduce both costs and emissions through innovation, a path that should also include

Flowsheet Development for Benefication of Lithium

2018年8月19日 Hard rock lithium deposits range in head grade from 0.4% Li 2 O in low grade deposits [ 4 ], to as much as 4% Li 2 O in higher grade deposits [ 5 ]. Hard rock

(PDF) An overview of the beneficiation of iron ores via

2014年3月1日 incorporates WHIMS and SLon separators at the scavenger stage. The change from gravity-based to magnetic separation improved the iron grade and recovery

dry beneficiation of copper

Dry Copper Rock Beneficiation Process Jul 16, 2012 mpl crushing, screening, grinding and washing plant play a great role in aggregate production, . Read More.

Beneficiation Of Copper Rock Whims MC World.INC

Oct 06, 2015 Although WHIMS is a well-known and proven technology across a range of commodity sectors, having been extensively used in hematite beneficiation, in the

Metals Free Full-Text Improving Beneficiation

2016年4月14日 In the , a new technology was developed to improve the beneficiation of copper and iron components from copper slag, by modifying the molten slag to promote the mineralization of valuable

Sustainable Use of Copper Resources: Beneficiation of Low

2022年4月27日 The global market has announced copper as a modern energy metal and finds its extensive utilization in the construction industry, electrical wiring, power transmission lines, alloying, anticorrosive coating, heat exchangers, refrigeration tubing, etc. Copper ore is primarily beneficiated from sulphide mineral deposits. Due to high-grade

Combined Flotation Hydrometallurgical Technology for

2020年10月28日 Abstract The possibilities of extracting valuable components and producing selective good-quality concentrates from hard-to-beneficiate crude ores are considered for the disseminated copper–nickel ores from the Norilsk district. The stated aim is achieved by a combined technology including beneficiation and hydrometallurgical

Machine learning exploration of the mobility and

1 An example of MASW recycling is the use of tailings discarded from the beneficiation process to prepare cemented paste backfill (Kasap et al., 2022), which reduces the need for inland dumping or waste disposal in rivers or seas. 2022), which reduces the need for inland dumping or waste disposal in rivers or seas. The waste rock produced

How to Process Copper Ore: Beneficiation Methods and

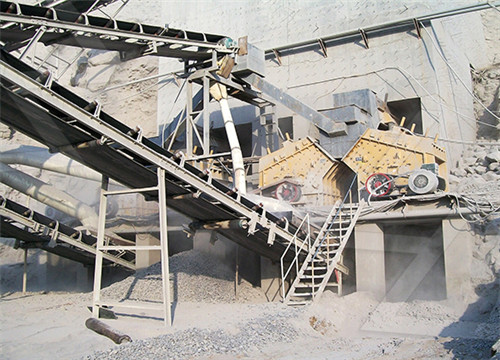

2023年2月15日 Before the beneficiation of copper ores, crushing and grinding are required. The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher. Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 0.15-0.2mm. Copper ore crushing process. 1.

Minerals Special Issue : Value of Mineralogical

2021年10月22日 Special Issue Information. Dear Colleagues, This Special Issue, focusing on the value of mineralogical monitoring for the mining and minerals industry, should include detailed investigations and characterizations of minerals and ores of the following fields for ore and process control: Lithium ores—determination of lithium contents by XRD

Copper Mining and Processing: Processing Copper Ores

1 The first steps of copper processing are the same for both ores: mining and transporting. Copper mining is usually performed using open-pit mining, in which a series of stepped benches are dug deeper and deeper into the earth over time. To remove the ore, boring machinery is used to drill holes into the hard rock, and explosives are inserted

Wet High Intensity Magnetic Separation

2017年6月4日 Beneficiation of Oxidized Taconites. WHIM is the short acronym for Wet High Intensity Magnetic Separation . At present, most U.S. iron raw materials are produced from magnetic taconites, which are

Recovery of copper from deposit of Kola Tembein,

The rock ore sample examined by XRD contained a variety of minerals, including malachite (Cu2CO3(OH) 2), quartz copper, and zinc from their oxide ores [11-14]. Leaching with acid is a common

Report to Congress: Wastes from the Extraction and

2021年6月25日 Some low-grade ore, waste rock, and tailings are used in dump or heap leaching, a process that the mining industry considers a form of beneficiation and one that involves spraying the material with acid or cyanide to leach out metals. This process is most widely practiced in the copper, silver, and gold mining segments, and the associated

Metals Free Full-Text Improving Beneficiation

2016年4月14日 In the , a new technology was developed to improve the beneficiation of copper and iron components from copper slag, by modifying the molten slag to promote the mineralization of valuable

Mineral Comminution and Separation Systems EOLSS

2020年8月25日 Keywords: Mineral beneficiation, mineral processing, coal preparation, coal cleaning, comminution, mineral liberation, gravity separation, flotation, electrostatic separation, To be more specific, let us take the example of a copper ore whose grade, or copper content, is only 1% by weight. Let us assume that the sole copper mineral species

Copper Mining and Processing: Processing Copper Ores

1 The first steps of copper processing are the same for both ores: mining and transporting. Copper mining is usually performed using open-pit mining, in which a series of stepped benches are dug deeper and deeper into the earth over time. To remove the ore, boring machinery is used to drill holes into the hard rock, and explosives are inserted

Minerals Special Issue : Value of Mineralogical

2021年10月22日 Special Issue Information. Dear Colleagues, This Special Issue, focusing on the value of mineralogical monitoring for the mining and minerals industry, should include detailed investigations and characterizations of minerals and ores of the following fields for ore and process control: Lithium ores—determination of lithium contents by XRD

Recovery of copper from deposit of Kola Tembein,

The rock ore sample examined by XRD contained a variety of minerals, including malachite (Cu2CO3(OH) 2), quartz copper, and zinc from their oxide ores [11-14]. Leaching with acid is a common

Machine learning exploration of the mobility and

1 An example of MASW recycling is the use of tailings discarded from the beneficiation process to prepare cemented paste backfill (Kasap et al., 2022), which reduces the need for inland dumping or waste disposal in rivers or seas. 2022), which reduces the need for inland dumping or waste disposal in rivers or seas. The waste rock produced

Wet High Intensity Magnetic Separation

2017年6月4日 Beneficiation of Oxidized Taconites. WHIM is the short acronym for Wet High Intensity Magnetic Separation . At present, most U.S. iron raw materials are produced from magnetic taconites, which are

Beneficiation Aspects to Improve the Quality of Bauxite

2022年11月19日 With the intention to utilize this waste rock, we herein proposed feasibility study on PLK rock using some possible beneficiation techniques. In the present study, work was conducted to improve the quality of Bauxite mining waste PLK rock using various physical beneficiation processes such as hydrocyclone, air classifier, and magnetic

A Beneficiation Study on a Low Grade Iron Ore by Gravity

2018年8月25日 In this , a sample from Tange-zagh iron mine was characterized by gravity and magnetic separation methods. The mineralogical studies showed that hematite and goethite are the main iron-bearing minerals with insignificant amounts of FeO. The results indicated that spiral separation yields higher separation efficiency than others.

Progress of Five Spodumene Beneficiation Methods

2020年7月10日 The separation methods of spodumene mainly include hand separation method, thermal cracking method, flotation method, magnetic separation method and gravity separation method. 1. Hand Separation method. In the 1950s and 1960s, manual beneficiation was one of the main beneficiation methods in the production of lithium

- Calcite Grinding Plants

- 2PGS筛分式破碎机

- 加工长石提纯长石是陶瓷

- 哪厂生产lm240m立式磨

- 钢筋混凝土破碎机视频

- 辽宁富山水泥津院立磨型号

- 手持小型破碎锤

- Zimbabwen Standard Of Mill For Copper Rock

- Equipment Crusher And Washing Iron Ore

- 遵化雷蒙磨

- Eccentric Throw Settings For Cone Crushers

- 然砂合理的分级筛余值

- Solid Gold Nonmetal After It Is Dissolved In Alcohol

- Lih Shan Mesin Ballmill Solution

- 含泥量的判定标准