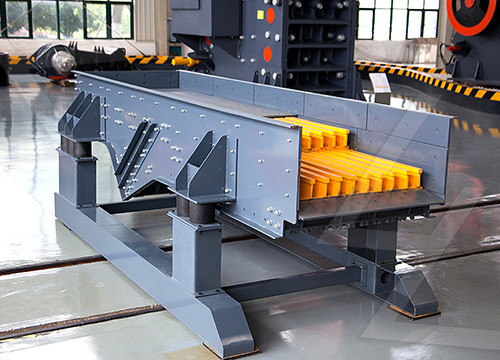

Vibrating Trash Screen Double Deck Panel

Dry Vibrating Screens for mining and industrial

Available in single, double and triple deck configurations; Available in horizontal, multi-slope and inclined versions . Additional Services . More uptime means higher profits. As a

进一步探索

Screens Brochure Dorr-Oliver Eimco PDF CatalVibrating Screen Working Principle Mineral ProcessingMAll Metso Corporation catalogs and technical brochures Dirludowici vibrating screens MiningQuarry PlantDry Vibrating Screen feed separation 根据热度为您推荐•反馈根据热度为您推荐•反馈

Mining Screens Multotec

Modular panel designs (1’ x 1’ or 2’ x 1’) optimise wear-related maintenance to cut operating costs on screen decks by up to 30%; Single or double deck configurations as your

进一步探索

DIFFERENT TYPES OF SCREENS USED FOR MINING HAggregate Screening Equipment for Mining General Kinem根据热度为您推荐•反馈

Vibratory ScreeningDewatering Equipment (1/2 in. to

High-capacity wet and dry screening using panels that are constructed from a special high temperature polyurethane material. Vibratory screening equipment is used to screen or

vibrating trash screen double deck panel electriv.pl

2019-6-28 aperture panels. Slurry is fed uniformly along the top of this back section, which acts as a vibrating drainage panel. The main deck slopes upward at 3°- 5° and is fitted

Vibrating Screen Working Principle Mineral

2015年7月26日 When the smaller rock has to be classified a vibrating screen will be used. The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined frame.

industrial use vibrating screen double deck in singapore

2022年7月6日 ined Vibrating Screen 10 in beam support frame 3 Deck vibrating screen Top Deck 2 in screen Middle Deck No screen Bottom Deck No screen ID 99886 Quote

vibrating trash screen double deck panel

vibrating trash screen double deck panel. vibrating trash screen double deck panel Panels and Plates for Vibrating Screens Vibrating screen is widely applied in industrial sectors

vibrating trash screen double deck panel

Separate construction of screen box from sifting mechanism; Single Deck, Double Deck, Triple Deck Screen Box interchangeable; Pretension framed screen panel fastened with

Vibrating Screen Panels FluidHandling Trelleborg

Trelleborg rubber screen panels are ideal for bottom deck applications where blinding is a problem. A high flexibility across the working surface of the panels can be achieved by taking advantage of properties of HA-L3 rubber compound, which is a perfect solution when screening sticky ores. Traditionally polyurethane had a better life cycle

Schematic diagram of vibrating screen and its

A double-deck linear motion vibrating screen is simulated using the DEM software LIGGGTHS. DEM is used to obtain the ore parameters in the steady state and the force on the screen decks.

Vibrating Screen Applied Vibration

2 之 A vibrating screen separates materials by size and can be used to improve and solve many product handling challenges. Typical applications include: Removing oversize material from usable product. Separating

bivi-TEC® Vibratory Screens General Kinematics

2021年11月23日 The bivi-TEC® ’s unique dual-vibratory screening process eliminates clogging and blinding of the screen openings to save downtime and increase productivity. Dual vibration from a single drive is

NewUsed Circular Vibrating Screens for Sale Mineral

2 之 Stokkermill VB-600 Circular Vibrating Screen. Model: VB-600 2-Deck Screen Screen Diameter: 24 in. Elettro Meccanica Motor 1.2 kW 480 Volt 3 phase. 60HZ. Location: British Columbia, C ID: 473664 Quote +.

The BIVITEC® Flip Flow Screen Aggregates

2 之 Banana design: Curved deck with steeper angle on feed end and lesser angle on discharge, provides increased capacity and efficiency; LL Design for bulky materials: Double the panel width and double the

Vibratory Screens General Kinematics

2020年9月13日 Vibratory Screens. A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries. From the separation of heavy ores, molten hot castings and sand, to stone products and everything in between. GK has made waves in the processing equipment industry using Two-Mass screening

On Deck: Screens for all Processes EMJ

2020年4月8日 Telsmith recently introduced a track processing solution with the 820 Track Screening Plant. This includes an 8203 TL screen, 1.4-m feed conveyor and 1.8-m under-screen conveyor, all combined to process up

Screen Aperture an overview ScienceDirect Topics

Graded coals are those from which the screen aperture at the washery lies between 3/16 and 2½ inches round hole. They include ‘doubles’, ‘nuts’, ‘singles’, ‘beans’, and ‘grains’. Small coal has no lower limit in size but has a maximum upper limit of 2 inches. Slurry and anthracite have been defined previously in 5.1.2.

Banana screens Metso Outotec

The modular design and highly available wear and spare parts combined with a low-stress designed screen body maximize uptime. Safe operation Features such as comfortable room between decks, guards and covers for moving parts, and dust and noise protection ensure that Metso Outotec vibrating screens are safe to use for operators. Easy to maintain

Double Deck Vibrating Screen-DAHAN Vibration Machinery

2022年11月3日 3 different gradings can be achieved in one operation. Price: $900.00-$4,800.00/Set. Consult now and enjoy a 10% discount. Chat Now. Send Email. Double deck 3-stage separation 95% screening efficiency. Layers: 2 layers Outlet: Outlet: Uses: Simultaneous screening of materials into 3 different sizes. Feed particle size: 0.074-10mm.

HEAVY DUTY INCLINED VIBRATING SCREENS Deister

2012年4月12日 2 and 3 deck, 8' x 20'; and on 2 deck, 8' x 24' screens. Triple vibrating mechanisms are standard on 3 deck 8' x 24' and larger units. The two shafts of the dual mechanism are each individually motor driven while the triple mechanism is driven on the feed end and discharge end shafts. Timing belts on the dual and triple mechanisms prevent

Banana Screens Vibramech

2020年10月6日 Vibramech Banana Screens Feature: Single- or double-deck configurations. 2 6 deck slopes. Integral spray bars for wet screening. A variety of wear liners suited to the abrasion/corrosion characteristics of

bivi-TEC® Vibratory Screens General Kinematics

2021年11月23日 The bivi-TEC® ’s unique dual-vibratory screening process eliminates clogging and blinding of the screen openings to save downtime and increase productivity. Dual vibration from a single drive is

Screenex Modular Screen Panels

It has to be used in conjunction with our specially designed support frame which will fit most vibrating screens. 300 square For applications using metric vibrating screens. 305 square Most popular size. 610 x 305 A

On Deck: Screens for all Processes EMJ

2020年4月8日 Telsmith recently introduced a track processing solution with the 820 Track Screening Plant. This includes an 8203 TL screen, 1.4-m feed conveyor and 1.8-m under-screen conveyor, all combined to process up

Penjelasan Mengenai Vibrating Screen Sebagai Mesin

2021年3月8日 Mesin vibrating screen yang digunakan sebagai mesin pengayak batu tentu memiliki kapasitas yang terbatas. Semakin banyak ukuran batu split yang perlu kita sortir maka semakin banyak pula tingkatan deck vibrating screen yang perlu digunakan. Tanda-tanda wire mesh screen ayakan batu yang digunakan terlalu kecil adalah ketika

- 石子处理设备

- 矿山上可以上制砂设备吗

- Mechanical Milling Operation

- 意大利电脑全动大砂锯价格

- Pf Impact Crusher Seri

- 云南破碎机球磨机企业

- Froth Crusher Copper

- 露铁矿石开采施工多少钱一吨?

- 废塑料磨粉机

- 2013 Welline Hot Selling Micro Powder Cereal Grinding Mill

- Aggregate Fine Crushing Equipment Manufacturer

- 沈阳DXN冶金设备修造厂

- Track Mounted Impact Crushing Equipment India

- 中国的花岗岩矿山开采切割设备

- Drum Lab Wet Magnetic Separator Machine