Ball Mill Motor Power Decomposed Granite New York

Converting a ball mill from overflow to grate discharge

2020年6月23日 The installed motor power for a grinding mill is a key indicator, along with the physical dimensions of the mill itself, of the capacity of the mill to process tonnes of

Ball Mill Design/Power Calculation Mineral

2015年6月19日 The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to

Ball Mill RETSCH powerful grinding and homogenization

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were

进一步探索

Lab Ball MillsLaboratory Ball Mill, 5 Kg Capacity, 10 Kg Capacity, 20 Kg C根据热度为您推荐•反馈

Custom Electric Ball Mill Motors Louis Allis

Ball mill motors are generally very large and costly to remove for service. Louis Allis has extensive experience in performing in-place refurbishment, repair, and rewind services

Ball Mill Explained saVRee

For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp (crushed ore and water) fills another 15% of the drum’s volume so

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density

17 Signs of Problems with Ball Mills: Quickly Remove

2023年2月15日 High temperature of the ball mill will affact the efficiency. 3 For every 1% increase in moisture, the output of the ball mill will be reduced by 8% -10%. 4 when the

行星式球磨仪PM100--德国RETSCH(莱驰)研磨仪粉碎仪

Download. The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8

Ball Mill JXSC Mineral

The ball mill is a well-known ore grinding machine and is widely used in mining, construction, and aggregate application. The main parts of a ball mill are motor, reducer, slow drive,

Best 30 Decomposed Granite in New York, NY with

2. Metropolitan Garden Design. Landscaping EquipmentSupplies Landscape DesignersConsultants. Website. (347) 325-1720. 22 E 88th St. New York, NY 10128. CLOSED

Design and simulation of gear box for stone crushing ball

2022年1月1日 The details of the ball mill motor are as follows. Power = 12.4 kW or 16.7 HP and the speed is 343 rpm. 3.1. Load calculations (prior to failure analysis) The ball mill can experience failure based on the maximum normal stress theory as the working loads acting in the ball mill is concentrated across the seam of the mill periphery.

Ball Mill RETSCH powerful grinding and homogenization

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest

Ceramic Ball Mill Lining BricksGrinding Media

Considering the weight of mill lining and grinding media, work out motor power required, in consultation with the mill manufacturer. To calculate the motor power required for a cylindrical type ball mill, the following formula can be applied . W = 0.04116 x D 3 x L x n x (0.6d + 0.4d1) Where: W = Required motor power in HP

Ball Mill Parameter SelectionCalculation Power,

2019年8月30日 1 Calculation of ball mill capacity. The production capacity of the ball mill is determined by the amount of material required to be ground, and it must have a certain margin when designing and selecting. There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness,

Energy-Efficient Technologies in Cement

2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are

Ball Mill at Thomas Scientific

Ball Mill found in: Gear-Drive 2-Liter Planetary Ball Mills, Mixer Mill MM200 Accessories, Laboratory Jar Mills Series 8000, 8000M Mixer/Mill, High Energy.. Horse Power 1/12 (1) Ball Mill. Compare Tool. Select up to 3 products. Refine Results. Ball Mill. 1 32 of 35. Natural Brazilian agate stone grinding balls for planetary and high

Ball mill, Ball grinding mill All industrial manufacturers

ball grinding mill L14 series. with rods horizontal stone. Rotational speed: 42 rpm 69 rpm. Rod / Ball Mills are Rubber coated and manufactured in Double and Triple Roll models. The Rolls are 120 mm diameter x 1200 mm long and powered by a 0.37 KW 220 Volt Motor with a variable speed controller. Ball /Rod

Ball Mill Price, 2023 Ball Mill Price Manufacturers

Factory Price Ball Mill for Grinding Fine Powder in Gold Ore Processing Plant. FOB Price: US$ 6800 / set. Min. Order: 1 set. Zhengzhou Hengxing Engineering Technology Co., Ltd. View larger videoimage. Contact Now. Video. High Output Cement Ball Mill Prices. FOB Price: US$ 50000-90000 / Piece.

Hardscaping 101: Decomposed Granite Gardenista

2019年8月2日 Above: A decomposed granite path runs the length of a back garden, and fast-growing fern pines (Podocarpus gracilior) create a privacy screen inside the back fence. Photograph by Mimi Giboin. See more of this garden at BeforeAfter: A 1940s-Suburban House Grows Up Gracefully in Mill Valley, CA. Decomposed granite is like gravel, but

Decomposed Granite Low Quarry Direct Prices

Blue Decomposed Granite 3/8" Minus TruckLoad Per Ton. A Central Valley California quarry, shipping bulk throughout Central and Northern California and Reno Sparks Nevada metro areas. SuperEarth-sack delivery

Converting a ball mill from overflow to grate discharge

2020年6月23日 The installed motor power for a grinding mill is a key indicator, along with the physical dimensions of the mill itself, of the capacity of the mill to process tonnes of ore. The potential to make full use of the available power in a ball mill through conversion from overflow to grate discharge often results in the mill being able to

Rear view of the ball mill showing the electric motor, the

Another possibility for monitoring the mill filling level is the measurement of the motor: power draw [38], torque [39] and other signals from the motor control units [18,24,40]. Since the engine

Ball Mill Design/Power Calculation Mineral

2015年6月19日 The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution. The following shows how

Mining Grinding and Processing WEG

Grinding and processing. WEG offers the most reliable and efficient solutions for milling plants for ferrous and non-ferrous products with their experience of mill drive systems. In the heart of a processing plant, the ball and SAG mills must be driven by solutions that adapt to the characteristics of the minerals in line with the whole process.

Custom Electric Ball Mill Motors Louis Allis

Ball mill motors are generally very large and costly to remove for service. Louis Allis has extensive experience in performing in-place refurbishment, repair, and rewind services on ball mill motors regardless of the motor OEM. Our manufacturing facility is ISO 9001:2015 certified. Motors are manufactured, remanufactured, or repaired to a range

ES580L series application in ball mill cumark.cn

The ball mill motor has a large power and is one of the largest power-consuming devices in the ceramic industry. The original power frequency start control operation scheme has many drawbacks. Start no reversal, low speed and large torque output, effectively guarantee the ball mill control system process; 2.efficient power-saving capacity

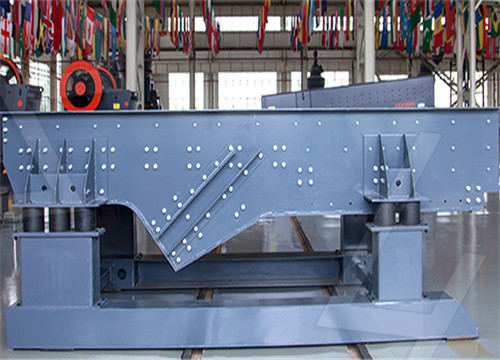

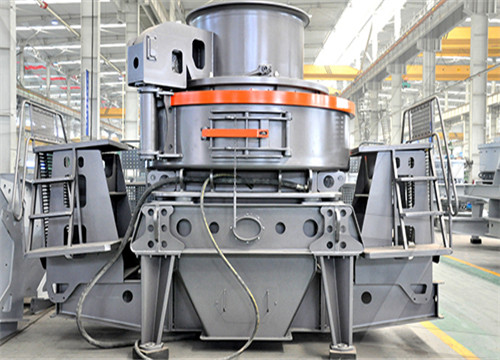

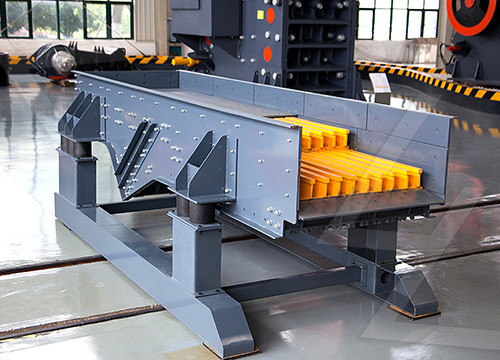

Vibratory Ball Mill Industrial Vibration Ball Mill For Sale

Capacity: 0.001-16 t/h. Material: limestone, granite, iron ore, ceramic, chemicals, etc. The ZM series vibratory ball mill, also known as vibration ball mill, is a new type of energy-saving ball mill grinder. It is mostly used for processing fine powder and ultra-fine powder, and it can realize both dry grinding and wet grinding.

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density

Energy-Efficient Technologies in Cement

2016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials. The overall grinding circuit efficiency and stability are

Mengenal mesin Ball Mill mesin penghalus

2023年3月6日 Dengan berputarnya badan barel ini maka steel ball ikut bergerak disebabkan gaya sentifugal yag terus terjatuh dan mengakibatkan bahan keras yang ada didalam mesin tergiling. Gerakan dari bola

- Video Files On Mining Engineering

- Ac Motor For Stone Mining Mill

- 高压旋喷桩工作量计算方法

- 移动破碎 招标

- 河南矿山设备厂

- 德国进口破碎站

- Sand Castle Builder

- Stone Crusher For Russia Cost And Sale

- 雷蒙磨机销售点

- Fault Code Jaw Crusher C12 Extec

- Indian Pulverizer Manufacturer Indore

- Cheap Wash Plants For Sale

- Stone Crusher Plant For Sale

- 20目T130X加强超细磨粉机

- Stone Quarrying Business In Nigeria