Fundamental Of Mobile Crusher

Mobile Crusher Eastman Rock Crusher

Mobile crusher is often referred to as ‘mobile crushing plant’, is a wheel or crawler rock crushing plant that innovatively designed for unfixed

Mobile Crushers Mineral Processing

2015年12月23日 Semi mobile crushers are still operated at the mining face but are not moved as often as the mobile crusher.. A movable crusher is

A fundamental model of a cone crusher Semantic Scholar

Semantic Scholar extracted view of "A fundamental model of a cone crusher" by C. A. Briggs. and aggregate industry for fragmentation and production of rock materials.

Henan Mining Machinery and Equipment Manufacturer

2003 w VOL. 49 NO.152 Development of Mobile Impact Crusher BR480RG — 1 — 1. Introduction 1-1 Market trends The fundamental need of the market for mobile crushers

cone crusher fundamental

Fundamental Cone Crusher fundamental of mobile crusher Crusher Wikipedia. With the rapid development of mining technology, the cone crusher can be divided into four

mill/sbm fundamental model of cone crusher.md at main

Contribute to crush2022/mill development by creating an account on GitHub.

Fundamental Of Mobile Crusher

Professional Mobile Crusher Used In Mining Manufacturer With 30 Years Experience. 2022-7-15Wide Application of Mobile Crusher Mobile crusher is a kind of movable crushing

Mobile Crusher Fundamental

2022年1月15日 Mobile Crusher And Screener Market Demand, Growth, SWOT Sep 01, 2021 The Overall Mobile Crusher And Screener Market by Market Research Intellect

What is a Mobile Crusher, and how to Buy a Mobile Crusher?

2021年4月25日 Mobile Crusher are truck-mounted portable rock ore crushing machines that produce on-site aggregates. Mobile crushers, also known as stone crushers, are

A fundamental model of an industrial-scale jaw crusher

2017年5月1日 Fundamental models will in general require fitting parameters to correspond well to observed data. The most important part of fundamental modelling is the appearance of the results being similar to that of measured data. 6. Conclusions. In this study, a fundamental model of a jaw crusher has been developed.

Global Market Study On Mobile Crushers

The Global Mobile Crushers And Screeners Market was valued at US$ 2,878.3 Million in 2022 and is projected to expand steadily at a CAGR of 7.8 % to reach a market valuation of close to US$ 6,806.1 Million by 2033.

All crusher types for your reduction needs

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a

(PDF) Design of Impact stone crusher machine

2019年5月31日 The main objective is to design impact stone crusher. Impact stone crusher involves the use of impact rather than pressure to crush materials. The material is held within a cage, with openings of

The 10 Best Mobile Crusher Manufacturers Globally

2 之 Mobile crusher accessible offer quick and smooth mobility on the site, allowing precision and flexibility. Mobile Cone Crusher provides 200-500 horsepower and offers versatility. This reputable manufacturer delivers on its promise with a capability of producing 300-500 tons per hour. Moreover, HSI plants come in open or closed circuit

Types of Crushers: What You Need to Know Machinery

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits.

A fundamental model of a cone crusher 百度学术

A formal approach to the modelling of a cone crusher is presented. The emphasis is on predicting the final output of a cone crusher using only the physical mechanisms which are occurring. Each of these mechanisms are clearly identified and mathematical formulations are provided for each. 关键词:. Crushing machinery -- Design and

Crushing Plant Design and Layout

1 Considerations of stone crusher plant design. The basic purpose of crushing ore is to achieve a certain particle size requirement for ore, raw materials or fuel. In ore dressing, the purpose of crushing ore is: (1)

Comparative Analysis on the Performance of Non

the material in the crusher based on the primary crusher settings. An analysis of the muckpile to determine the size distribution is known as fragmentation size analysis. The split desktop analyser software Version 3.0 was used for the analysis. The muck pile image to be analysed was opened on the software using the ‘open’ tool from the dropped

sbm/sbm rolling crusher fundamentals.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Mobile Crushers and Screeners Market Size Forecast to

2023年3月4日 The global mobile crushers and screeners market size was valued at $2,467.5 million in 2020 and is projected to reach $4,354.9 million by 2030, growing at a CAGR of 5.7% from 2020 to 2030. Mobile crushers and screeners are used in mining operations, recycling, and aggregates production. Mobile crushers used to break stone

Global Market Study On Mobile Crushers

The Global Mobile Crushers And Screeners Market was valued at US$ 2,878.3 Million in 2022 and is projected to expand steadily at a CAGR of 7.8 % to reach a market valuation of close to US$ 6,806.1 Million by 2033.

A fundamental model of a cone crusher Semantic Scholar

Semantic Scholar extracted view of "A fundamental model of a cone crusher" by C. A. Briggs. and aggregate industry for fragmentation and production of rock materials. Cone crusher control systems are widely used for machine protection, wear Expand. 35. PDF. Save. Alert. What is required from DEM simulations to model breakage in mills.

Mobile Crusher For Sale Mobile Crushing Plant With

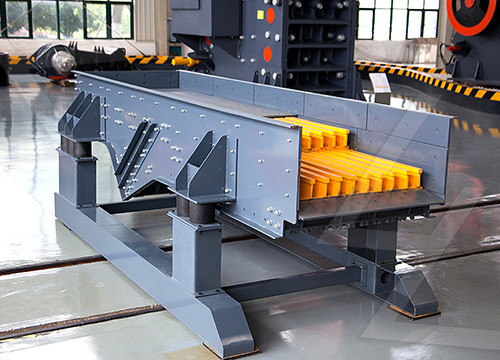

Mobile Crusher. Mobile crusher is also called mobile crushing plant. It can be equipped with a feeder, a crushing unit, a conveyor belt, and screening equipment. The combination of units is flexible. All components are constructed on the body frame as a whole. Mobile crusher is often utilized in the aggregate, mining, industry, demolition

Mobile Crushing Plant Mobile Crusher Plant

CONSTMACH “mobile jaw and impact crushers” are used for crushing wide range of rocks from limestone to basalt. Presence of primary jaw crusher enables to crush big and hard rocks. On the other hand, thanks to the

Comparative Analysis on the Performance of Non

the material in the crusher based on the primary crusher settings. An analysis of the muckpile to determine the size distribution is known as fragmentation size analysis. The split desktop analyser software Version 3.0 was used for the analysis. The muck pile image to be analysed was opened on the software using the ‘open’ tool from the dropped

Jaw Crushers McLanahan

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double

A fundamental model of a cone crusher University of

2022年9月8日 A formal approach to the modelling of a cone crusher is presented. The emphasis is on predicting the final output of a cone crusher using only the physical mechanisms which are occurring. Each of these mechanisms are clearly identified and mathematical formulations are provided for each. Rock breakage characterisation is

Henan Mining Machinery and Equipment Manufacturer

2003 w VOL. 49 NO.152 Development of Mobile Impact Crusher BR480RG — 1 — 1. Introduction 1-1 Market trends The fundamental need of the market for mobile crushers fundamental principles of jaw crusher crusher for sale Download (3054kB) Murdoch Resech Repository crusher selection criteria discussed in Section 9.1.1.

What Are the Differences Between The 7 Types of Crushers?

2023年2月15日 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.