Alumina Ore Flotation Cell Ball Mill For Alumina Plant

Flotation of Alumina on the Surface of the Electrolyte in an

2020年5月4日 Abstract and Figures. A model of flotation was developed and applied to alumina in the aluminum electrolysis cell. The conditions of flotation for alumina on the

Alumina balls, alumina grinding ball, mill linings

2015年2月3日 Alumina Ball. Our alumina ball is made of α alumina (α aluminium oxide, the most thermodynamically stable form) by cool isostatic pressing and fired at a very high temperature in the tunnel kiln. Our

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation,

alumina ball mill machine cylinder flotation cell mill

Ball Mills. Ball Mills Capacity 0.2 90 T/H Advantages Designed for long service life minimum maintenance can grind and homogenize mineral ores down to the nano range a large

7 factors affecting the flotation effect of flotation machine

2023年3月9日 For coarse-grained monomer minerals, the grinding fineness must also be smaller than the upper limit of mineral flotation, for example, the upper limit of flotation of

Mineral Processing, Equipment Manufacturers, Ball Mills,

Different Factors on Flotation Efficiency of Chalcopyrite Copper Ore and Pyrite 2023-03-08; What Are Differences in Beneficiation Process between Aphanitic and Fine Flake

sbmchina/sbm small iron processing plant.md at main

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Nigeria Spodumene Lepidolite 500tpd Flotation Lithium

Nigeria Spodumene Lepidolite 500tpd Flotation Lithium Cell Li2o Processing Plant,Encontre detalhes sobre Lithium Cell, Flotation Cell a partir de Nigeria Spodumene Lepidolite

Alumina Ball Mill Machine Cylinder Flotation Cell Mill

Quality Mining Ball MillCeramic Ball Mill Manufacturer Ball Mill For Cement Suppliers, all Quality Ball Mill For . Yuhui high quality cement grinding ball mill with best price

Effect of mill type on the size reduction and phase

2015年9月29日 Single ball milling (mpl) was carried out using a Retsch MM200 vibratory single ball mill. An 11 ml stainless steel milling jar with a 12 mm diameter spherical stainless steel ball is used for single ball milling for durations of up to 1200 min at a milling frequency of 30 Hz.In single ball milling (Fig. 2 a), short duration collisions dominate and the energy

Bull. Mater. Sci., Vol. 19, No. 6, December 1996, pp. 905

2019年4月9日 The first alumina plant set up in 1894 had a capacity of 4 tonnes per year (tpy). Since then the plant capacity has been steadily increasing, attaining the level of 1-1.5 million tpy in 1980. The present day plant capacity is invariably around 1-2 million tpy. The

China Zibo Factory Supply Irregular Shaped Convex

2 之 4.Three Own-designed production lines, the ball mils are own produced. We supply a wide range of pre-engineered alumina ceramic tiles tailor-made to suit any type of application such as short and long radius small and large bore pipes and pipe bends, square to round transitions, cones etc.

Production of green, low-cost and high-performance

1.Introduction. Copper, as one of the most common metals, is mainly produced from copper ore concentrates by a pyrometallurgical process [1].In this process, a FeO-SiO 2-based slag is also produced as a by-product [1], [2].Generally, 2.2 ∼ 3.0 tonnes of copper slag is generated for every tonne of copper produced [1], [3].Over the past few years, the annual

Quantifying rheological and fine particle attachment

Graphical abstract. Effect of fine particles of alumina (2% v/v) and silica (3% v/v) on the recovery of coarse quartz in the size range 600–850 μm. Small decreases in particle contact angle, due to the attachment fine hydrophilic particles, can decrease the contact angle below a critical value depressing flotation.. Download : Download full-size image

Miniplant Project to Evaluate Alumina Recovery Processes

2019年3月11日 The miniplant operation is designed to produce 25 pounds of alumina per hour. A modular design will allow easy switching from one processing system to another. For ease of operation, the testing program was sited at the Bureau’s Boulder City facility where adequate floor space and laboratories are available.

Project Report on activated alumina balls Manufacturing

Project Report on activated alumina balls Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Manufacturing Plant, Profile, Business Plan, Industry Trends, Market Research, Survey, Investment Opportunities, Cost And Revenue, Plant Economic. ACTIVATED ALUMINA BALLS [CODE NO.3220] Activated alumina balls are highly

Alumina ceramic lined ball mills chinagrindingmill.net

Alumina ceramic lined ball mills. Post at: 28 May 2012 Gulin supply Mining and construction equipment for mineral handling. The crushing, screening, washing, grinding equipment in stationary, portable, tracked type is available. Also turnkey projects of crushing plant, powder plant.

sbmchina/sbm raw bauxite sample unit machinery.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

alumina plant ball mill maintenance annual contractors

alumina ball Companies for alumina ball Manufacturers . power plant pipeline wear-resistant ceramic liners and pipes, ball mill etc; The wear-resistant Global alumina ball buyers find suppliers here every day. ? More detailed suriname bauxite ball mill, bauxite mineral,bauxite information . aluminum ore crusher ball mill maintenance. iron ore

Production of green, low-cost and high-performance

1.Introduction. Copper, as one of the most common metals, is mainly produced from copper ore concentrates by a pyrometallurgical process [1].In this process, a FeO-SiO 2-based slag is also produced as a by-product [1], [2].Generally, 2.2 ∼ 3.0 tonnes of copper slag is generated for every tonne of copper produced [1], [3].Over the past few years, the annual

Materials Free Full-Text Contribution to Understanding

2022年2月7日 Recently, much attention has been paid to the reuse of bauxite residues from alumina production, also known as red mud, in the cement industry. Red mud bears the potential to improve concrete properties due to its favourable chemical composition and particle size. In this work, the synergy between locally available red mud and common

Laboratory Column flotation studies for reduction of

2014年10月28日 A typical iron ore washing plant for treating iron ore fines (<10 mm) consist of sizing of the ore by dry / wet screening, washing, classification by screw classifiers followed by single or multi-stage hydrocycloning of screw classifiers overflow. The underflow of the hydrocyclones forms the concentrate which is suitable for pellets making.

Alumina Balls and Cylinders Grinding Media

2019年4月9日 The unique microstructures of FOX Alumina Balls result in hard, chemically inert grinding balls, that are corrosion resistant, non toxic, non magnetic, and non porous. This alumina grinding media possesses

Quantifying rheological and fine particle attachment

Graphical abstract. Effect of fine particles of alumina (2% v/v) and silica (3% v/v) on the recovery of coarse quartz in the size range 600–850 μm. Small decreases in particle contact angle, due to the attachment fine hydrophilic particles, can decrease the contact angle below a critical value depressing flotation.. Download : Download full-size image

sbmchina/sbm raw bauxite sample unit machinery.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Simple Ore Extraction: Choose A Wholesale alumina

Stamp mills are less sophisticated than ball mills, but affordable and effective for basic rock crushing. And they can deal with larger rock quantities as well. Whatever mill style is needed, Alibaba's wholesale catalog can help you out. So order a new alumina ceramic ball mill and make ore separation simple.

China Zibo Factory Supply Irregular Shaped Convex

2 之 4.Three Own-designed production lines, the ball mils are own produced. We supply a wide range of pre-engineered alumina ceramic tiles tailor-made to suit any type of application such as short and long radius small and large bore pipes and pipe bends, square to round transitions, cones etc.

alumina process of flotation 」

Froth flotation grinding mills,Copper ore ball mill process Froth flotation was the. Inquire Now; A review of pretreatment of diasporic bauxite ores by . Request PDFA review of pretreatment of diasporic bauxite ores by flotation separationThe Bayer process is a conventional method for refining bauxite in the production of alumina. The Al/Si

alumina ore beneficiation plants

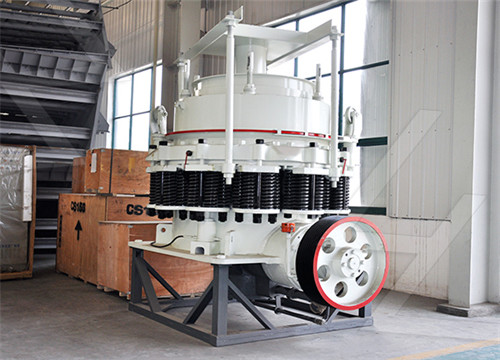

Flotation Machine. 5X Vibrating Screen. MTW-Series European Tech. Grinding Mill. Ball Mill. Jaw Crusher. Belt Conveyor. CS Cone Crusher. VM Vertical Grinding Mill. 2020-06-24T11:06:32+00:00 Aluminum Manufacturing IFC. alumina plant In some cases, ore is upgraded by beneficiation (washing, size classification, and separation of liquids and