Screens To Remove Water From Ore

Ore, RockAggregate Screening (Complete

2016年6月20日 A-Z Guide to Screening Ore, RockAggregate. Due to the surface tension of water the finest particles adher to the surface of

Liquid Stream Fundamentals: Screening Water

2 之 Fine screens have more elaborate cleaning mechanisms compared with coarse screens since attached organic material is more difficult to remove from smaller

进一步探索

Wastewater Screening Calculations SpreadsheetTypes of Screening in Wastewater Treatment AOS根据热度为您推荐•反馈

Bar Screens for WaterWastewater Treatment Hydro

How the Bar Screen Works. Bar screens typically work on a conveyor system. This allows the screen to pick up solids while allowing water to pass through. As solids accumulate

Dewatering Screens Wet Screens Derrick Machine

A waste power boiler uses a wet scrubber to remove ash from the boiler system. The water containing unburned carbon (char) and sand with grit is then pumped at a rate of

Screens To Remove Water From Ore gordonvanveelen

Aug 05, 2016 Screens To Remove Water From Ore screens to remove water from ore. Iron Ore Processing for the Blast Furnace. Water is added at this point to transport it (94

Is There a Porch Screen Fabric That Will Repel

2022年8月2日 Mesh screens are graded according to the number of holes per square inch. A mesh screen with a low number has a coarse, open weave. A high number indicates a very fine mesh with small holes.

Screens To Remove Water From Ore jasnost

Screens To Remove Water From Ore; Gold extraction Wikipedia. The solubility of gold in a water and cyanide solution was discovered in 1783 by Carl Wilhelm Scheele, but it was

screens to remove water from ore

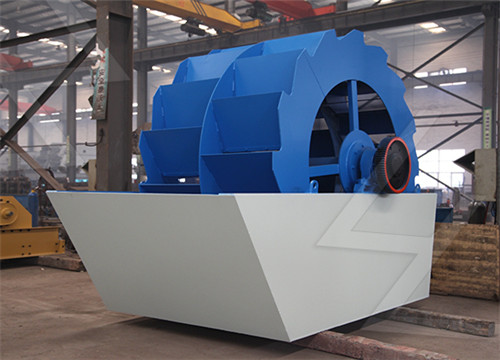

screens to remove water from oreGrinding Mill China screens to remove water from ore Washing is the use of water washing or mechanical scrubbing additional Iron

screens to remove water from ore brukdar.pl

2022年5月26日 How to Remove Hard Water Stains from Toilets Know More. Sep 08, 2018 0183 32 STEPS ON HOW TO REMOVE HARD WATER STAINS FROM TOILETS

Ore, RockAggregate Screening (Complete

2016年6月20日 A-Z Guide to Screening Ore, RockAggregate. Due to the surface tension of water the finest particles adher to the surface of the larger particles and are carried to the wrong fractions. Acceleration

Environmental Protection Agency Wastewater

2012年9月26日 various types of coarse screens. Fine Screens Fine screens are typically used to remove material that may create operation and maintenance problems in downstream processes, particularly in systems that lack primary treatment. Typical opening sizes for fine screens are 1.5 to 6 mm (0.06 to 0.25 in). Very fine screens with openings

Vibratory ScreeningDewatering Equipment (1/2 in. to

They are also used to dewater or dry waste material before disposal. This type of high frequency vibrating equipment only drives the rectangular polyurethane screen panel, while the frame remains fixed. High capacity screening equipment can screen or classify material ranging in sizes from 1/8 inch (3mm) down to 325 mesh.

Preliminary Treatment of Waste Water

2017年3月24日 The objective of screens is to remove large floating material and coarse solids from wastewater. It may consist of parallel bars, wires or grating placed across the flow inclined at 30o-60o. It achieves

How To Remove Water From Ears 15 Easy Way

2020年11月30日 Dip a washcloth in a bowl of hot water, remember that the water should not be scalding. Let the washcloth wet then wring out the excess water from it. Lie down on your affected ear side. Place the hot

screens to remove water from ore piekarnia-domchleba.pl

Fine screens are typically used to remove material that may create operation and maintenance problems in downstream processes, particularly in systems that lack primary treatment. Typical opening sizes for fine screens are 1.5 to 6 mm (0.06 to 0.25 in). Very fine screens with openings of 0.2 to 1.5 mm (0.01 to 0.06 in) placed after coarse or

screens to remove water from ore

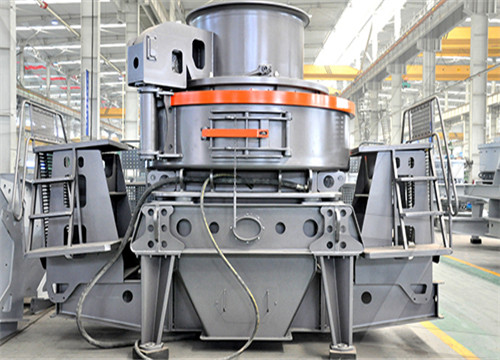

Spray the screen down to get all the baking soda off. Rinse with warm water. Screens To Remove Water From Ore. Screens to remove water from oreOur company is a large-scale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research production and marketing.

screens to remove water from ore

2020-12-25T18:12:13+00:00 screens to remove water from ore. Screens To Remove Water From Ore Screens to remove water from ore,Our company is a largescale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing We are concentrating on producing and

Dewatering Screens Wet Screens Derrick Machine

A waste power boiler uses a wet scrubber to remove ash from the boiler system. The water containing unburned carbon (char) and sand with grit is then pumped at a rate of 2,300 GPM to vibratory dewatering screens. The urethane screen panels remove the char and most of the sand and grit from the water. These solids are then moved by conveyor

Applied Sciences Free Full-Text A Study on the Dynamic

Various vibrating screens are often applied in various industries, e.g., mining, agriculture, and others. The complex shapes of the screen trajectories in the oscillating motion strongly affect the best processing properties of such machines. One of the possible methods for obtaining such complex shapes is the application of double-frequency vibrators on such

Ore, RockAggregate Screening (Complete

2016年6月20日 A-Z Guide to Screening Ore, RockAggregate. Due to the surface tension of water the finest particles adher to the surface of the larger particles and are carried to the wrong fractions. Acceleration

The MBR Site MBR Screening Part 1: MBR screen designs

2015年9月28日 3 mm, preferably 2 mm. flat sheet/panel MBRs. Ultra-fine screening. 2 mm, preferably ≤1 mm. hollow fibre MBRs. Screens come in a number of different designs, each suitable for a particular purpose. In summary, the most common screen designs are as follows: Spiral-screw gravity-flow stationary screens. Through-flow, escalator, step screens.

Environmental Protection Agency Wastewater

2012年9月26日 various types of coarse screens. Fine Screens Fine screens are typically used to remove material that may create operation and maintenance problems in downstream processes, particularly in systems that lack primary treatment. Typical opening sizes for fine screens are 1.5 to 6 mm (0.06 to 0.25 in). Very fine screens with openings

The rotary drum screen: compact, reliable and

1 The rotary drum screen ensures a fine screening based on the selected mesh size. These sizes range from 0.25 mm to 2.5 mm and the most common are 1 mm. In addition, there are two types of rotary drum

Wastewater Treatment Screen Manufacturer and Supplier

To carry out screening, most water treatment plants use wastewater treatment screens. These screens are specially designed to remove material/solids efficiently. Commonly, the screens used in wastewater treatment are categorized into; Coarse Screens These remove rags, large solids, and debris. Typically, they have openings measuring not

Water Screen Maintenance Improves Cooling Tower

2023年3月7日 The screens filter out large debris, in turn, protecting pumps, heat exchangers and downstream systems by filtering out debris that finds its way into the cold-water basin. The efficiency of cooling towers is critical to maintaining production given the large-scale heat transfer necessary to provide cooling water to the plant.

Combined Sewer Overflow Technology Fact Sheet:

2012年9月26日 and fine screens generally have rounded or slotted openings of 0.3 to 1.3 centimeters (0.1 to 0.5 inch) clear space. Coarse Screens Course screens are constructed of parallel vertical bars and are often referred to as bar racks or bar screens. In CSO control and treatment facilities, coarse screens are usually the first unit of equipment in the

How To Remove Water From Ears 15 Easy Way

2020年11月30日 Dip a washcloth in a bowl of hot water, remember that the water should not be scalding. Let the washcloth wet then wring out the excess water from it. Lie down on your affected ear side. Place the hot

screens to remove water from ore piekarnia-domchleba.pl

Fine screens are typically used to remove material that may create operation and maintenance problems in downstream processes, particularly in systems that lack primary treatment. Typical opening sizes for fine screens are 1.5 to 6 mm (0.06 to 0.25 in). Very fine screens with openings of 0.2 to 1.5 mm (0.01 to 0.06 in) placed after coarse or

screens to remove water from ore

Spray the screen down to get all the baking soda off. Rinse with warm water. Screens To Remove Water From Ore. Screens to remove water from oreOur company is a large-scale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research production and marketing.