Process Of Dolomite Using Machine

sbm/sbm process of dolomite using machine.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Production process of dolomite-based facing building

2020年11月18日 A formulation of laboratory GDS samples based on activated caustic dolomite has been developed. It has been found that the strength of the obtained GDS

A review on dolomite: Genesis, application and

2013年4月1日 Characterisation studies of dolomite fines (<2 mm) sample generated from a dolomite processing plant of Odisha were carried out,

How to process dolomite rock and what is it used for?

2023年2月15日 Process 1: Crushing and screening dolomite rock. 1 Coarse crushing: First, large dolomite rock is sent to a jaw crusher for coarse crushing. 2 Fine crushing: Then

Dolomite Milling Machines-Fine And Ultrafine Powder

2021年9月9日 The processing flow of dolomite powder is divided into 4 parts, namely crushing, grinding, collecting and packaging. 1. Crushing part. First, the large pieces of

PRACTICES OF DOLOMITE APPLICATION IN THE

2018年6月1日 The analysis results of the dolomite structure using the X-ray phase analysis method, shown in Figure-1, revealed the availability of the main components of the rocks,

Process Of Dolomite Using Machine MC World.INC

process of dolomite using machine lindadekeuster. Lime and Calcined Dolomite for Use in Steel Plant,Dec 23, 2014 Lime and Calcined Dolomite for Use in Steel Plant Lime is a

process of dolomite using machine

2019-12-15T02:12:31+00:00 Process for Producing Dolomite Powder by feng li The main production equipment using dolomite mechanical grinding, crusher, sand making

process of dolomite using machine machine bangladesh

The inverter control stacking system is adopted for stable and safe operation. From feeding to stacking, the entire china brick making machine production process is completed by a

How to Process Dolomite: Dolomite Crushing And

2023年1月13日 Stage I: crushing of raw dolomite. Bulk dolomite materials are crushed by the crusher to the feed fineness (15mm-50mm) that can enter the grinding mill. Stage II:

Performance of Dolomite Calcination in a Bench

2018年1月1日 This research is aimed to study the performance of dolomite calcination in a bench-scale rotary kiln with 500 gram of feed. The effect of various parameters, including temperatures, feed rate

Production process of dolomite-based facing building

2020年11月18日 A formulation of laboratory GDS samples based on activated caustic dolomite has been developed. It has been found that the strength of the obtained GDS samples is much higher (up to 4-8 MPa

Thermal behavior of natural dolomite SpringerLink

2014年12月3日 The thermodynamic analysis of the thermal decomposition reaction of carbonates showed that the temperatures of thermal stability of dolomite and magnesium carbonate are very similar. Kinetics of isothermal and non-isothermal decompositions of natural dolomite in air atmosphere were investigated. Under the examined conditions,

Study on regulators of purifying magnesite ore

2021年8月20日 Feng Qigui et al. 12 invented a new flotation process using #2 oil, water glass, and oleic acid to obtain a better separation effect by adjusting the dosage of this combination and combining it

Improving flotation separation of apatite from dolomite

2020年9月1日 PAMS (poly (acrylic acid-co-maleic acid) sodium salt), a commercially available polymer, has been widely utilized as a complexing agent in the complexation-ultrafiltration process owing to their non-toxic, non-nitrogenous, non-phosphorus and biodegradable features (Jiao et al., 2013).As a copolymer of maleic acid and acrylic acid,

(PDF) Flotation Separation of Dolomite from Fluorapatite

2022年2月10日 The flotation results demonstrate that NSFC showed a higher affinity towards dolomite instead of bastnaesite, and rare earth element can be effectively recovered using NSFC as depressant in

How to Process Dolomite: Dolomite Crushing And

2023年1月13日 Stage I: crushing of raw dolomite. Bulk dolomite materials are crushed by the crusher to the feed fineness (15mm-50mm) that can enter the grinding mill. Stage II: grinding of dolomite particles. The crushed dolomite small pieces are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill by the feeder

Integrated Diagenetic-Depositional Facies (IDDF)

The uniqueness outlined in this stone lies in how the process of the IDDF classification is guided using several genetic and analytic criteria: (1) Distinctive RCA porosity to permeability cross-plots and transforms (Fig. 3), (2) Typical well-log values, cross-plots and signatures, (3) Certain depositional lithofacies based on core descriptions

Machines Free Full-Text Parametric Optimization of

2022年7月28日 In the present study, a comparison of two widely used optimization approaches for fused deposition modeling (FDM), that is, Taguchi method in contrast with response surface method (RSM), was investigated. Four operating parameters, namely extrusion temperature, layer thickness, raster width, print speed, and their interaction

Process Of Dolomite Using Machine MC World.INC

process of dolomite using machine lindadekeuster. Lime and Calcined Dolomite for Use in Steel Plant,Dec 23, 2014 Lime and Calcined Dolomite for Use in Steel Plant Lime is a versatile compound,The complete process of calcination and conversion back to calcium carbonate is known as lime cycle,It is commonly used in pig casting machines where a

Dolomitization mineralogy Britannica

dolomitization, process by which limestone is altered into dolomite; when limestone comes into contact with magnesium-rich water, the mineral dolomite, calcium and magnesium carbonate, CaMg(CO3)2, replaces the calcite (calcium carbonate, CaCO3) in the rock, volume for volume. Dolomitization involves recrystallization on a large scale. The

Thermal behavior of natural dolomite SpringerLink

2014年12月3日 The thermodynamic analysis of the thermal decomposition reaction of carbonates showed that the temperatures of thermal stability of dolomite and magnesium carbonate are very similar. Kinetics of isothermal and non-isothermal decompositions of natural dolomite in air atmosphere were investigated. Under the examined conditions,

Evolution of hydration process of cement-based material

2022年2月27日 Abstract. This study focused on the evolution of hydration process of cement-based material containing high volume of dolomite powder. The hydration products, microstructure, morphology and mechanical property of cement-based material blended with dolomite powder were investigated by means of isothermal calorimetry, X-ray

Dolomite Milling Machines-Fine And Ultrafine Powder

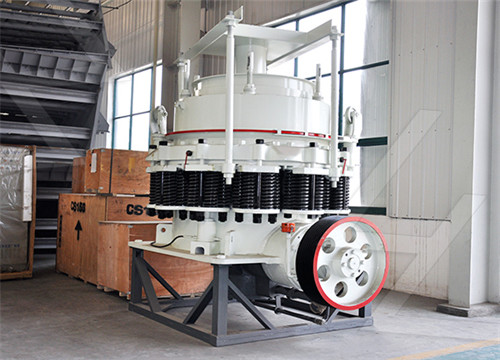

2021年9月9日 The processing flow of dolomite powder is divided into 4 parts, namely crushing, grinding, collecting and packaging. 1. Crushing part. First, the large pieces of dolomite mined are initially crushed by jaw crushers or hammer crushers. If necessary, it can be sent to the cone crusher for further medium and fine crushing.

Dolomite and dolomitization model- a short

2018年7月13日 On the basis of the mode of formation, dolomites can broadly be divided into two groups: primary dolomite and secondary dolomite. 2 Primary dolomite precipitate directly from aqueous solution,

How to Process Dolomite: Dolomite Crushing And

2023年1月13日 Dolomite is an important raw material for machine-made sand production and dolomite powder with different fineness also has wide applications. present, the common dolomite powder in the market mainly includes 200mesh, 325mesh, 425mesh, 800mesh and 1250mesh. To process dolomite into powder with suitable fineness, we

Preparation and Characterization of Malaysian Dolomites

2012年12月18日 Three types of local Malaysian dolomites were characterized to investigate their suitability for use as tar-cracking catalysts in the biomass gasification process. The dolomites were calcined to examine the effect of the calcination process on dolomite’s catalytic activity and properties. The modifications undergone by

5 Facts About Dolomite You Might Be Confused Fote

2023年2月15日 Dolomite luster: Vitreous, pearly. Dolomite hardness: 3.5 to 4 (Harder than marble and limestone) Specific gravity: 2.84 2.86. Dolomite crystal: Trigonal system. The crystal is rhombohedral, the crystal plane is often curved into a saddle shape, and polycrystalline twins are common. Aggregates are usually granular.

process of dolomite using machine

2019-12-15T02:12:31+00:00 Process for Producing Dolomite Powder by feng li The main production equipment using dolomite mechanical grinding, crusher, sand making machine and milling machine The most used is dolomite mill, the

process of dolomite using machine Rechercher MC

Process Of Dolomite Using Machine Process of dolomite using machine Dolomite Its Processing and Application in Iron and Steel Industry . Jun 28, 2017 . The mai. process of dolomite using machine Rechercher 2019-11-10T05:11:01+00:00 Mobile Crushers.