Bed Material Vibrator Screen Limestone Processing Technology

Screening/Sizing McLanahan

Screening/Sizing. Sizing is the general separation of products according to their size. The simplest form of sizing is screening, the purpose of which is to separate minerals or other materials into specific particle sizes to

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日A-Z Guide to Screening Ore, RockAggregate. A simple definition of a “screen” is a machine with surface (s) used to classify

Vibrating Screen Working Principle Mineral Processing

IntroductionNamingMechanismApplicationsPurposeCauseUseSpecificationsSafetyOperationAssessmentCriticismsAnalysisExampleAdvantagesConstructionTypesDesign

The simplest Vibrating Screen Working Principle can be explained using the single deck screen and put it onto an inclined frame. The frame is mounted on springs. The vibration is generated from an unbalanced flywheel. A very erratic motion is developed when this wheel is rotated. You will find these simple screens in smaller operations and rock qua...

Efficient Circular Vibrating Screen Fote Machinery

1. Inclined vibrating screens/Circular motion vibrating screen. An inclined vibrating screen is one of the most popular screening machines. The inclination of this type of screen is at the range of 15 to 30 degrees.

Vibratory Screens General Kinematics

GK Home > Vibratory Screens A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of

Sand and Gravel 1150 Maxtrak Cone Crusher

Maxtrak 1150 Cone Crusher Processing Sand and Gravel. Background. At a sand and gravel deposit site in England, the 1150 Maxtrak cone crusher was working at a 20mm CSS. Crushed material (10-70mm) was then

Limestone Aggregates Processing SHANGHAI SANME MINING

The crushed material is larger than the size of the two-layer screen, and the stone is conveyed to the sand maker machine through the belt conveyor for fine crushing and

Products : Vibrating Screens : SINFONIA TECHNOLOGY

The Linear Drive Screen is a linear vibration heavy duty screen manufactured under our own outstanding vibration technologies and the screen technologies. Screening capacity is outstanding, and the

Y Vibrating Screen-mpl Industrial Technology Group

Product Features: Inheritance of classic design, simple and reliable vibrating screen Input Size: 0-400mm Capacity: 7.5-700TPH Material: Granite, marble, basalt, limestone, quartz, pebble, copper ore, iron ore,

Features : Vibrating Screens : SINFONIA TECHNOLOGY CO., LTD.

11 行RVS Type Rotary Vibrating Screen. Suitable for a wide variety of process in feed, , chemical, ceramic and other industries. Mainly middle sized materials up to

Sand and Gravel 1150 Maxtrak Cone Crusher

Crushed material (10-70mm) was then fed into a 3-deck vibrating screener. The customer was very pleased with the 1150 Maxtrak and later purchased one for his quarry. Setup 1150 Maxtrak Cone crusher Set at

Limestone Aggregates Processing SHANGHAI SANME MINING

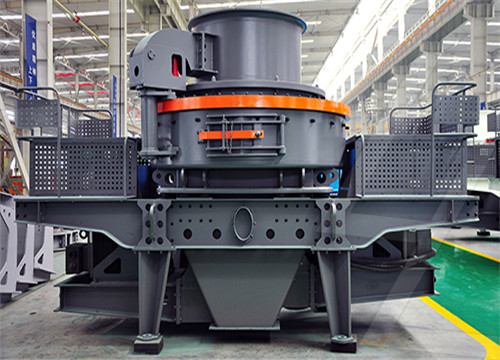

The Limestone sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and screening. The first stage: coarse crushing The pebbles blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. The second stage: medium broken

Industrial Vibrators Martin Engineering

One safe and efficient solution is the industrial vibrator, invented by Edwin F. Peterson in 1944, and the start of Martin Engineering. Martin Engineering manufactures vibrators to prevent bin and hopper flow problems as well as rotary electric vibratory drives for industrial processing equipment. The application of vibratory drives to

Limestone crushing plant, limestone grinding mill production line

Limestone processing flow. If the raw limestone is bigger than the input size of your grinding mill, it should be crushed firstly. The proposed limestone crusher is Impact Crusher, it can crush the material from 1m to –25 mm size. The crushed limestone will be sent by a belt conveyor to vibrating screen becoming final products or to grinding

Products : Vibrating Screens : SINFONIA TECHNOLOGY CO., LTD.

The Linear Drive Screen is a linear vibration heavy duty screen manufactured under our own outstanding vibration technologies and the screen technologies. Screening capacity is outstanding, and the effective processing of large quantities is possible, with a compact yet powerful exciter which generates alternating linear movement. The screen

Trommel Screens

Sand and Gravel Chieftain 2200 Inclined Screen; Sand and Gravel Warrior 1800 Screen; Sand and Gravel Premiertrak 400 and Maxtrak 1000; Basalt Premiertrak 600E and Warrior 2400; Grey Granite Premiertrak 600E Jaw Crusher ; River Bed Material Warrior 2400 Screen; Limestone and Shale 1150 Maxtrak Cone Crusher ; Mining. Overview:

Principles of Screening and Sizing MetallurgistMineral Processing

Principles of Screening and Sizing MetallurgistMineral Processing

Limestone Processing Plant in Lithuania Prominer (Shanghai)

Raw Material: Limestone Hardness: Moh’s 5.5 Site: Lithuania Processing Capacity:200tph. Feeding Size: 500mm. Discharge Size: 0-10-20-25mm. Main Equipment: Feeder+ jaw crusher+ impact crusher+vibrating screener. Application: Aggregate. icon Facebook; icon Twitter; icon Pinterest

Industrial Vibrators ElectricPneumatic Vibration for Material

We have the most complete line of industrial vibrators available with over 3000 models to suit your needs. Our industrial vibrators are available in pneumatic, electric and hydraulic power. We have experience in virtually all industries. Our industrial vibrators are explosion-proofenergy-efficient.

Attrition performance and morphology of limestone under

2021年10月1日Bed temperature was controlled at 850 °C to study the attrition characteristics of limestone. Quartz sand with size range (250-300 μm) was used as the bed material. The fluidizing gas velocity was 0.5 m/s which could maintain the bubbling state of quartz sand.

High-frequency vibrating screens Wikipedia

High-frequency vibrating screens usually operate at an inclined angle, traditionally varying between 0° and 25° and can go up to a maximum of 45°. They should operate with a low stroke and have a frequency ranging from 1500 to 9000 RPM. Frequency in High frequency screen can be fixed or variable.

S5X Vibrating Screen-mpl Industrial Technology Group

S5X Vibrating Screen. mpl's S5X Vibrating Screen is of high vibration intensity. Under the same specifications, it has larger processing capacity and higher screening efficiency compared to traditional screens. It is particularly applicable to heavy type, middle type and fine screening operations, and it is the ideal screening equipment for

Vibrating screener, Vibrating screening machine All industrial

Vibrating screeners companies products My filters vibrating Delete all Manufacturers A Abc Swisstech (1) AKW Apparate + Verfahren GmbH (1) ALLGAIER PROCESS TECHNOLOGY (3) AViTEQ Vibrationstechnik GmbH (2) AZO Group (5) B Binder+Co AG (2) BLIK (1) Group (1) C CAMEC srl (1) CONSTMACH Concrete Plants

Limestone Aggregates Processing SHANGHAI SANME MINING

The Limestone sand making process is divided into four stages: coarse crushing, medium fine crushing, sand making and screening. The first stage: coarse crushing The pebbles blasted from the mountain is fed uniformly by the vibrating feeder through the silo and transported to the jaw crusher for coarse crushing. The second stage: medium broken

Industrial Vibrators Martin Engineering

One safe and efficient solution is the industrial vibrator, invented by Edwin F. Peterson in 1944, and the start of Martin Engineering. Martin Engineering manufactures vibrators to prevent bin and hopper flow problems as well as rotary electric vibratory drives for industrial processing equipment. The application of vibratory drives to

Limestone crushing plant, limestone grinding mill production line

Vibrating Screen Limestone processing flow If the raw limestone is bigger than the input size of your grinding mill, it should be crushed firstly. The proposed limestone crusher is Impact Crusher, it can crush the material from 1m to –25 mm size.

Products : Vibrating Screens : SINFONIA TECHNOLOGY CO., LTD.

The Linear Drive Screen is a linear vibration heavy duty screen manufactured under our own outstanding vibration technologies and the screen technologies. Screening capacity is outstanding, and the effective processing of large quantities is possible, with a compact yet powerful exciter which generates alternating linear movement. The screen

S5X Vibrating Screen-mpl Industrial Technology Group

S5X Vibrating Screen. mpl's S5X Vibrating Screen is of high vibration intensity. Under the same specifications, it has larger processing capacity and higher screening efficiency compared to traditional screens. It is particularly applicable to heavy type, middle type and fine screening operations, and it is the ideal screening equipment for

Trommel Screens

Sand and Gravel Chieftain 2200 Inclined Screen; Sand and Gravel Warrior 1800 Screen; Sand and Gravel Premiertrak 400 and Maxtrak 1000; Basalt Premiertrak 600E and Warrior 2400; Grey Granite Premiertrak 600E Jaw Crusher ; River Bed Material Warrior 2400 Screen; Limestone and Shale 1150 Maxtrak Cone Crusher ; Mining. Overview:

Principles of Screening and Sizing MetallurgistMineral Processing

Principles of Screening and Sizing MetallurgistMineral Processing

Limestone Processing Plant in Lithuania Prominer (Shanghai)

Raw Material: Limestone Hardness: Moh’s 5.5 Site: Lithuania Processing Capacity:200tph. Feeding Size: 500mm. Discharge Size: 0-10-20-25mm. Main Equipment: Feeder+ jaw crusher+ impact crusher+vibrating screener. Application: Aggregate. icon Facebook; icon Twitter; icon Pinterest

Industrial Vibrators ElectricPneumatic Vibration for Material

We have the most complete line of industrial vibrators available with over 3000 models to suit your needs. Our industrial vibrators are available in pneumatic, electric and hydraulic power. We have experience in virtually all industries. Our industrial vibrators are explosion-proofenergy-efficient.

AViTEQ: Linear vibrating screen

AViTEQ-Vibrating screen are robust, durable, bulk material adapted heavy workers, which are used as discharge units with integrated screening function below a silo, hopper or bunker or to provide a feed to a belt conveyor or crusher.Depending on the task, the devices are designed with a robust inlet area with liners (wearing plates) followed by two or three

Hard Limestone Maxtrak and Chieftain

Maxtrak and Chieftain Processing Hard Limestone. At this site in Duleek, a 1150 Maxtrak Pre-Screen crushed blasted hard Limestone (Abrasive) and a Chieftain 2100X screened the product. The engineer on site was full of praise for the 1150 Maxtrak Pre-Screen, stating that it was a perfect machine for them in

Sifting Process Technology Contact us Dinnissen BV

Vibrating the vibrating deck causes the material to move. The material that is fine enough falls through the perforations of the sifting deck. The mixtures to be sifted are often fed in by dosed dumping. The Vibrating Sifter should be mounted on a solid surface to prevent secondary vibrations from occurring at all.

Mining Vibrating Screen GN Separation Equipment Manufacturer

Flip-Flow Vibrating Screen Polyurethane Screen Panel-Coarse Screening Polyurethane Screen Mesh- Fine Screening GN Mining Vibrating Screen main application materials: Metal Minerals: iron ore, copper ore, aluminum ore, gold ore, lead ore, zinc ore, platinum ore, chromium ore, manganese ore, etc.

- Flow Diagram Of Copper Ore Mining To Refining Process

- Technical Support Ball Mill Ball Mill With Perfect Services

- 叶腊石生产设备一览表

- 碎花岗岩的比重

- 粗碎直线振动筛

- 蹇犲瓭浠佺埍淇′箟鍜屽钩

- 破碎、磨粉、制沙

- 一整套550TPH磨粉生产线价格

- With Producing Jaw Crusher

- Planetary Ball Mill With Ce Approved 2l Mining Ball Grinding Mill For Sale

- 铝矾土炼铝工艺

- 选软铁矿设备

- 螺栓的紧固方法

- 大型锚杆钻机

- Wet Ball Mill Ball Mill Manufacturers In Uk