Silicon Ore Beneficiation Equipment

Quartz Ore Beneficiation by Reverse Flotation for Silicon

Silicon Production Sidali Medjahed, Abdelkrim Kheloufi, Ema Bobocioiu, Aissa Kefaifi, Fouad Kerkar, Kheirreddine Lebbou To cite this version: Sidali Medjahed, Abdelkrim Kheloufi, Ema Bobocioiu, Aissa Kefaifi, Fouad Kerkar, et al.. Quartz Ore Beneficiation

Quartz Ore Beneficiation by Reverse Flotation for

on silicon solar cells and reducing the cost of silicon wafers [1]. Due to the advantages of low production cost and rela-tively high conversion efficiency, multicrystalline silicon has

An Efficient and Sustainable Approach for Preparing

2019年7月12日Silicon fertilizer was prepared by converting crystalline silicon dioxide, which is widely distributed in gangue minerals after ore beneficiation, into plant

Silica Mining Processing Equipment Flow Chart Cases

Silicon is used in the aluminum industry to improve castability and weldability. Silicon-aluminum alloys tend to have relatively low strength and ductility, so other metals, especially magnesium and copper, are often

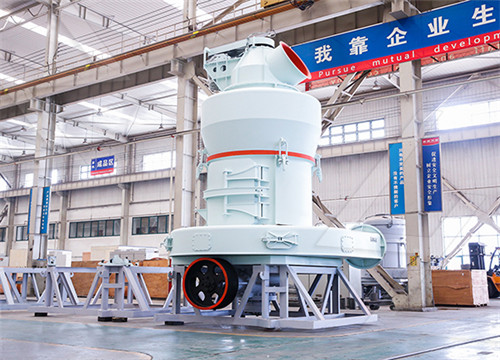

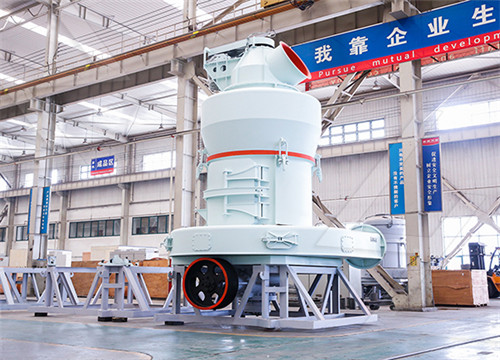

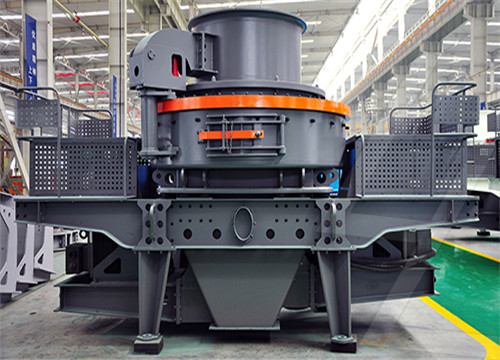

Mining and Mineral Processing Equipment Supplier ZJH

2019年2月17日Founded in 1987, ZJH is mainly focus on producing and supply crushers,ore grinding equipment, mineral beneficiation equipment (mainly froth

Quartz Ore Mining SolutionEquipment Mineral

Quartz, also known as silica, is a common non-metallic mineral raw material with a wide range of applications. The high-purity and ultra-high-purity quartz made by beneficiation and purification has been widely used in high

Separation and purification of high-purity quartz from high-silicon

2023年1月1日The iron ore tailing sample was a granular high-silicon solid waste obtained after the beneficiation process of iron ore following the steps of stage grinding–gravity

Beneficiation Equipment PlantMachinery Medical

Iron Ore (Hematite)43% to 62%+, 19.5% to 63.2%; Manganese ore 18% to 38%; KINC’s IOBP plant for iron ore beneficiation is milestone in a journey of excellence. Capable to execute beneficiation plant on EPC, concept

A Complete Solution for Nickel Ore Processing Fote Machinery

2023年2月15日Jaw crusher: Crush silicon-magnesium-nickel ore. Screening equipment needs to be installed before or after the crusher to throw away the waste rock in time.

Iron Ore Mining Equipment Iron Ore Beneficiation CDE CDE

Our iron ore beneficiation washing solutions are helping mine operators to convert millions of tons of low grade iron ore into high-value saleable products. Iron Ore Mining

Quartz Ore Beneficiation by Reverse Flotation for Silicon

2020年10月31日A preliminary enrichment using reverse flotation process improves the silica purity up to 99.6% and removes the major impurities, which is suitable intermediate technological product able for silicon production and optical application. Download to read the full article text

An Efficient and Sustainable Approach for Preparing Silicon Fertilizer

2019年7月12日The equipment required for traditional silicon fertilizer production plants mainly includes a hoister, dryer, screw conveyor, ball mill, mixer, handheld sack closer, and other auxiliary equipment. Compared with traditional silicon fertilizer production, this approach requires extra roasting equipment.

Quartz Ore Mining SolutionEquipment Mineral

Quartz, also known as silica, is a common non-metallic mineral raw material with a wide range of applications. The high-purity and ultra-high-purity quartz made by beneficiation and purification has been widely used in high

Quartz Ore Beneficiation by Reverse Flotation for Silicon

Quartz Ore Beneficiation By Reverse Flotation For Silicon Production Sidali MEDJAHED1, Abdelkrim KHELOUFI 1*, Ema BOBOCIOIU 2, Aissa KEFAIFI 1, Fouad Kerkar 1, Kheirreddine LEBBOU 3 *Corresponding author: Abdelkrim Kheloufi [email protected] 1Centre de Recherche en Technologie des semi-conducteurs pour l’Energétique, Bd

Quartz Ore Beneficiation by Reverse Flotation for

2022年1月1日In this work the reverse flotation as beneficiation process for high-purity silica valorization from Draissa quartz deposits (Algeria) is studied as a potential raw material for photovoltaic

Separation and purification of high-purity quartz from high-silicon

2023年1月1日The iron ore tailing sample was a granular high-silicon solid waste obtained after the beneficiation process of iron ore following the steps of stage grinding–gravity separation–magnetic separation–anion reverse flotation. The sample had a size distribution ranging from 0.42 to 831.76 µm.

Beneficiation Equipment PlantMachinery

Iron Ore (Hematite)43% to 62%+, 19.5% to 63.2%; Manganese ore 18% to 38%; KINC’s IOBP plant for iron ore beneficiation is milestone in a journey of excellence. Capable to execute beneficiation plant on EPC, concept

Forui Mining Machinery Co.,Ltd Home Facebook

+86 180 2697 8087 asa.guo@foruimining Mining Company CommercialIndustrial Equipment Supplier Industrial Company Gongyi Forui Machinery Factory is founded in 1986. We are one of the leading

Iron Ore Mining Equipment Iron Ore Beneficiation CDE CDE

Iron Ore Mining Equipment Achieve a Higher Fe Content. Efficiently remove silica, alumina, clay, and other contaminants from your feed material to increase the Fe value in the final ore. Our iron ore beneficiation projects have increased the Fe content from 43% in the feed to above 60% in the final iron ore product, ensuring increased

Minerals Free Full-Text Process Mineralogy Characteristics and

2021年11月10日A refractory phosphate ore obtained from Guizhou, China, contains high amounts of detrimental metal impurities (e.g., Fe, Al, and Mg) which affect the deep wet processing of phosphorus products before use. In this study, mineralogy parameters of the ore such as mineral composition, disseminated particle size, mineral liberation degree,

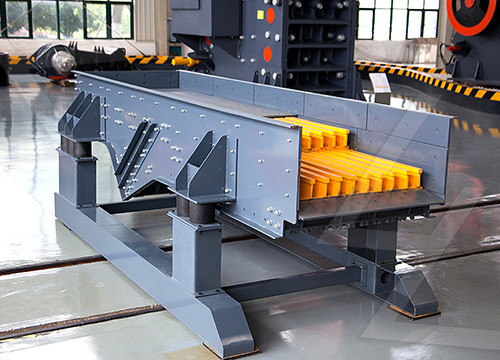

What Are Manganese Ore Beneficiation Equipment? Xinhai

2022年6月24日The main application of gravity separation equipment are: jig, shaking table, cyclone and so on. Jig machine: The jig machine is suitable for processing coarse-grained manganese minerals and has a better effect on desilication. At the same time can also remove part of the iron.

Beneficiation an overview ScienceDirect Topics

Copper Production. W.G. Davenport, in Encyclopedia of Materials: Science and Technology, 2001 1.1 Physical Beneficiation. Beneficiation of copper ores is done almost exclusively by selective froth flotation. Flotation entails first attaching fine copper mineral particles to bubbles rising through an ore–water pulp and, second, collecting the copper minerals at

Manganese ore beneficiation methods and equipment summary!

2022年1月19日At present, the commonly used manganese ore beneficiation methods mainly include mechanical beneficiation (ore washing, screening, gravity separation, strong magnetic separation and flotation) and

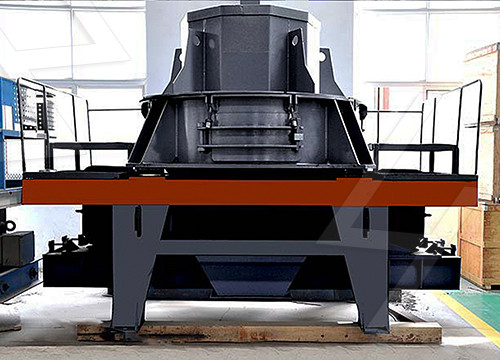

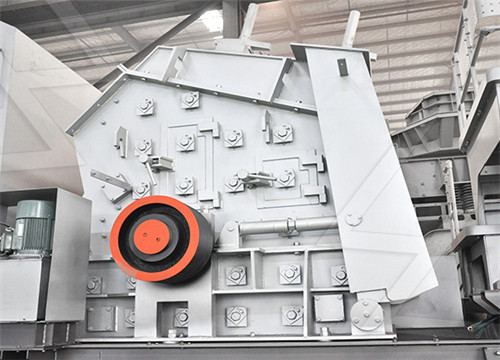

Nickel Ore Beneficiation Plant Mineral Processing

Nickel ore processing usually needs to go through three processes: crushing screening- grinding- flotation separation- drying, and magnetic separation and gravity separation are usually auxiliary beneficiation methods. 1. Crushing and screening: The feeder sends the mined raw ore to the jaw crusher for coarse crushing.

Quartz Ore Beneficiation by Reverse Flotation for Silicon

2020年10月31日A preliminary enrichment using reverse flotation process improves the silica purity up to 99.6% and removes the major impurities, which is suitable intermediate technological product able for silicon production and optical application. Download to read the full article text

A review of intelligent ore sorting technology and equipment

2022年7月25日Under the background of increasingly scarce ore worldwide and increasingly fierce market competition, developing the mining industry could be strongly restricted. Intelligent ore sorting equipment not only improves ore use and enhances the economic benefits of enterprises but also increases the ore grade and lessens the

Quartz Ore Beneficiation by Reverse Flotation for Silicon

Quartz Ore Beneficiation By Reverse Flotation For Silicon Production Sidali MEDJAHED1, Abdelkrim KHELOUFI 1*, Ema BOBOCIOIU 2, Aissa KEFAIFI 1, Fouad Kerkar 1, Kheirreddine LEBBOU 3 *Corresponding author: Abdelkrim Kheloufi [email protected] 1Centre de Recherche en Technologie des semi-conducteurs pour l’Energétique, Bd

Quartz Ore Mining SolutionEquipment Mineral

Quartz, also known as silica, is a common non-metallic mineral raw material with a wide range of applications. The high-purity and ultra-high-purity quartz made by beneficiation and purification has been widely used in high

Quartz Ore Beneficiation by Reverse Flotation for

2022年1月1日In this work the reverse flotation as beneficiation process for high-purity silica valorization from Draissa quartz deposits (Algeria) is studied as a potential raw material for photovoltaic...

Beneficiation Equipment PlantMachinery

Iron Ore (Hematite)43% to 62%+, 19.5% to 63.2%; Manganese ore 18% to 38%; KINC’s IOBP plant for iron ore beneficiation is milestone in a journey of excellence. Capable to execute beneficiation plant on EPC, concept

Forui Mining Machinery Co.,Ltd Home Facebook

+86 180 2697 8087 asa.guo@foruimining Mining Company CommercialIndustrial Equipment Supplier Industrial Company Gongyi Forui Machinery Factory is founded in 1986. We are one of the leading

Minerals Free Full-Text Process Mineralogy Characteristics and

2021年11月10日A refractory phosphate ore obtained from Guizhou, China, contains high amounts of detrimental metal impurities (e.g., Fe, Al, and Mg) which affect the deep wet processing of phosphorus products before use. In this study, mineralogy parameters of the ore such as mineral composition, disseminated particle size, mineral liberation degree,

[PDF] Quartz Ore Beneficiation by Reverse Flotation for Silicon

In this work the reverse flotation as beneficiation process for high-purity silica valorization from Draissa quartz deposits (Algeria) is studied as a potential raw material for photovoltaic silicon production and starting charge for crystal growth material for a large wide of applications such laser and scintillation. The samples are investigated by optical

Iron Ore Mining Equipment Iron Ore Beneficiation CDE CDE

Our iron ore beneficiation washing solutions are helping mine operators to convert millions of tons of low grade iron ore into high-value saleable products. Iron Ore Mining Equipment Achieve a Higher Fe Content Efficiently remove silica, alumina, clay, and other contaminants from your feed material to increase the Fe value in the final ore.

Beneficiation an overview ScienceDirect Topics

Ore beneficiation refers to the selection and collection of higher-grade ore fragments or rejection of lower-grade fragments from ROM ore. The upgraded ore will have a higher grade, and therefore require a smaller-scale processing plant, perhaps with different technology, compared to ROM ore.

Nickel Ore Beneficiation Plant Mineral Processing

Nickel ore processing usually needs to go through three processes: crushing screening- grinding- flotation separation- drying, and magnetic separation and gravity separation are usually auxiliary beneficiation methods. 1. Crushing and screening: The feeder sends the mined raw ore to the jaw crusher for coarse crushing.

Manganese ore beneficiation methods and equipment summary!

2022年1月19日At present, the commonly used manganese ore beneficiation methods mainly include mechanical beneficiation (ore washing, screening, gravity separation, strong magnetic separation and...

Ore Beneficiation an overview ScienceDirect Topics

Iron ore beneficiation can be brought about through three approaches, namely, selective dissolution, microbially induced flotation, and selective flocculation–dispersion. The bioprocesses are specially suited to treat fines, slimes, and waste tailings. 4. Potential applications include.