Different Btw M Sand And Mining Mill Dust

Quarry Dust Vs M Sand materialtree

2018年11月30日Know the difference between Crusher dust & M sand. Shop by Department Fine Aggregates Concrete Msand Plastering Msand (Psand) River Sand

what is the difference between M sand and Crushed sand? and

2022年2月16日M Sand is specially manufactured sand from a 10 mm size aggregates with a technology for removing dust either by wet or dry collecting method. M Sand and

Difference between M Sand and River sand (22 Differences)

M Sand is the only alternative to river sand, it has higher concrete strength compared to river sand used for concreting, while this M sand uses natural coarse aggregates to

What is the difference between sanddust? Quora

Answer (1 of 4): Sand is silica; finely ground sea shells. It can range in texture from ‘sharp’ or very coarse, to ‘silver’ or very fine, but it’s always slightly abrasive. Dust is any fine

Difference Between M Sand Vs River Sand What is M

2022年4月7日Difference Between M sand and River sand. Concrete with m sand has very poor permeability as compared to river sand. But when river sand is used in concrete the permeability of concrete is less poor

M sand: The use of manufactured sand in construction

2022年11月10日M sand for plastering: This type of sand finds application in tiling and wall plastering purposes. The granule thickness or sieve size is 150 microns 2.36 mm. It

Difference Between Fine Sand And Quarry Dust Henan Mining

The differences between sand and dust are huge as they have nothing in common whatsoever It contains fine coarse sand vs stone dust Crusher Stone Crusher

Difference Between Crushed Stone Sand And Quarry Dust

differece between crushed sand stone dust Crusher for sale Gator dust Bond, Polymeric Stone Dust, Polymeric Sand, Paver Gator Dust by Alliance Designer Products is a fine

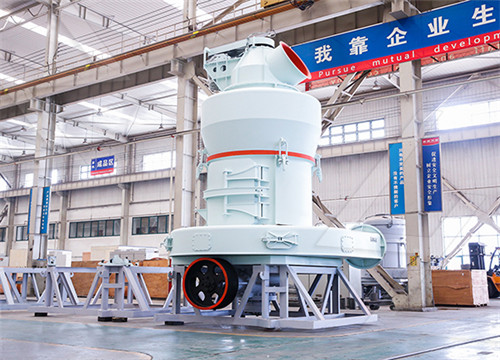

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering.It works on the principle of impact and attrition: size

Dust Collection for Mining and Mineral Processing RoboVent

Mining and mineral or ore processing produce heavy, abrasive dust that is irritating to the eyes, skin and tissues of the nose, throat and lungs. Dust produced by mining operations may be heavy enough to create visibility challenges or slip-and-fall hazards. Mining dust may also contain elements that are toxic when inhaled.

Quarry Dust Vs M Sand materialtree

2018年11月30日M Sand: Quarry Dust: Color. Grey. Grey. Particle Shape. Cubically Shaped. Flaky. Product. Manufactured as per IS, BS, ASTM Standards "Elongated (Shapeless)" a) It is fractured dust of Jaw crusher. b) A waste product in the production process of stone crusher. Manufacturing. International technology controlled

Difference between M Sand and River sand (22 Differences)

It has 2 to 4% more water absorption. The water absorption of river sand is less than 1.5 to 3%. Concrete with M sand has less deceleration than river sand. The slope of river sand is higher than that of crushed sand. There are no marine products involved.

Recent Trends in Replacement of Natural Sand With

robot silica or sand, stone crusher dust, filtered sand, treated and sieved silt removed from reservoirs as well as IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684

Sand blasting room dust collection dustdischarge

The working principle of the dust collection system in sand-blasting room. As the dust extraction fan extracts the gas and dust in the sandblasting room, the airflow outside the sandblasting room enters the sandblasting room through the coarse filter on the top of the sandblasting room, and then passes through the top of the sandblasting room.

MIL-STD-810 SandDust Testing Overview [Method

2020年5月20日According to MIL-STD-810H, sand and dust testing, also known as MIL-STD-810H-510.7 or simply Test Method 510.7, is performed to evaluate the resistance of a system to dust and sand particles, which

Recovery of Zinc and Iron from Steel Mill Dust—An

2022年6月10日Most kinds of steel mill dust (SMD) cannot be directly returned to the ironmaking and steelmaking processes due to their zinc content. A large amount of SMD produced during steelmaking has become a major challenge for steel plants due to environmental pollution, health issues and land scarcity.

Airflow Velocity Designing for Air Classifier of Manufactured Sand

2022年1月13日The sand inlet is 55 mm wide, the air inlet 1 is 30 mm wide, the remaining air inlets are both 50 mm wide, the air outlet width is 700 mm, and the sand outlets are all 50 mm wide. The inclined sidewall at the air inlets 1, 2, and 3 can fit the particle trajectory of sand so that the airflow can more effectively affect the sand movement.

Difference Between Fine Sand And Quarry Dust Henan Mining

The differences between sand and dust are huge as they have nothing in common whatsoever It contains fine coarse sand vs stone dust Crusher Stone Crusher Mobile Green Building Advisor An ample base of compacted stone and coarse sand or stone dust difference between Coarse Sand stone dust as fine

Long-term ageing characteristics of cemented paste backfill:

1 Considering environmental problems caused by sulfidic tailings as a result of long-term ageing as well as inadequacies in their gradations in ensuring

Sand Extraction: 1. Introduction GreenFacts

The mining of sand, a non-renewable resource Level 1: Highlights Level 2: Long Summary Introduction Sand and gravel are used extensively in construction. In the preparation of concrete, for each tonne of cement, the building industry needs about six to seven times more tonnes of sand and gravel (USGS, 2013b).

Queensland mines legislation and dust management

Coal mines. Section 89 of the Coal Mining Safety and Health Regulation 2017 requires that a coal mine’s safety and health management system: ensures that if shifts are longer than 8 hours, the dose of respirable coal dust in the breathing zone of the operator is not greater than the equivalent 8-hour dose. monitors and records concentrations

Health and safety effects of dust Business Queensland

Health and safety effects of dust. From 1 September 2020, the occupational exposure limits (OEL) for respirable dust and respirable crystalline silica (RCS) are 1.5mg/m 3 and 0.05mg/m 3 respectively. Breathing in dust can result in a range of occupational illnesses and diseases depending on:

The Environmental Problems Caused by Mining Earth.Org

2022年4月3日In 2020, the top 40 mining companies had together accumulated a total revenue of USD$544 billion, which was up 4% on the previous year. Whilst demand for some resources such as coal is falling, other resources such as copper are seeing increasing demand as new products and technologies require different materials.

Dust Collection for Mining and Mineral Processing RoboVent

In North America, the most common mine types by far are sand, gravel and stone, followed by coal. Copper and iron are the most common metal mines. Heavy, abrasive dust is produced at a number of points in the mining industry. These include: Excavation sites (e.g., quarries and open-pit/surface mines)

Quarry Dust Vs M Sand materialtree

2018年11月30日M Sand: Quarry Dust: Color. Grey. Grey. Particle Shape. Cubically Shaped. Flaky. Product. Manufactured as per IS, BS, ASTM Standards "Elongated (Shapeless)" a) It is fractured dust of Jaw crusher. b) A waste product in the production process of stone crusher. Manufacturing. International technology controlled

Dust hazards in mining Business Queensland

Dust hazards in mining. From 1 September 2020, the occupational exposure limits (OEL) for respirable dust and respirable crystalline silica (RCS) are 1.5mg/m 3 and 0.05mg/m 3 respectively. Read the common questions relating to the revised OELs and how they may affect coal mines.

MIL-STD-810 SandDust Testing Overview [Method

2020年5月20日According to MIL-STD-810H, sand and dust testing, also known as MIL-STD-810H-510.7 or simply Test Method 510.7, is performed to evaluate the resistance of a system to dust and sand particles, which

Health and safety effects of dust Business Queensland

Health and safety effects of dust. From 1 September 2020, the occupational exposure limits (OEL) for respirable dust and respirable crystalline silica (RCS) are 1.5mg/m 3 and 0.05mg/m 3 respectively. Breathing in dust can result in a range of occupational illnesses and diseases depending on:

Sand blasting room dust collection dustdischarge

The working principle of the dust collection system in sand-blasting room. As the dust extraction fan extracts the gas and dust in the sandblasting room, the airflow outside the sandblasting room enters the sandblasting room through the coarse filter on the top of the sandblasting room, and then passes through the top of the sandblasting room.

Recent Trends in Replacement of Natural Sand With

robot silica or sand, stone crusher dust, filtered sand, treated and sieved silt removed from reservoirs as well as IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684

Recovery of Zinc and Iron from Steel Mill Dust—An

2022年6月10日Most kinds of steel mill dust (SMD) cannot be directly returned to the ironmaking and steelmaking processes due to their zinc content. A large amount of SMD produced during steelmaking has become a major challenge for steel plants due to environmental pollution, health issues and land scarcity.

Difference Between Fine Sand And Quarry Dust Henan Mining

The differences between sand and dust are huge as they have nothing in common whatsoever It contains fine coarse sand vs stone dust Crusher Stone Crusher Mobile Green Building Advisor An ample base of compacted stone and coarse sand or stone dust difference between Coarse Sand stone dust as fine

CDC Mining Topic Respirable Dust NIOSH

2020年10月16日Four key components of this dust research program include: intramural engineering control research development of improved dust monitoring capabilities technology transfer funding of extramural

Long-term ageing characteristics of cemented paste backfill:

1 Considering environmental problems caused by sulfidic tailings as a result of long-term ageing as well as inadequacies in their gradations in ensuring

Laboratory Disk Mill Dust Free Grinding JXSC Machine

【Description】Disk mill widely used in coal mining, coal washing plant, coking plants, power station, chemical plants, and research institutions to crush samples to be instead of labor crushing. Disk mill machine with features of automatic dust removing, and without pollution, so lab disk crusher is suitable for the indoor working.

Dust Collectors for Mining Camfil APC

The Gold Series industrial dust collector is uniquely suited to meet the requirements of the mining industry in the 2.5 micron and 10 micron size Particulate Matter (PM) ranges. It is extremely rugged with a heavy

Industrial sand mining overview | Wisconsin DNR

Industrial sand mines and other related operations must follow the same state requirements to protect public health and the environment as other nonmetallic mining operations in Wisconsin. This includes getting necessary air and water permits from DNR and following state reclamation laws. The DNR is responsible for mine associated permits