Defect On Rolls Inrolling Mills

1. Hot rolling and rolling defects: 1.1 Front and back

Reducing the roll gap increases the roll pressure to p3. Gage control in multiple rolling mills is achieved through measurement of strip thickness using x-ray gage and adjusting the strip tension using feedback control system. 1.8 Rolling defects: Mill spring is a defect in

Abnormalities and Failures of Rolling Mill Rolls IspatGuru

根据热度为您推荐•反馈

Rolling Process: Working, Application, Defects, Type of

2023年3月3日Following are the types of defects in rolling: Surface rolling defects Internal structural rolling defects Surface Defects: Surface

What are the possible Rolling Defects? ExtruDesign

2022年4月20日These defects include the following: (i) Wavy edges (ii) Zipper cracks (iii) Edge cracks (iv) Centre split (v) Alligatoring (vi) Folds (vii) Laminations Wavy edges and

Common Rolling Defects and How to Combat Them

One of the most common rolling defects is the occurrence of fibers at the edge, which are longer than those at the center. This occurs when concave rolls bend leading to elastic deformations. Thickness at the center

6 Sheet Metal Rolling Defects and How to Avoid Them

Another common sheet rolling defect is wavy edges. Your workpiece can become thinner on the edges and thicker in the middle, creating wavy, uneven edges. This may happen

Different types of rolling mills and defects in rolled metal

2020年6月5日The following stated below represent the common types of defects of rolling: Wavy edges crack: These types of rolling defects can occur in different cases, which may be caused by the deflection of the

What is Rolling Process: Definition, Working, Types,

Rolling Process is a deformation process in which Metal (s) in its semi-finished or finished form is passed between the two opposing rollers, which reduces the metal’s thickness

Chatter problems on a cold rolling mill Innoval Technology

2016年7月14日The defect appeared as alternative light and dark transversal stripes on both surfaces of the strip. Also, the stripes were exactly perpendicular to the rolling direction. Furthermore, the spacing of

Rolling Mills: 6 Different Types of Rolling Mills [Images

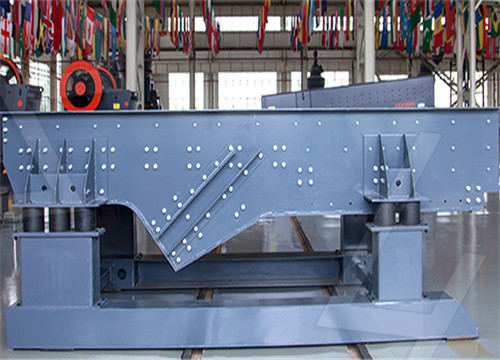

2022年5月24日The rolls are supported in bearing housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor. The vertical gap between the roll is adjustable. The rolls rotate in opposite

Research on the Cause and Control Method of Edge Warping Defect

Different from the cross-section profile defects caused by uneven roll wear or external forces during hot finishing rolling, the edge warping defect often occurs and has special local characteristics. However, the cause and control method of edge warping are still unclear. By superposition calculating the roll shape, it is found that the high-order

1. Hot rolling and rolling defects: 1.1 Front and back tensions

Reducing the roll gap increases the roll pressure to p3. Gage control in multiple rolling mills is achieved through measurement of strip thickness using x-ray gage and adjusting the strip tension using feedback control system. 1.8 Rolling defects: Mill spring is a defect in which the rolled sheet is thicker than the required thickness because,

Common Rolling Defects and How to Combat Them

One of the most common rolling defects is the occurrence of fibers at the edge, which are longer than those at the center. This occurs when concave rolls bend leading to elastic deformations. Thickness at the center

v116n10a3 Investigation of the ‘tiger skin’ defect on

6785/-27:56 Hot strip mills (HSMs) are used to roll cast steel slabs from their initial size to plate or sheet, which is then used to manufacture a

sbm/sbm on defect on rolls inrolling mills customer case.md at

Contribute to changjiangsx/sbm development by creating an account on GitHub.

6 Sheet Metal Rolling Defects and How to Avoid Them Regan

Another common sheet rolling defect is wavy edges. Your workpiece can become thinner on the edges and thicker in the middle, creating wavy, uneven edges. This may happen when there is a deflection involved under the load in a rolling machine. You could use hydraulic jacks to prevent wavy edges.

Forging Defects On Rolling Mill Rolls

April 23rd, 2018 Drawing Defects Forging Defects Rolling Defects Alligatoring 9Cr 1Mo steel Rolling defects The AR plates were rolled in a two high mill roll diameter 190 mechanical engineering Types of rolling mills

Forging Defects On Rolling Mill Rolls gitlab.dstv

Forging Defects On Rolling Mill Rolls pdfsdocuments2 com. Seamless Rolled Ring Forgings Philadelphia Forgings. MECHANIK NR 11 2017 Design and technological capabilities. New type of groove used to improve friction in roll forging. China Rolling Mill Rolls Supplier Manufacturer Factory. MANUFACTURING TECHNOLOGY WordPress com

Forging Defects On Rolling Mill Rolls Pdf [PDF]

Forging Defects On Rolling Mill Rolls Pdf Eventually, you will enormously discover a other experience and realization by spending more cash. still when? do you agree to that you require to get those all needs bearing in mind having significantly cash? Why dont you

Forging Defects On Rolling Mill Rolls .pdf

2 Forging Defects On Rolling Mill Rolls 2021-09-06 Mechanical Engineering of APJ Abdul Kalam Technological University, Kerala. The Results of Ultrasonic Testing in the Practice of Machine and Boiler Construction Concerning the Material and Strength Properties of Components Firewall Media

sbm defect on rolls inrolling mills customer case.md main

M mill Project information Project information Activity Labels Members Repository Repository Files Commits Branches Tags Contributors Graph Compare Issues 0 Issues 0 List Boards Service Desk Milestones Merge requests 0 Merge requests 0 CI/CD CI/CD Pipelines Jobs Schedules Deployments Deployments Environments Releases Packages

Interface phenomena and bonding mechanism in the new method

1 In this work, we conducted experiments to investigate the interface quality and bonding mechanism of the proposed process. As Fig. 1 shows, rolling experiments were carried out to produce the 42CrMo/Q235 bimetallic shafts under different process parameters, and then the forming defects were analyzed. The interface quality of roll

Development of high-speed tool steel rolls and their application

Steel rolling technology has progressed in recent years, improving prod- ust quality, enhancing productivity, and reducing production costs. This trend has increased the demand for rolling mill rolls

Metal Rolling Manufacturing Process

Defects In Metal Rolling A wide variety of defects are possible in metal rolling manufacture. Surface defects commonly occur due to impurities in the material, scale, rust, or dirt. Adequate surface preparation prior to the

Research on the Cause and Control Method of Edge Warping Defect

Different from the cross-section profile defects caused by uneven roll wear or external forces during hot finishing rolling, the edge warping defect often occurs and has special local characteristics. However, the cause and control method of edge warping are still unclear. By superposition calculating the roll shape, it is found that the high-order

Rolling Mill: Common Rolling Defects And Solutions

2021年9月23日Rolling Mill: Common Rolling Defects And Solutions. Sep. 23, 2021. Share: Rolling is the procedure in which a steel supply goes through rollers to lower as well as combine thickness. Metal rolling has actually come a long way, from the conventional hand procedures to the state-of-the-art commercial approaches.

v116n10a3 Investigation of the ‘tiger skin’ defect on

6785/-27:56 Hot strip mills (HSMs) are used to roll cast steel slabs from their initial size to plate or sheet, which is then used to manufacture a

Metal Rolling Manufacturing Process

Defects In Metal Rolling A wide variety of defects are possible in metal rolling manufacture. Surface defects commonly occur due to impurities in the material, scale, rust, or dirt. Adequate surface preparation prior to the

Sheet Camber and Cambering of Rolls Metallurgy

If the deflection of roll during rolling is equal to the camber ground on the roll the sheet rolled would be flat. Since sheets of various widths may be rolled on the same pair of rolls and with different reductions, no one camber may suit all conditions of rolling.

Interface phenomena and bonding mechanism in the new method

1 In this work, we conducted experiments to investigate the interface quality and bonding mechanism of the proposed process. As Fig. 1 shows, rolling experiments were carried out to produce the 42CrMo/Q235 bimetallic shafts under different process parameters, and then the forming defects were analyzed. The interface quality of roll

Forging Defects On Rolling Mill Rolls

April 23rd, 2018 Drawing Defects Forging Defects Rolling Defects Alligatoring 9Cr 1Mo steel Rolling defects The AR plates were rolled in a two high mill roll diameter 190 mechanical engineering Types of rolling mills

Forging Defects On Rolling Mill Rolls gitlab.dstv

Forging Defects On Rolling Mill Rolls pdfsdocuments2 com. Seamless Rolled Ring Forgings Philadelphia Forgings. MECHANIK NR 11 2017 Design and technological capabilities. New type of groove used to improve friction in roll forging. China Rolling Mill Rolls Supplier Manufacturer Factory. MANUFACTURING TECHNOLOGY WordPress com

Forging Defects On Rolling Mill Rolls Pdf [PDF]

Forging Defects On Rolling Mill Rolls Pdf Eventually, you will enormously discover a other experience and realization by spending more cash. still when? do you agree to that you require to get those all needs bearing in mind having significantly cash? Why dont you

Forging Defects On Rolling Mill Rolls .pdf

2 Forging Defects On Rolling Mill Rolls 2021-09-06 Mechanical Engineering of APJ Abdul Kalam Technological University, Kerala. The Results of Ultrasonic Testing in the Practice of Machine and Boiler Construction Concerning the Material and Strength Properties of Components Firewall Media

Development of high-speed tool steel rolls and their application

Steel rolling technology has progressed in recent years, improving prod- ust quality, enhancing productivity, and reducing production costs. This trend has increased the demand for rolling mill rolls

Roll Inspection ControlMeasuring Technology

In order to minimize downtime in hot rolling mills, it is important to identify defect rolls early. This is why HCC/KPM has developed surface inspection technologies that reliably locate cracks and other defects near the

(PDF) Review on Cold Rolling Mill Roll Deformation

2017年5月25日The main objective is to highlight those reasons which are responsible for the breakage. The parameters considered during the manufacturing and during the regular use of rolls in cold rolling in...