Vibrating Screen For Plaster Bengkulu?

VIBFEM M Sand High Frequency Screen, Vibrating Screen

We offer M sand High Frequency Screen (VIBFEM HFF Screen) for manufacturing construction sand as per IS 383 Zone II and plaster sand

Vibrating Screens Vibramech

Vibramech screens are equipped with vibrator motor, geared exciter or oscillator drives, and are available in single-, double- or triple-deck configuration. The range of screening media includes polyurethane

Vibratory Screens General Kinematics

Vibratory Screens. A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries. From

Vibrating Screens Kinergy

Kinergy Vibrating Screens are the most Energy Efficient, require minimal maintenance, operate quietly and have an electrically adjustable stroke and operating frequency. All of these features combine to ensure the best

Industrial Vibrating Screens AdvantagesIts Uses

Lower Operational CostsLess MaintenanceImproved Material ProcessingHigher Screening EfficiencyConclusion

Among a plethora of screening equipment available in the machinery market, the vibrating screens proffer the most durable solution to control the flow of higher feed. With this being said, vibrating screens functions at its peak on a consistent flow rate. The same screener can also uphold the backflow of materials which requires a slower feed.

Large Vibrating Screen DesignMaintenance

2018年10月16日Large vibrating screens represent a unique challenge for Manufacturers, Plant Designers, and Plant Operators. The inherent mode of operation for vibrating screens is self-destructive. More often than

Homemade Soil Screener/sifter : 11 Steps (with Pictures)

This soil screener features springs and hinges made from old car tires so there is no need for regular steel springs and metal hinges (and the major hassle mounting them).The

Vibrating screen SKF

Vibrating screen. This example shows the bearing selection process applied to an application case in which a vibrating screen manufacturer is selecting the bearings for a

best Beneficiation equipment for Plaster Bengkulu

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

vibrating-screens: plaster based powder filler greek Indonesia

plaster based powder filler greek Indonesia Plasters – Wacker Chemie AGWACKER offers resins and additives for dispersion-based, s...

Full range of BRU Vibrating Screens

The BRU Vibrating Screen is designed with durability and ease of use as a central focus. And, by improving performance and throughout, you can enjoy better throughput for your equipment. Usable in most applications, these screens come in a wide range of sizes, from 0.9m to 4.8m wide and up to 11.0m long. BRU Vibrating Screens are available in

Syntron Material Handling Vibrating Screens

Vibrating Screens From aggregates to coal, to , processing, pharmaceuticals, and other processes, Syntron® screen feeders are employed to scalp, separate, size, de-dust, and de-water bulk products.

Vibratory Screens General Kinematics

A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries. From the separation of heavy ores, molten hot castings and sand, to stone products and

Vibrating Screens Vibratory Screener Particle

The Prater Vibratory Screener uses a revolving eccentric motion generator that provides a circular motion with a vertical plane. High frequency coupled with a short amplitude (stroke) provides maximum screening efficiency.

Basic concepts of vibrating screens: What they are,

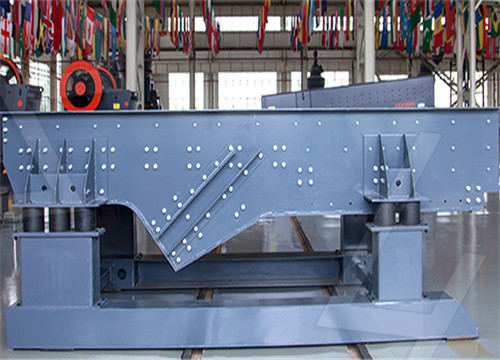

Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The screens serve to classify the different particles by size,

HEAVY DUTY INCLINED VIBRATING SCREENS Deister

And, Deister screens are backed by a follow-through parts and service policy without equal for Deister top management is personally interested in the continued profitable operation of every Deister screen. Deister Vibrating Screens have many outstanding features which are standard on each unit: TYPE HT AND BHT SIZES UP TO AND INCLUDING 16

NewUsed Vibrating Screens For Sale Surplus Record

Get email updates for newly added Vibrating Screens Create Alert 16" x 28" Martin #CD18.910, Stainless Steel Vibro-Screener, sgl.deck on stand, 35 KW, 230/460 V.vibro motor, #46046

Homemade Soil Screener/sifter : 11 Steps (with Pictures) Instructables

The screener is sized and designed to be loaded with a compact tractor, and the vibration is powered by a 6-1/2 HP gasoline engine but the design is just as applicable to a smaller (or larger) screener working on the same tire "suspension" idea and driven with either an electric motor or a larger gasoline engine.

Vibrating screen SKF

Vibrating screen. This example shows the bearing selection process applied to an application case in which a vibrating screen manufacturer is selecting the bearings for a new machine. Each step of the example is described in an expandable/drop-down section below. The steps in the example follow the sequence in the bearing selection process.

best Beneficiation equipment for Plaster Bengkulu

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

Linear vibrating screens LinaClass® Schenck Process

Linear vibrating screens are used in the pit, quarry, coal, ore and steel industries. The product family, under type designation LinaClass®, is based on a tried and tested modular system with standardised components, which are constantly optimised and expanded. Interesting for each user is the very broad range of sizes.

Industrial Vibrating Screens AdvantagesIts Uses

Basically, the Vibrating Screens are the pioneers in each prominent and notable industries, for a thorough refining and separation process. From processing to mining plants, this machine is at peak demand and make the entire process streamlined. Thus, driving efficiency at a cheaper cost.

Vibratory ScreenVibrating Sieves Russell Finex

Circular Vibrating ScreensVibratory Sieves Round Screeners |Russell Finex Machine Selector Find the right machine for you Home Our Products Check Screeners Russell Compact Sieve Check Screeners Russell Compact Sieve Compact Airlock Sieve Bag dump station 3in1 Sieve Compact Airswept Sieve Compact Self-Loading Sieve Finex 22" Sieve

Influence of Load Weight on Dynamic Response of Vibrating Screen Hindawi

2019年1月2日In a single test procedure, at first, the screen is in static state, after then the exciter begins to rotate at 53 Hz, so that obvious vibration occurs. After about 10 seconds, the exciter is suddenly powered off, leaving the screen vibration decaying freely until it

Syntron Material Handling Vibrating Screens

Vibrating Screens From aggregates to coal, to , processing, pharmaceuticals, and other processes, Syntron® screen feeders are employed to scalp, separate, size, de-dust, and de-water bulk products.

Full range of BRU Vibrating Screens

The BRU Vibrating Screen is designed with durability and ease of use as a central focus. And, by improving performance and throughout, you can enjoy better throughput for your equipment. Usable in most applications, these screens come in a wide range of sizes, from 0.9m to 4.8m wide and up to 11.0m long. BRU Vibrating Screens are available in

Basic concepts of vibrating screens: What they are,

Also called simply screens, a vibrating screen is formed by a vibrant chassis that supports in its interior one or several surfaces or elements of screening. The screens serve to classify the different particles by size,

Linear vibrating screens LinaClass® Schenck Process

Linear vibrating screens are used in the pit, quarry, coal, ore and steel industries. The product family, under type designation LinaClass®, is based on a tried and tested modular system with standardised components, which are constantly optimised and expanded. Interesting for each user is the very broad range of sizes.

MS SERIES INCLINED VIBRATING SCREENS mekaglobal

INCLINED VIBRATING SCREENS MEKA MS and MGS Series inclined vibrating screens combine high quality components with reliable de-sign and productive efficiency to give our custom-ers trouble-free, robust solutions for replacing old vibrating screens, adding additional production lines to their sites, or in new crushing and screen-ing plants.

HEAVY DUTY INCLINED VIBRATING SCREENS Deister

And, Deister screens are backed by a follow-through parts and service policy without equal for Deister top management is personally interested in the continued profitable operation of every Deister screen. Deister Vibrating Screens have many outstanding features which are standard on each unit: TYPE HT AND BHT SIZES UP TO AND INCLUDING 16

NewUsed Vibrating Screens For Sale Surplus Record

Category: Vibrating Screens Seller: Global Equipment International Location: Chalfont, PA Mfr: Dorr Oliver Model: DSM24 922001.008, One (1) used Dorr Oliver 24" (610mm) wide 120 degrees, 150 mesh, DSM screen. Stainless steel construction. With Goulds Mt 3" x 4" x 10" (76mm x 102mm x 254mm) stainless steelmore View Details Contact Seller

VIBRATING SCREENS Hawk Machinery

2014年7月22日TYPES OF VIBRATING SCREENS. Depending on your mining company’s needs, there is a vibrating screen for you at Hawk Machinery Melbourne. HI-SCALP VIBRATING SCREENS Hawk’s Hi

Homemade Soil Screener/sifter : 11 Steps (with Pictures) Instructables

The screener is sized and designed to be loaded with a compact tractor, and the vibration is powered by a 6-1/2 HP gasoline engine but the design is just as applicable to a smaller (or larger) screener working on the same tire "suspension" idea and driven with either an electric motor or a larger gasoline engine.

Vibrating screen SKF

Vibrating screen Vibrating screen This example shows the bearing selection process applied to an application case in which a vibrating screen manufacturer is selecting the bearings for a new machine. Each step of the example is described in an expandable/drop-down section below.

Industrial Vibrating Screens AdvantagesIts Uses

Basically, the Vibrating Screens are the pioneers in each prominent and notable industries, for a thorough refining and separation process. From processing to mining plants, this machine is at peak demand and

Stepwise shape optimization of the surface of a vibrating screen

2021年10月1日The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters. A simplified three-dimensional model of the vibrating screen, shown in Fig. 1, is established to reduce the complexity but realize the actual screening effect.Additionally, the sieving process in the

Types Of Vibrating Screens Introduction And

Vibratory screen is a rectangular single-, double-, and multi-layer, high-efficiency new screening equipment. Vibrating screen can be divided into inclined and horizontal screen. At present, the screens range in width

Syntron Material Handling Products

Belt Conveyor Idlers. Tapered Roller Bearing. Ball Bearing Idlers by Link-Belt. Composite Idler Rolls. Scale Quality Idlers. Catenary Idlers. Truss Frame. Extreme Service Idlers. Sure Align Tracker.