Animal Feed Crusher T H Hardness Iron Ore Crushing

Crusher an overview ScienceDirect Topics

The crushed material, which is around 15 cm in diameter obtained from the ore storage, is disposed as the final crusher product. The size is usually between 0.5 and 2 cm in

All crusher types for your reduction needs Metso Outotec

根据热度为您推荐•反馈

The six main steps of iron ore processing Multotec

The six main steps of iron ore processing When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We

Gyratory Crusher an overview ScienceDirect Topics

The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 1.5 m (for the largest equipment). This crusher can handle products with a Mohs hardness that

Crushing in Mineral Processing

2015年12月26日To feed a rod and/or ball milling circuit, you need to crush as follow: Crushers for large giant process plants >2,000 to 200,000 TPD using semi-autogenous mills only require primary crushing and are

700tph Iron Ore Crushing Plant Eastman Rock Crusher

2020年8月24日Iron is harder than most stones. According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is

Rock Crusher Eastman Rock Crusher

Which hammer crusher can crush iron ore (100TPH)? In this case, we recommend the use of a PCZ1308 heavy hammer crusher with a feed size of 930x650mm, the feed particle size is less than 600mm, the motor

Iron Ore CrushingGrinding Controls

2019年6月19日The Iron Ore Industry has perhaps seen more varied and drastic changes in its approach to crushing and grinding in the last 5 years than any of the other mineral industries. been eliminated because of

AMIT 135: Lesson 5 Crushing Mining Mill Operator

Primary Crushing The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can

Gyratory and Cone Crusher ScienceDirect

2016年1月1日feed distribution in the crushing area and the bulk density of the feed, 4. hardness of ore (work index), 5. A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the run-of-mine ore was 1000 mm. The required product size was less than 162 mm. Manufacturer’s data indicated that the

Challenges and opportunities in the iron ore crusher market

2019年8月8日The iron ore jaw crusher is a new generation of crushing machinery newly developed by mpl Machinery in combination with large-scale crushing machinery manufacturers at home and abroad. It specializes in the crushing of iron ore and overcomes the hardness and variable nature of iron ore materials.

The six main steps of iron ore processing Multotec

The six main steps of iron ore processing When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日Jaw crusher: feed diameter 0.1 to 1.5m; reduction ratio 5:1 to 10:1; capacity 1 to 300kg/s; Mohs hardness < 9 [reduction by compression]. Gyratory crusher: feed diameter 0.75 to 1.5m; reduction ratio 5:1 to 10:1, usually 8:1; capacity 140 to 1000 kg/s; Mohs hardness <9. More suitable for slabby feeds than jaw crusher. [reduction by

700tph Iron Ore Crushing Plant Eastman Rock Crusher

2020年8月24日Iron is harder than most stones. According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is subjected to primary rolling from large pieces to small pieces. The counter-attack crusher performs the second crushing, and finally the cone crusher controls the size of the ore particles.

Iron Ore CrushingGrinding Controls

2019年6月19日The Iron Ore Industry has perhaps seen more varied and drastic changes in its approach to crushing and grinding in the last 5 years than any of the other mineral industries. been eliminated because of the necessity of operating the rock hook or lowering the mantle when large chunks bridge the crusher cavity. Fine crushing,

ISO most popular price for mobile stone crusher of Crusher from

Quality ISO most popular price for mobile stone crusher find quality Crusher, CrusherCrusher from Henan Hongke Heavy Machinery Co., Ltd. of China Suppliers . penumatic type animal feed crusher and mixer hammer mill; Product Details. Condition: New: Type: AC Motor: Power(W): 75kw: Capacity(t/h): 50-80t/h: Place of Origin

Hard iron ore crushing, by KOBELCO GYRATORY CONE CRUSHER with YouTube

2021年5月19日#viral #viralvideos #ironore #ironorecrushing #ironoreprocessing #kobelco #kobelcogyratoryconecrusher #conecrusher #crusher #ironoremining #kobelcocrusher

Iron can crusher for crushing cans for iron and aluminum

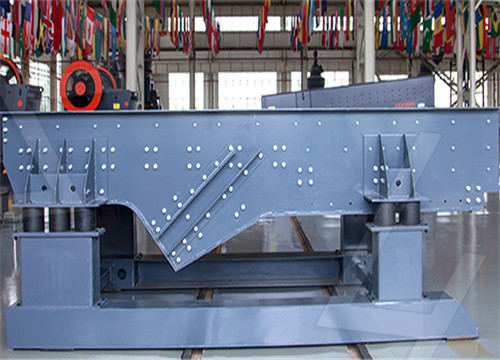

Quality Iron can crusher for crushing cans for iron and aluminum separation find quality Metal Crusher Machine, CrusherMetal Crusher Machine from Gongyi Derui Machinery Co., Ltd. of China Suppliers . Good Quality Heavy Hammer Crusher for Crushing All Kinds of Ores; Sand Ore and Coal Vibrating Feeder Machinery Used in

Iron ore crushing and screening process sbmmill.net

2022年8月3日Jaw crushers are generally used for head crushing in iron ore production operations, and gyratory crushers are often used in large mining operations. Jaw crusher is the most traditional and most stable and reliable primary crushing equipment and has the widest application range.

BIG AND HARD BOULDER CRUSHED BY 1600 TPH KOBELCO GYRATORY CONE CRUSHER

2022年2月15日big and hard boulder crushed by 1600 tph kobelco gyratory cone crusher ii iron ore crushing plant ii1600 tph kobelco gyratory cone crusher1 iron ore crushing...

All crusher types for your reduction needs Metso Outotec

Crushers are machines used to reduce the size of rocks, stones and ore. They are often utilized in aggregates production, construction material recycling and in mining operations. Metso Outotec offering covers different gyratory crushers, jaw crushers, cone crushers and impact crushers optimized for any size reduction need.

What is a Jaw Crusher? MEKA Crushing Equipment

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.) Obtaining the size or surface area required for the enrichment stage. In general, crushing is carried out in

Iron ore crushing system before and after improvement of the

2015年2月4日According hardness characteristics of iron ore, the jaw crusher specifications into 400 * 250 * 1200 600 jaw crusher, also from the 37kW motor replaced 18.5kW, the crusher inlet installation of a Secondly, when the jaw crusher for re-leveling, replacement of moving jaw assembly, leveling cement foundation; homemade small

Gyratory and Cone Crusher ScienceDirect

2016年1月1日feed distribution in the crushing area and the bulk density of the feed, 4. hardness of ore (work index), 5. A primary gyratory crusher was required to crush iron ore at the rate of 3000 t/h. The largest size of the run-of-mine ore was 1000 mm. The required product size was less than 162 mm. Manufacturer’s data indicated that the

The six main steps of iron ore processing Multotec

The six main steps of iron ore processing When iron ore is extracted from a mine, it must undergo several processing stages. Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage.

Rock Crushing Rule of Thumb Mineral ProcessingMetallurgy

2015年12月16日Jaw crusher: feed diameter 0.1 to 1.5m; reduction ratio 5:1 to 10:1; capacity 1 to 300kg/s; Mohs hardness < 9 [reduction by compression]. Gyratory crusher: feed diameter 0.75 to 1.5m; reduction ratio 5:1 to 10:1, usually 8:1; capacity 140 to 1000 kg/s; Mohs hardness <9. More suitable for slabby feeds than jaw crusher. [reduction by

700tph Iron Ore Crushing Plant Eastman Rock Crusher

2020年8月24日According to the traditional iron ore processing process, the jaw crusher is used for rough crushing, and the ore is subjected to primary rolling from large pieces to small pieces. The counter-attack crusher performs the second crushing, and finally the cone crusher controls the size of the ore particles. Minimize the loss of the crusher.

How to crush the very hard iron ore magnetite?

2023年2月1日Secondary crushing: The primary crushed ore is then fed into a cone crusher for further reduction. Grinding: The crushed ore is then ground into a fine powder in a ball mill or other grinding mill.

Crusher Discharge T10 PSD Particle Size Distribution Crushing

Also t10 is related to reduction ratio for the same ore Fig 6.6. All good. I'm trying simulating a two stage iron ore crushing circuit to produce a maximum of lump and all I know is that the top size of the shot rock is 600 mm and the Crushing Work Index is 8-9 kW-h/tonne. Let's say a very similar ore is giving a lump to fines split of 40:60.

Hard iron ore crushing, by KOBELCO GYRATORY CONE CRUSHER with YouTube

2021年5月19日#viral #viralvideos #ironore #ironorecrushing #ironoreprocessing #kobelco #kobelcogyratoryconecrusher #conecrusher #crusher #ironoremining #kobelcocrusher

BIG AND HARD BOULDER CRUSHED BY 1600 TPH KOBELCO GYRATORY CONE CRUSHER

2022年2月15日big and hard boulder crushed by 1600 tph kobelco gyratory cone crusher ii iron ore crushing plant ii1600 tph kobelco gyratory cone crusher1 iron ore crushing...

Iron can crusher for crushing cans for iron and aluminum

Quality Iron can crusher for crushing cans for iron and aluminum separation find quality Metal Crusher Machine, CrusherMetal Crusher Machine from Gongyi Derui Machinery Co., Ltd. of China Suppliers . Good Quality Heavy Hammer Crusher for Crushing All Kinds of Ores; Sand Ore and Coal Vibrating Feeder Machinery Used in

ISO most popular price for mobile stone crusher of Crusher from

Quality ISO most popular price for mobile stone crusher find quality Crusher, CrusherCrusher from Henan Hongke Heavy Machinery Co., Ltd. of China Suppliers . penumatic type animal feed crusher and mixer hammer mill; Product Details. Condition: New: Type: AC Motor: Power(W): 75kw: Capacity(t/h): 50-80t/h: Place of Origin

Rock Crusher Eastman Rock Crusher

Rock Crushing Equipment for Sale jaw crusher Capacity: 1-1120t/h Feed Size: 100-1200mm Output Size: 10-350mm impact crusher Capacity: 10-350t/h Feed Size: 100-500mm Output Size: 10-80mm hammer crusher Capacity: 1-75t/h Feed Size: 0-400mm Output Size: 0-15mm HP cone crusher Capacity: 70-1200t/h Feed Size: 5-350mm

Iron ore crushing system before and after improvement of the

2015年2月4日According hardness characteristics of iron ore, the jaw crusher specifications into 400 * 250 * 1200 600 jaw crusher, also from the 37kW motor replaced 18.5kW, the crusher inlet installation of a Secondly, when the jaw crusher for re-leveling, replacement of moving jaw assembly, leveling cement foundation; homemade small

What is a Jaw Crusher? MEKA Crushing Equipment

The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7. Hydraulic Cylinder 8. Toggle Plate 9. Swing Jaw 10. Discharge 11. Fixed Jaw Jaw Crusher Parts G: Gape width, b: maximum feed size,

Ore, Mineral,Slag Crusher Stedman Machine Company

Mineral RocksOre Crushing Machines Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining application. Whether you are processing iron ore, coal, rock, salt, chips, or clay to name a

- How Does Impact Mining Mill Work

- 弹簧圆锥破碎机生产商

- PE-600X900鄂式破碎机

- Chris Custom Loud Crusher Local 60s Group From Stockton

- Professional Super Quality Widely Used Spiral Classifying Machine

- Mtw Milling Machine Lsx Sand Washing Machine Mobile Jaw Crusher

- Stone Mining Mill With Low Price

- 共和高速公路石料生产线

- 矿石破碎机生产线的生产厂家

- 制作白灰机器价格

- 陕西思宇信息技术

- 灰钙粉在腻子粉中的作用

- XP-250×1200破碎机

- 湖南采石场分布

- 镜面速度除雾器