Construction Of Vibrating Screens Units

Vibrating Screens Vibramech

Vibramech screens are equipped with vibrator motor, geared exciter or oscillator drives, and are available in single-, double- or triple-deck configuration. The range of screening media includes polyurethane

LINATEX® Vibrating Screens

Linatex® vibrating screens have a reputation of being quality machines providing exceptional screen process performance for our customers in a wide range of

Syntron Material Handling Vibrating Screens

These four ruggedly constructed vibrating screen models provide medium and heavy-duty service screening for a wide range of materials in the coal, aggregate, asphalt, pulp and , and chemical handling industries.

Vibrating Screen Working Principle Mineral Processing

IntroductionNamingMechanismApplicationsPurposeCauseUseSpecificationsSafetyOperationAssessmentCriticismsAnalysisExampleAdvantagesConstructionTypesDesign

The Vibrating Screen is available in single and multiple deck units for floor mounting or suspension. The side panels are equipped with flanges containing precision punched bolt holes so that an additional deck may be added in the future by merely bolting the new deck either on the top or the bottom of the original deck. The advantage of this featu...

Vibratory Screens General Kinematics

GK Home > Vibratory Screens A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries. From the separation of heavy ores, molten hot castings and sand, to

Vibrating Screens Parker Plant

The e is a free floating screen, effectively isolated by its springs from the support structure. For transit, the screen is restrained in its angled travelling position by reusable clamp plates (travel brackets) simply

Home Conn-Weld

Conn-Weld’s Horizontal Screens have proven performance in every application. Wide-body H-Beam construction with twin H-Beams at feed and discharge Heavy-duty welded

Ore, RockAggregate Screening (Complete Guide)

2016年6月20日Freely vibrating screens. By freely vibrating screens one means screens that are supported on springs, and the box is vibrated by a vibrating mechanism (also called an exciter) which vibrates the

Linear vibrating screener, Linear vibrating screening unit

construction screener Enduron® process linear vibrating centrifugal Featuring a stress-relieved, all-bolted construction using locking bolts to ensure structural integrity, our Enduron® horizontal screens deliver

LINATEX® Vibrating Screens

Linatex® vibrating screens have a reputation of being quality machines providing exceptional screen process performance for our customers in a wide range of applications. All Linatex vibrating screens are supplied as linear motion units. Linear motion allows for screens with a low headroom requirement and less pegging of screen media when

Vibrating Screens Vibramech

Vibramech screens are equipped with vibrator motor, geared exciter or oscillator drives, and are available in single-, double- or triple-deck configuration. The range of screening media includes polyurethane

Vibrating Screens Parker Plant

Parker have been designing and manufacturing vibrating aggregate grading screens for over 50 years and its e range of machines is at the forefront of the need to provide an efficient screen with features ensure

HEAVY DUTY INCLINED VIBRATING SCREENS Deister

Deister Vibrating Screen is the exclusive “unitized” vibrating mechanism mounted on top of the vibrating frame. The entire vibrating mechanism is a precision constructed, jig assembled unit, which incorporates all the advantages of a two-bearing vibrating mechanism and runs in a bath of oil with internal and external labyrinth seals to

SWECO Fusion Vibrating Screens / Vibration Screens

SWECO Screens, Fusion and Fusion Plus. Contact SWECO Americas 859-371-4360 • Europe 32 67 893434 • Asia 65 6762 1167. Aftermarket.

Vibrating screen monitored safelyeasily Schaeffler medias

Construction materials manufacturer Holcim was seeking a condition monitoring solution for the vibrating screens in its cement plant in Hermosillo, Mexico. Specifically, Holcim wanted a solution that would more effectively predict and prevent catastrophic bearing failures. Monitored units: Vibrating screen bearing: Monitored operating

Vibrating Screen NSK Europe

Key Facts Manufacturer of Vibrating Screen Machines Severe environment requiring special bearings Pressure to reduce manufacturing costs NSK employed special vibratory screen bearings NSK bespoke design for supply of complete housing, bearing and sealing solution Resultant bolt on complete solution Reduced need for complex fitting Vibrating

IS 12213 (1987): Code for mechanical vibrating screens

UDC 621-928.235 IS:12213-1987 Indian Standard CODE FOR MECHANICAL VIBRATING SCREENS . 1. Scope Covers mechanical vibrating screens used for, screening the material of various grain sizes. 1.1 The standard screen sizes shall be in accordance with IS : 2405-1980 ‘Specification for industrial sieves’. 2. Nomenclature For the purpose of this

Syntron Material Handling Vibrating Screens

These four ruggedly constructed vibrating screen models provide medium and heavy-duty service screening for a wide range of materials in the coal, aggregate, asphalt, pulp and , and chemical handling industries.

ultrasonic vibrating screen on sale China quality ultrasonic

We find 296 products about ultrasonic vibrating screen from 66 manufacturerssuppliers. high accurency vibrating screen separator, separating effect vibrating sieve ultrasonic vibrating screen $1,890 $8,600 / Set

Derrick Corporation Solids Control and Fine Wet /

Derrick Corporation has once again redefined high capacity, high efficiency, fine particle wet screening with the introduction of the SuperStack. With 8 decks operating in parallel and innovative Front-to

Compact Screening Plant Screen Machine

The Scalper 77C is a patented, heavy-duty screening plant that is designed to screen soils and aggregates. It works best when paired with a 1 to 2 yard (.9m 1.75m) front-end loader. View our Scalper 77C Screening Plant. Browse types of

Exciter MechanismsVibration Types MEKA

Circular Stroke Exciter Mechanisms. Vibration is transmitted to the screen deck by the exciter (vibrator) assembly. The vibrator assembly comprises eccentric masses mounted on the exciter shaft. The shaft is supported on either two or four (depending on the capabilities of the bearing and housing design) vibration screen duty self-aligning

Vibrating Screens Vibramech

Vibramech vibrating screens are custom designed for client needs and cover a vast range of sizes and unique process applications. Our screen design makes use of Finite Element Method and Strain Gauge Analysis

HEAVY DUTY INCLINED VIBRATING SCREENS Deister

Deister Vibrating Screen is the exclusive “unitized” vibrating mechanism mounted on top of the vibrating frame. The entire vibrating mechanism is a precision constructed, jig assembled unit, which incorporates all the advantages of a two-bearing vibrating mechanism and runs in a bath of oil with internal and external labyrinth seals to

SWECO Fusion Vibrating Screens / Vibration Screens

SWECO Screens, Fusion and Fusion Plus. Contact SWECO Americas 859-371-4360 • Europe 32 67 893434 • Asia 65 6762 1167. Aftermarket.

Incline Vibrating Screen Mineral Equipment Sepro

Sepro Vibrating Screens are synonymous with high efficiency, reliable classification and dewatering capabilities. Sepro offers high capacity vibrating screens available in a variety of models and sizes to suit

Compact Screening Plant Screen Machine

The Scalper 107D is a patented, wheeled, heavy-duty vibratory screener that is perfect for soils, scrap and construction and demolition debris processing utilizing a 3 to 5 yard (2.5m 4m) front-end loader. View our

Vibrating screen monitored safelyeasily Schaeffler medias

Construction materials manufacturer Holcim was seeking a condition monitoring solution for the vibrating screens in its cement plant in Hermosillo, Mexico. Specifically, Holcim wanted a solution that would more effectively predict and prevent catastrophic bearing failures. Monitored units: Vibrating screen bearing: Monitored operating

Vibrating Screens

The e is a free floating screen, effectively isolated by its springs from the support structure. For transit, the screen is restrained in its angled travelling position by reusable clamp plates (travel brackets) simply bolted across the spring units. Platforms. Optional, open mesh platforms on one or both sides of the machine provide easy

Linear vibrating screener, Linear vibrating screening

Units are mounted horizontally, Compare this product Remove from comparison tool. Very low maintenance Heavy-duty construction, permanent lubrication, and easy access to sieves for cleaning or

Vibrating Screen NSK Europe

Key Facts Manufacturer of Vibrating Screen Machines Severe environment requiring special bearings Pressure to reduce manufacturing costs NSK employed special vibratory screen bearings NSK bespoke design for supply of complete housing, bearing and sealing solution Resultant bolt on complete solution Reduced need for complex fitting Vibrating

ultrasonic vibrating screen on sale China quality ultrasonic

We find 296 products about ultrasonic vibrating screen from 66 manufacturerssuppliers. high accurency vibrating screen separator, separating effect vibrating sieve ultrasonic vibrating screen $1,890 $8,600 / Set

Circle-throw vibrating machine Wikipedia

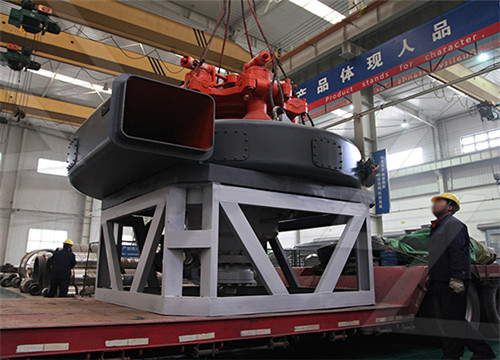

The standard unit is a single-shaft, double-bearing unit constructed with a sieving box, mesh, vibration exciter and damper spring. The screen framing is steel side plates and cross-members that brace static and dynamic forces. At the center of the side plates, two roller bearings with counterweights are connected to run the drive.

Derrick Corporation Solids Control and Fine Wet /

Derrick Corporation has once again redefined high capacity, high efficiency, fine particle wet screening with the introduction of the SuperStack. With 8 decks operating in parallel and innovative Front-to

Exciter MechanismsVibration Types MEKA

Circular Stroke Exciter Mechanisms. Vibration is transmitted to the screen deck by the exciter (vibrator) assembly. The vibrator assembly comprises eccentric masses mounted on the exciter shaft. The shaft is supported on either two or four (depending on the capabilities of the bearing and housing design) vibration screen duty self-aligning