Calcite Ore Flotation Machine Price In Western Sahara

Calcite in froth flotation A review ScienceDirect

2022年7月1日The low selectivity for the calcite flotation separation is mainly due to its semi-solubility in water. Calcite solubility can develop similar surface properties for its

An Overview of Calcite Recovery by Flotation

An Overview of Calcite Recovery by Flotation Priyanka Dhar 1Maria Thornhill 1Hanumantha Rao Kota 1 Received: 13 April 2020 /Revised: 28 July 2020 /Accepted: 30

Minerals Free Full-Text Selective Flotation of Calcite from

2016年10月26日A feed ore contains 39.97% fluorite and 17.87% calcite, with the other main components being 36.69% micaceous minerals and 3.35% limonite. The grinding

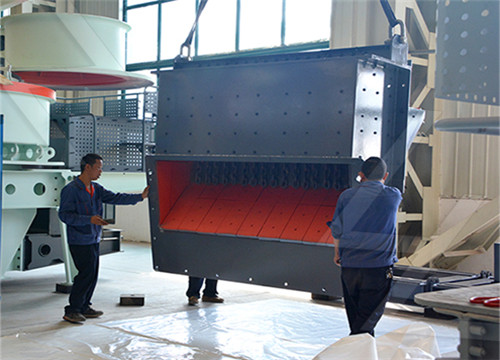

Flotation Machines Mineral Processing Machine

The flotation machine is mechanical equipment for realizing the froth flotation process and separating target minerals from ore. At present nearly 2 billion tons of ore in the world

Calcite Processing by Flotation for Beneficiation

2016年4月12日The Calcite Flotation Flowsheet In all cement plants it is necessary to crush the lime-rock and grind it down to the desired fineness for the kiln feed. In some

An Overview of Calcite Recovery by Flotation Semantic Scholar

In general, precipitated calcium carbonate (PCC) is used as a mineral filler in stone industries; while natural calcite (CaCO 3 ) ore is also suitable for industrial use if it is a

Flotation separation of scheelite from calcite using mixed

Fig. 3 presents the flotation recoveries of scheelite and calcite as a function of pH in the presence of 50 mg/L oxidized paraffin soap and 200 mg/L BHA, respectively. Both

Flotation Plant with Low Price and High performance

125 TPH feldspar flotation process in India. The raw ore of a feldspar mine in India contains 4.37% of K 2 O, 3.38% of Na 2 O, 30.48% of Fe 2 O, 77.56% of SiO 2, 12.13% of Al 2 O

Find A Wholesale flotation copper concentrator plant

Factory low price sale Gold, copper, zinc, lead, silver processing plant air flotation machine for Copper Ore Processing Plant $15,000.00-$80,000.00 / set 1 set (Min.

An Overview of Calcite Recovery by Flotation ResearchGate

REVIEW An Overview of Calcite Recovery by Flotation Priyanka Dhar 1Maria Thornhill 1Hanumantha Rao Kota 1 Received: 13 April 2020 /Revised: 28 July 2020 /Accepted: 30 July 2020 # The Author

Calcite Prices: Latest Price, Pricing, News, Market Analysis

Procurement Resource provides latest prices of Calcite. Each price database is tied to a user-friendly graphing tool dating back to 2014, which provides a range of functionalities: configuration of price series over user defined time period; comparison of product movements across countries; customisation of price currencies and unit; extraction of

Minerals Free Full-Text Selective Flotation of Calcite from

2016年10月26日An XFG flotation machine ( Figure 2) (Exploring Machinery Plant, Changchun, China) with a 40 mL cell was used for flotation tests of single mineral and mixed binary minerals, while a 1.5 L cell was used

Purification of High-grade Calcite Ore by Flotation with Alkyl

2018年9月17日The feasibility of sulphide flotation from calcite by this cationic collector has been initially judged from Hallimond flotation and zeta potential on pure mineral systems and the results illustrate the removal of sulphide from calcite ore at

Flotation Machines Mineral Processing MachineSolutions

The flotation machine is composed of single or multiple flotation cells, by agitating and inflating the chemical reagent treated slurry, some mineral ore particles are adhered to the foam and float up, and then be scraped out, while the rest remains in the slurry. Types of flotation machine

An Overview of Calcite Recovery by Flotation Springer

An Overview of Calcite Recovery by Flotation Priyanka Dhar1Maria Thornhill1Hanumantha Rao Kota1 Received: 13 April 2020 /Revised: 28 July 2020 /Accepted: 30 July 2020 impurities from calcite ore. However, there are few Nordic high-grade calcite ore deposits with sulphides and graphite as impurities. Generally, different kinds of

Effect of Fluoride Ion on the Separation of Fluorite from Calcite

2021年10月28日The micro-flotation experiments of single mineral and artificial mixed ore were carried out using an RK/FGC5-35 (Wuhan New Materials Industry Park, Wuhan, China) flotation machine at room temperature. The stirring speed of the flotation machine was 1600 rpm, and the airflow rate was 0.04 m 3 /h.

Flotation behavior and mechanism of phenylpropenyl

2021年10月1日As for the flotation experiments of calcite, PHA could obtain the maximum recovery at 44% with pulp pH 7, and the recovery could reach at 92% (NaOL) or 43.5% (BHA). Download : Download high-res image (274KB) Download : Download full-size image Fig. 5. Effect of pulp pH on flotation recovery of smithsonite (a) and calcite (b)

Flotation Plant with Low Price and High performance Fote

125 TPH feldspar flotation process in India. The raw ore of a feldspar mine in India contains 4.37% of K 2 O, 3.38% of Na 2 O, 30.48% of Fe 2 O, 77.56% of SiO 2, 12.13% of Al 2 O 3. Our customer expects to recover the feldspar in it. Fote adopts an acidic fluorine-free flotation process to process the ore.

Find A Wholesale flotation copper concentrator plant price

Factory low price sale Gold, copper, zinc, lead, silver processing plant air flotation machine for Copper Ore Processing Plant $15,000.00-$80,000.00 / set 1 set (Min. order) CN Shanghai Yingyong Machinery Co., Ltd. 5YRS 4.7 ( 4) Contact supplier 1 / 6 Flotation Copper Concentrator Plant Plant Copper Refinery Plant with Copper Ore Production Line

An Overview of Calcite Recovery by Flotation Semantic Scholar

In general, precipitated calcium carbonate (PCC) is used as a mineral filler in stone industries; while natural calcite (CaCO 3 ) ore is also suitable for industrial use if it is a finely ground high-grade material. Naturally, calcite is found in the form of high- or low-grade ores and it is one of the most widely distributed industrial minerals on the earth’s crust.

Manganese Ore Processing Mineral ProcessingMetallurgy

2016年4月27日Manganese Ore Concentration by Flotation. The slime fraction of the ore overflowed by the hydraulic classifier and by the rod-mill spiral classifier is thickened in a Spiral Rake Tray Thickener for treatment by flotation. The flotation circuit is designed to treat three classes of manganese ores. Those ores with a high calcite gangue.

Flotation separation of scheelite from calcite using mixed

Fig. 3 presents the flotation recoveries of scheelite and calcite as a function of pH in the presence of 50 mg/L oxidized paraffin soap and 200 mg/L BHA, respectively. Both scheelite and calcite showed good flotation in the pH region from 7 to 12 when using OPS as collector. The high recovery of both minerals in the basic region is attributed to

Flotation separation of fluorite from calcite using polyaspartate

2018年5月1日Therefore, the flotation separation of fluorite from calcite was mainly studied. Table 1. Chemical analysis results of the real ore samples/%. The main reagents used in this study were as follows: collector sodium oleate (NaOL), pH regulators HCl and NaOH, and depressant PASP. The chemical structure and IR spectrum of PASP are

An Overview of Calcite Recovery by Flotation ResearchGate

An Overview of Calcite Recovery by Flotation Priyanka Dhar 1Maria Thornhill 1Hanumantha Rao Kota 1 Received: 13 April 2020 /Revised: 28 July 2020 /Accepted: 30 July 2020

Calcite Prices: Latest Price, Pricing, News, Market Analysis

Calcium carbonate industrial grade price ex-Mumbai was estimated at 208.89 USD/MT in September and finished at 165.05 USD /MT for Industrial grade. Europe Throughout Q1 2021, demand remained steady across Europe, driven by downstream sectors such as construction and medicine.

An Overview of Calcite Recovery by Flotation Springer

An Overview of Calcite Recovery by Flotation Priyanka Dhar1Maria Thornhill1Hanumantha Rao Kota1 Received: 13 April 2020 /Revised: 28 July 2020 /Accepted: 30 July 2020 impurities from calcite ore. However, there are few Nordic high-grade calcite ore deposits with sulphides and graphite as impurities. Generally, different kinds of

Purification of High-grade Calcite Ore by Flotation with Alkyl

2018年9月17日The feasibility of sulphide flotation from calcite by this cationic collector has been initially judged from Hallimond flotation and zeta potential on pure mineral systems and the results illustrate the removal of sulphide from calcite ore at

Froth flotation process and its application Wiley Online

2021年2月5日Flotation machines[5] There are 40 different types of flotation cells that are being used all over the world. Most of them are represented by three main types. 2.1.1. the ore and the hydrophobic part will be away from it (figure 5). Hyd ro ph il c a t Hydrophobic part + Ore Figure 5: Schematic representation of ore

An Overview of Calcite Recovery by Flotation Semantic Scholar

In general, precipitated calcium carbonate (PCC) is used as a mineral filler in stone industries; while natural calcite (CaCO 3 ) ore is also suitable for industrial use if it is a finely ground high-grade material. Naturally, calcite is found in the form of high- or low-grade ores and it is one of the most widely distributed industrial minerals on the earth’s crust.

Effect of Fluoride Ion on the Separation of Fluorite from Calcite

2021年10月28日The micro-flotation experiments of single mineral and artificial mixed ore were carried out using an RK/FGC5-35 (Wuhan New Materials Industry Park, Wuhan, China) flotation machine at room temperature. The stirring speed of the flotation machine was 1600 rpm, and the airflow rate was 0.04 m 3 /h.

Flotation Plant with Low Price and High performance Fote

125 TPH feldspar flotation process in India. The raw ore of a feldspar mine in India contains 4.37% of K 2 O, 3.38% of Na 2 O, 30.48% of Fe 2 O, 77.56% of SiO 2, 12.13% of Al 2 O 3. Our customer expects to recover the feldspar in it. Fote adopts an acidic fluorine-free flotation process to process the ore.

Flotation Machines Mineral Processing MachineSolutions

The flotation machine is composed of single or multiple flotation cells, by agitating and inflating the chemical reagent treated slurry, some mineral ore particles are adhered to the foam and float up, and then be scraped out, while the rest remains in the slurry. Types of flotation machine

Flotation separation of scheelite from calcite using mixed

Fig. 3 presents the flotation recoveries of scheelite and calcite as a function of pH in the presence of 50 mg/L oxidized paraffin soap and 200 mg/L BHA, respectively. Both scheelite and calcite showed good flotation in the pH region from 7 to 12 when using OPS as collector. The high recovery of both minerals in the basic region is attributed to

Manganese Ore Processing Mineral ProcessingMetallurgy

2016年4月27日Manganese Ore Concentration by Flotation. The slime fraction of the ore overflowed by the hydraulic classifier and by the rod-mill spiral classifier is thickened in a Spiral Rake Tray Thickener for treatment by flotation. The flotation circuit is designed to treat three classes of manganese ores. Those ores with a high calcite gangue.

Flotation separation of fluorite from calcite using polyaspartate

2018年5月1日Therefore, the flotation separation of fluorite from calcite was mainly studied. Table 1. Chemical analysis results of the real ore samples/%. The main reagents used in this study were as follows: collector sodium oleate (NaOL), pH regulators HCl and NaOH, and depressant PASP. The chemical structure and IR spectrum of PASP are

Selective Flotation of Calcite from Fluorite: A Novel Reagent

2016年10月26日The flotation experiments were carried out in an XFG-type flotation machine [19, [35][36][37][38] at a spindle speed of 1850 rpm. In each flotation experiment, a single-mineral sample (2.00 g) or

Used flotation plant Machinio

Click to Request Price. Physical chemical plants flotation water treatment plant. NEW. Flotation machine can be used for many ore beneficiation . It is subject to coarse separation, swept separation, fine separation and flotation, so the useful ore are reclaimed. Application: Metal ore such as gold...