Design Consultant For Single Toggle Jaw Crusher

Optimisation of the swinging jaw design for a single

2022年9月20日This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for

Industrial Solutions Jaw crushers ThyssenKrupp

Single-toggle jaw crushers are characterized by a high throughput rate, simple design, low weight and low space requirement. Flywheel Eccentric shaft with bearing Back wall

Jaw Crushers JW Series

Cedarapids® JW Series single toggle jaw crushers have been designed using our long experience in manufacturing machines to handle exceptionally heavy and continuous

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A

2017年6月30日This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the

Jaw Crushers PR Engineering

The Birdsboro Buchanan Jaw Crusher was redesigned by PR Engineering to accommodate a more modern fabricated design versus the older, casted crushers. Over the years, the

Difference Between SingleDouble Toggle Jaw Crusher

2014年9月20日Double Toggle Jaw Crusher. In contrast, the single toggle jaw crusher has fewer shafts and bearings and only one toggle which goes from the bottom of the swinging jaw to a fixed point at the

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic

Journal of Engineering, Design and Technology

kinematical model of the single toggle jaw crusher is established, and then, a kinematicalanalysisofthemodel,basedonthevectorloopclosuremethod(Erdmanand

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE

2017年6月30日Productivity of the crusher can be improved upon by increasing the eccentricity of the eccentric shaft, use of reversible jaws, bush bearing and easily

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022年9月20日This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing. During the crushing process, large and non-evenly distributed impact forces occur,

Jaw Crushers JW Series

these durable crushers utilize heavy duty components for optimum operation and long life. Typical applications for our single toggle jaw crushers are in mining, quarrying and recycling. The jaw is designed to crush in the most arduous applications with the hardest rock. Simple installation Adaptable mounting arrangement suitable for

ST60 Jaw Crusher MPS

The ® Jaques Single Toggle jaw crushers feature large gape feed openings, high production and low operating costs. These rugged machines are manufactured with heavy duty parts for constant operation and long life. Typical applications for our single-toggle jaw crushers are in mining, quarrying and recycling.

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Blake crusher is of two types, viz: single toggle and double toggle jaw crushers. The single toggle swing jaw is suspended on the eccentric shaft, which allows a lighter, more compact design than with the double toggle crusher [10]. Moreover, the single toggle crusher is taking over most new applications due to lower cost and

How does a Single Toggle Jaw Crusher work?

Single Toggle Jaw Crushers are Easy to Run Follow these simple rules to keep crushing Maintain Cleanliness Check oil level frequently and make sure it is not contaminated When changing the oil, make sure to remove

Journal of Engineering, Design and Technology

Journal of Engineering, Design and Technology Analysis of the single toggle jaw crusher kinematics Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi Article information: To cite this document: Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi,(2015),"Analysis of the single

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

2017年6月30日A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine the time and energy required to crush the material. Economy of the crushing process is partly dependent on the angle of nip. Productivity of

Jaw plate kinematical analysis for single toggle jaw crusher design

DOI: 10.1049/CP: Corpus ID: ; Jaw plate kinematical analysis for single toggle jaw crusher design @inproceedings{Cao2006JawPK, title={Jaw plate kinematical analysis for single toggle jaw crusher design}, author={Jinxi Cao and Xingfu Rong and Shi Chun Yang}, year={2006} }

Single Toggle Jaw Rock Crusher GrabCAD

2020年10月28日Single Toggle Jaw Rock Crusher Master.STEP. step. October 28th, 2020 _085627.jpg. jpg. October 28th, 2020 _092017.jpg. jpg. The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users.

Single Toggle Jaw Crusher Sagarmatha Industries

Call Us: +977-051-520572; Email:info@sagarmathaind; SAGARMATHA INDUSTRIES. Home; Company Profile; Our Products. Single Toggle Jaw Crusher

Analysis of the single toggle jaw crusher kinematics Emerald

2015年5月5日Design/methodology/approach. The swing jaw drive mechanism of a single toggle jaw crusher is modelled as a planar crank and rocker mechanism with the swing jaw as the coupler link. Starting with the vector loop closure equation for the mechanism, equations of the position, velocity and acceleration of any given point in the swing jaw

CJ411 Single-Toggle Jaw Crusher For High Production

CJ411 single-toggle jaw crusher is engineered for even the toughest mining applications thanks to its heavy-duty design. Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost. Email us Request a quote.

Jaw Crusher ScienceDirect

2016年1月1日Design of Jaw Crushers Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of the plates are made of hardened steel. Both plates could be flat or the fixed plate flat and the moving plate convex. The surfaces of both plates could be plain or corrugated.

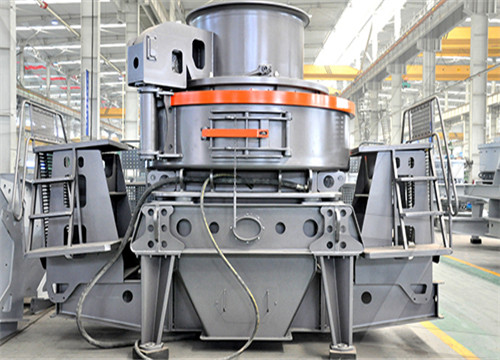

Single Toggle Jaw Crusher With Unique Benefits mpl

The single-toggle jaw crusher is mainly composed of a frame, a jaw plate, two side guard plates, a toggle plate, a flywheel, a shaft, and a regulating device. Its frame is cast in sections and then bolted together. The casting process is complex.

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022年9月20日This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing. During the crushing process, large and non-evenly distributed impact forces occur,

Jaw Crushers JW Series

these durable crushers utilize heavy duty components for optimum operation and long life. Typical applications for our single toggle jaw crushers are in mining, quarrying and recycling. The jaw is designed to crush in the most arduous applications with the hardest rock. Simple installation Adaptable mounting arrangement suitable for

ST60 Jaw Crusher MPS

The ® Jaques Single Toggle jaw crushers feature large gape feed openings, high production and low operating costs. These rugged machines are manufactured with heavy duty parts for constant operation and long life. Typical applications for our single-toggle jaw crushers are in mining, quarrying and recycling.

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022年9月20日This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the

How does a Single Toggle Jaw Crusher work?

Single Toggle Jaw Crushers are Easy to Run Follow these simple rules to keep crushing Maintain Cleanliness Check oil level frequently and make sure it is not contaminated When changing the oil, make sure to remove

Journal of Engineering, Design and Technology

Journal of Engineering, Design and Technology Analysis of the single toggle jaw crusher kinematics Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi Article information: To cite this document: Moses Frank Oduori Stephen Mwenje Mutuli David Masinde Munyasi,(2015),"Analysis of the single

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

2017年6月30日A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to be crushed are intrinsic properties that determine the time and energy required to crush the material. Economy of the crushing process is partly dependent on the angle of nip. Productivity of

Jaw plate kinematical analysis for single toggle jaw crusher design

DOI: 10.1049/CP: Corpus ID: ; Jaw plate kinematical analysis for single toggle jaw crusher design @inproceedings{Cao2006JawPK, title={Jaw plate kinematical analysis for single toggle jaw crusher design}, author={Jinxi Cao and Xingfu Rong and Shi Chun Yang}, year={2006} }

Single Toggle Jaw Rock Crusher GrabCAD

2020年10月28日Single Toggle Jaw Rock Crusher Master.STEP. step. October 28th, 2020 _085627.jpg. jpg. October 28th, 2020 _092017.jpg. jpg. The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users.

Single Toggle Jaw Crusher Sagarmatha Industries

Call Us: +977-051-520572; Email:info@sagarmathaind; SAGARMATHA INDUSTRIES. Home; Company Profile; Our Products. Single Toggle Jaw Crusher

CJ411 Single-Toggle Jaw Crusher For High Production

CJ411 single-toggle jaw crusher is engineered for even the toughest mining applications thanks to its heavy-duty design. Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost. Email us Request a quote.

Analysis of the single toggle jaw crusher kinematics Emerald

2015年5月5日Design/methodology/approach. The swing jaw drive mechanism of a single toggle jaw crusher is modelled as a planar crank and rocker mechanism with the swing jaw as the coupler link. Starting with the vector loop closure equation for the mechanism, equations of the position, velocity and acceleration of any given point in the swing jaw

Metso ® C Series™ jaw parts

designed for use with a two-piece jaw die, while the smaller jaw crushers used a one-piece jaw die design. Benefits of one-piece jaw die design • Faster jaw die replacement less down-time On single toggle jaw crushers, the fixed jaw die may wear at a faster rate. The table on the right shows the indicative lifetime of the