Process Flow Chart For Iron Ore Dry Grinding Process

Process flow sheet for Pelletization using dry grinding

Iron ore concentrates have been generated utilizing the conventional beneficiation process and also by the approach of reduction roasting-magnetic separation. The Fe contents of the hematite...

IR1-3 Ore Processing

Section 1.4.3.3.2 of the EIS 2012 states that iron ore concentrate may be produced based on market applies conventional grinding and flotation processes will produce a

Case Study of Dry HPGR Grinding and Classification in Ore

2019年2月5日Dry HPGR processing is gathering interest from industries that are operating in areas where water scarcity or process conditions

Fine Dry Grinding of Iron Ore for Pelletizing

Design Considerations For Selecting A Grinding SystemOpen vs. Closed Circuit Dry GrindingEffect on Pellet QualityOperating Considerations

The Hamersley pellet plant flowsheet consists of: three variable speed conveyors which feed nominal minus ¼ inch ore to three 14′-0″ diameter x 38′ x 6″ long, grate discharge ball mills. The mill discharge, which is the final product, is discharged through an airslide system either to a cement-type vertical ore cooler and then to the product convey...

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore

Iron ore grinding process,process design for grinding

2020年9月16日The ore can be ground from 20-25 mm to about 3 mm at a time. The open-circuit grinding process is simple, the production capacity is large, no grading and

process flow chart for iron ore dry grinding process

process flow chart for iron ore dry grinding process Flowchart Of Kaolin Beneficiation Process dry grind process flow sheet for feldspar mining flow chart of types of

Iron Ore Processing Flowsheet Grinder Process

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing. The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the

Mineral Processing an overview ScienceDirect Topics

A holistic conceptual flow diagram showing the journey from run-of-mine ore to concentrate, and ultimately to metal production at 99.99% grade. Figure 13.54 . A complete flow

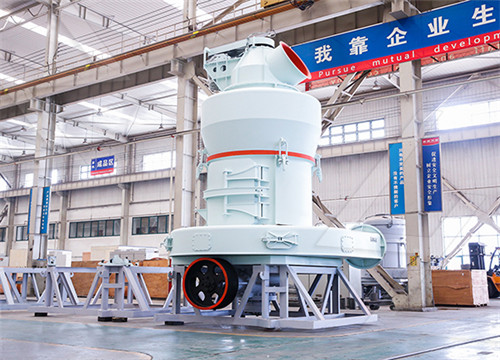

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日The grinding parts of a Loesche mill (Fig. 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms

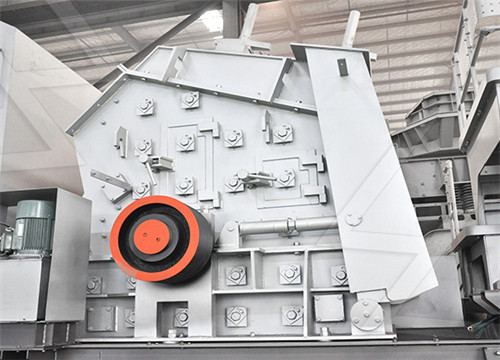

High-Pressure Grinding Roller Presses for Minerals

The process takes place between two counter- rotating rollers, whereby the ore is choke-fed between the rollers. The feed material is compressed from the bulk density to 70–85 % of the real density and the individual particles are exposed to very high pressure.

Case Study of Dry HPGR Grinding and Classification

2019年2月5日This publication summarizes some of the features and experiences with dry HPGR processing. A descriptive iron ore case study will be presented illustrating the process steps and equipment...

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日The grinding parts of a Loesche mill ( Fig. 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring system. Between the working surfaces of track and rollers, particle bed comminution takes place.

Processing of Magnetite Iron Ores–Comparing

2009年1月1日V arious magnetite ore grinding flow Eco-Efficient and Cost-Effective Process Design for Magnetite Iron Ore. Conference Paper As a result of dry magnetic separation at about 750 Gauss

sbm/sbm beneficiation process flow for iron ore grinding.md at

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Crushing Plant FlowsheetDesign-Layout Mineral

2016年3月10日The usual method of handling the ore is to arrange for each group of feeders to discharge on to one particular apron conveyor running parallel to the bin under the projecting ends of the feeders; the

process flow chart for iron ore dry grinding process

process flow chart for iron ore dry grinding process Flowchart Of Kaolin Beneficiation Process dry grind process flow sheet for feldspar mining flow chart of types of

Flow Chart Of Low Grade Iron Ore Processing Plant

Low Grade Iron Ore Grinding Flow Chart. China's iron ore grinding process, most use two stage grinding flowsheet, small and medium-sized concentrator is used more for a grinding process. Due to the fine

Process for recovering iron and rare earth in baotite low-intensity

2013年8月27日The invention belongs to the technical field of mineral engineering and aims at providing a process for recovering iron and rare earth in baotite low-intensity magnetic separation tailings. Iron content in the tailings in the existing technological process of a bayan obo iron mine is about 13% ordinarily, dissemination particles of

Iron ore crushing equipment and process flow mpl Ultrafine

2022年8月17日Iron ore crushing equipment and process flow. 2022-08-17 admin. from large pieces of raw iron ore (about 500mm) to millimeter-level fine materials. Usually, the iron ore dry separator is used to enrich the lean ore, and the enriched iron ore rich ore is sent to the ball mill for grinding, and then the iron concentrate is separated and

Iron Ore Processing Flow Sheet multotec

We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

Iron ore crushing and screening process sbmmill.net

2022年8月3日The iron ore processing and production process mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the three-stage closed-circuit crushing is more modern and suitable for high-hardness iron ore crushing and can complete the work of ore crushing and partial dissociation, thereby improving the

Dry Iron Ore Beneficiation ST EquipmentTechnology

Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits. STET has evaluated several iron ore tailings and run of mine ore samples at bench scale (pre-feasibility scale). Significant movement of iron and silicates was observed, with examples

Estimation of Grinding Time for Desired Particle Size SpringerLink

2020年1月3日Iron ores obtained from different sources differ in their chemical and physical properties. These variations make the process of grinding a difficult task. The work carried out in this context focuses on three different samples of iron ore, viz., high silica high alumina, low silica high alumina, and low silica low alumina. The grinding

High-Pressure Grinding Roller Presses for Minerals

The process takes place between two counter- rotating rollers, whereby the ore is choke-fed between the rollers. The feed material is compressed from the bulk density to 70–85 % of the real density and the individual particles are exposed to very high pressure.

Research of iron ore grinding in a vertical-roller-mill

2015年3月15日The grinding parts of a Loesche mill ( Fig. 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring system. Between the working surfaces of track and rollers, particle bed comminution takes place.

Processing of Magnetite Iron Ores–Comparing

2009年1月1日V arious magnetite ore grinding flow Eco-Efficient and Cost-Effective Process Design for Magnetite Iron Ore. Conference Paper As a result of dry magnetic separation at about 750 Gauss

Iron Ore Processing Flow Sheet multotec

We use cookies to improve your experience on our website. By using our site you agree to Cookies Policy

sbm/sbm beneficiation process flow for iron ore grinding.md at

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Flow Chart Of Low Grade Iron Ore Processing Plant

Low Grade Iron Ore Grinding Flow Chart. China's iron ore grinding process, most use two stage grinding flowsheet, small and medium-sized concentrator is used more for a grinding process. Due to the fine

process flow chart for iron ore dry grinding process

process flow chart for iron ore dry grinding process Flowchart Of Kaolin Beneficiation Process dry grind process flow sheet for feldspar mining flow chart of types of

Process Improvements for Direct Reduced Iron Melting in the

2021年2月23日Steelmaking based on direct reduced iron (DRI, and its compacted derivative hot briquetted iron, HBI) is an anticipated important global alternative to current steel production based on FeOx reduction in blast furnaces due to its lower specific CO2 emission. The majority of DRI is melted and refined in the electric arc furnace with

Process for recovering iron and rare earth in baotite low-intensity

2013年8月27日The invention belongs to the technical field of mineral engineering and aims at providing a process for recovering iron and rare earth in baotite low-intensity magnetic separation tailings. Iron content in the tailings in the existing technological process of a bayan obo iron mine is about 13% ordinarily, dissemination particles of

Figure 2. Flow chart of the grinding and blending

The process model contains three transfer functions between the speed of the moving grate and the pressures of the static and moving grates. The developed software achieves the identification of...

Iron ore crushing equipment and process flow mpl Ultrafine

2022年8月17日(1) Crushing process The iron ore crushing production line has the characteristics of high degree of automation, high crushing rate, low operating cost, energy saving and environmental protection, and fine particle size.

Iron ore crushing and screening process sbmmill.net

2022年8月3日Iron ore processing process Iron ore is gradually selected through the procedures of crushing, screening, grinding, classification, magnetic separation, flotation, gravity separation, roasting reduction, filtration and dehydration. A mineral aggregate containing iron element or iron compound is obtained.

Dry Iron Ore Beneficiation ST EquipmentTechnology

The iron ore production system usually involves three stages: mining, processing and pelletizing activities. Of these, processing ensures that an adequate iron grade and chemistry is achieved prior to the pelletizing stage.

Estimation of Grinding Time for Desired Particle Size SpringerLink

2020年1月3日Iron ores obtained from different sources differ in their chemical and physical properties. These variations make the process of grinding a difficult task. The work carried out in this context focuses on three different samples of iron ore, viz., high silica high alumina, low silica high alumina, and low silica low alumina. The grinding