Jaw Crusher Maintenance Details Procedures

Tips for Crusher Maintenance Thomasnet

2018年11月28日Maintenance Tips for Crushers Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants. Check jaw dies

Metso ® C Series™ jaw parts

On single toggle jaw crushers, the fixed jaw die may wear at a faster rate. The table on the right shows the indicative lifetime of the wear components. When to change jaw dies

进一步探索

Metso C series jaw crusher Manual SlideShareMetso® C’Series SparesReplacements CMS C根据热度为您推荐•反馈

The Most Practical Jaw Crusher Repair and Maintenance Manual

根据热度为您推荐•反馈

SERVICE TOOL GUIDE

Cone Crusher Tools Kodiak® Plus Cone Crushers Recommended Tools Part Number Description — Wedgeplate flipping fixture for K500+ 450132 Mantle wrench (2 lug)

Common Jaw Crusher Injuries, and How to Avoid Them Mellott

2017年3月20日Even premium jaw crushers will need maintenance at some point. Some of the most severe injuries occur while fixing equipment and replacing parts. There is an

Guidelines for Management Crushing and Screening

ejected from crushers and maintenance tasks all need careful management. 4.1 Crusher Blockage. A. Clearing blocked jaw crushers can be very hazardous and many plant

Crusher inspections Metso Outotec

Inspections give you the peace of mind that a problem won’t go unnoticed leading to equipment failure. By partnering with Metso Outotec, your equipment will be evaluated using established OEM procedures, proven

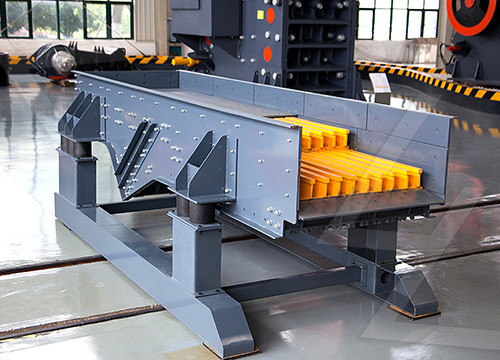

Maintenance of Material Handling Equipment Crushers

The main maintenance concern with screening equipment is regularly replacing screen media. Screen media replacement Depending on the types of panels you’re using for screening: wire cloth, urethane, or rubber, your

Construction Working and Maintenance of Crushers for

Construction Working and Maintenance of Crushers for Crushing Bulk

Maintenance Procedure Of Jaw Crusher

Operation and Maintenance of Jaw Crusher] 1. This procedure will set the machine to grind as fine as possible LubricationMaintenance Schedule Lubrication

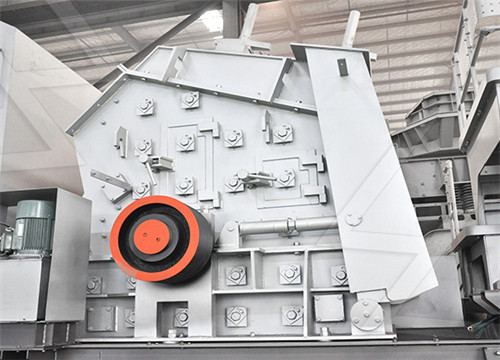

® C Series™ jaw crushers Proven reliability and

® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials.

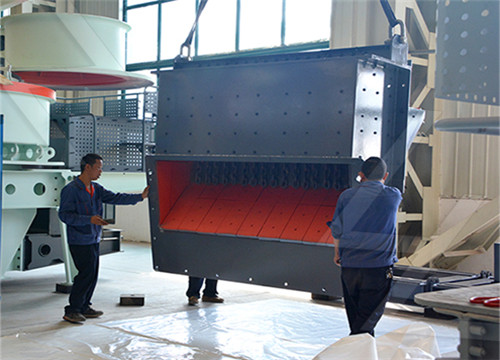

AMIT 129: Lesson 12 Crusher and Mill Operation Safety

Maintenance procedures must take account of manufacturer’s instructions and safety warnings. When performing maintenance inside large jaw crushers a specially designed platform may be inserted into the jaws to

SERVICE TOOL GUIDE

Cone Crusher Tools Kodiak® Plus Cone Crushers Recommended Tools Part Number Description — Wedgeplate flipping fixture for K500+ 450132 Mantle wrench (2 lug) 540014 Mantle wrench (3 lug) 456294 TIR Test Block 87091 Cavity Plug T16A-2 — Misc . set of caps/plugs 456531 Cone offset lifting eye 456532 Cone lifting eye 83074 Needle oil

Guidelines for Management Crushing and Screening final feb10

ejected from crushers and maintenance tasks all need careful management. 4.1 Crusher Blockage. A. Clearing blocked jaw crushers can be very hazardous and many plant operators have been killed carrying out this task. Blockage incidents can be greatly reduced by supplying rock that is properly sized to match the primary jaw opening.

Maintenance of Material Handling Equipment

The main maintenance concern with screening equipment is regularly replacing screen media. Screen media replacement Depending on the types of panels you’re using for screening: wire cloth, urethane, or rubber, your

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

EQUIPMENT AND MAINTENANCE

Keywords: Equipment, Maintenance, Crushers, Jaw crushers, Rock breakers, Refurbishing, Choking, Lubricating systems. field from the late 1800s to the early 1900s. In 1910 the largest gyratory cru shers built had 48-inch openings. However, about this time the jaw crusher came to life when the Power and Min

Mineral Processing Design and Operations ScienceDirect

The design of equipment use for the purpose is indicated in some details. Standard laboratory tests for determining this energy are described for ball and rod mills systems of grinding. Jaw Crusher. Book chapter Full text access. Chapter 4 Jaw Crusher. The correct procedures for estimating grades and concentrations are illustrated

Maintenance Procedure Of Jaw Crusher

If we make periodic maintenance schedule for jaw crusher, lubrication system, change lubrication oil etc. Its period is 1~3 months. 2. Medium repair of jaw crusher.

MBMMLLC: Jaw crusher maintenance and

112K subscribers We wanted to make a quick and easy instruction video for our jaw crusher. Included are instructions for jaw plate removal and replacement, greasing, jaw gap adjustment,...

® C Series™ jaw crushers Metso Outotec

Lifting tools for jaw dies, cheek plates and toggle plate as standard Optional flywheel and drive guards Optional maintenance platform Safe, quick and easy setting adjustment system Metso Outotec IC™ crusher automation Technical specifications Power, speed and weight Feed opening and capacity ® C Series™ crushers technical specifications

C Series Jaw Crushers hvmachinery

details, so as to ensure the highest possible functionality and reliability, without any compromises. Those who have owned and operated C Series jaw crushers know that not all jaw crushers are the same! Modular, non-welded construction A uniquely modular, non-welded frame construction is a state-of-the-art design with two hot-rolled steel side

Diesel Engine Jaw Crusher with Factory Price for Sale

1.Product Description PE200x300 details H engtong Model PE200x300 jaw crusher feeding size is 170mm, output size is 20 mm, capacity is 3-9 t/h. It's mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates,

MBMMLLC: Jaw crusher maintenance and operation video

2015年4月1日112K subscribers We wanted to make a quick and easy instruction video for our jaw crusher. Included are instructions for jaw plate removal and replacement, greasing, jaw gap

Guidelines for Management Crushing and Screening final feb10

ejected from crushers and maintenance tasks all need careful management. 4.1 Crusher Blockage. A. Clearing blocked jaw crushers can be very hazardous and many plant operators have been killed carrying out this task. Blockage incidents can be greatly reduced by supplying rock that is properly sized to match the primary jaw opening.

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk

C Series Jaw Crushers hvmachinery

details, so as to ensure the highest possible functionality and reliability, without any compromises. Those who have owned and operated C Series jaw crushers know that not all jaw crushers are the same! Modular, non-welded construction A uniquely modular, non-welded frame construction is a state-of-the-art design with two hot-rolled steel side

How does a Rock Crusher Work Jaw Crusher 911Metallurgist

2021年11月22日A jaw crusher frames are of sectionalized construction to facilitate handling. This design minimizes heavy lifts makes the crusher suitable for installations where parts must be passed down a shaft or through a tunnel. End members are attached between side members with vertical tongue and groove joints and held together with

EQUIPMENT AND MAINTENANCE

Keywords: Equipment, Maintenance, Crushers, Jaw crushers, Rock breakers, Refurbishing, Choking, Lubricating systems. field from the late 1800s to the early 1900s. In 1910 the largest gyratory cru shers built had 48-inch openings. However, about this time the jaw crusher came to life when the Power and Min

Evo Crusher Shearforce Equipment

The installer, operator and maintenance personnel must wear the suitable protection devices specified by Italian decree 81/2008, or the relevant safety legislation in force in the country where the equipment is used. ATTENTION Evo-Crusher declines all liability in the event of accidents if the installer, operator or maintenance personnel

Maintenance Procedure Of Jaw Crusher

If we make periodic maintenance schedule for jaw crusher, lubrication system, change lubrication oil etc. Its period is 1~3 months. 2. Medium repair of jaw crusher.

Jaw Crushers MEKA CrushingScreening Plants

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary

Diesel Engine Jaw Crusher with Factory Price for Sale

1.Product Description PE200x300 details H engtong Model PE200x300 jaw crusher feeding size is 170mm, output size is 20 mm, capacity is 3-9 t/h. It's mainly used at the primary stage of material reduction in several applications, including rock quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates,

® C Series™ jaw crushers Metso Corporation

Proven performance Convential jaw crusher design: C Series jaw crusher: Aggressive pitman motion Getting the kinematics of the movable jaw dies right is an important aspect when considering the performance of a jaw crusher. Our industry-leading stroke is amplified from top to bottom, being at its longest in the lower parts of the cavity.

Mineral Processing Design and Operations ScienceDirect

Detail descriptions of designs are given of large gyratory crushers that are used as primary crushers to reduce the size of large run-of-mine ore pieces to acceptable sizes. Descriptions of secondary and tertiary cone crushers that usually follow gyratory crushers are also given in detail.

smooth operation jaw rock crusher for sale, smooth operation jaw

Jaw Rock Crusher Equipment AC Motor Type Product Description Mobile Mining Equipment Rock Jaw Crushers Machine is used in the first working procedure of rock crushing in all kinds of mines. All kinds of ores whose compressive strength is not higher than 320MPa can be processed to medium granularity at one time. They often form a

- Buy Crusher And Leased To Others

- 山东滨州矿机

- Crushing Buckets Crushing

- hgm45286r高压磨粉机

- 采石场的废料是怎么处理的

- Gold Ore Beneficiation Flow Chart

- 河北中国露矿山开采工艺技术与装备现状和未来

- Crushing Equipments For Sale In South Africa For Iron Ore

- 铌钽精粉选矿技术流程是什么

- 广东矿渣立磨微粉生产线

- 钢球磨煤机 DTM290410

- 矿山设备的6种地面运输形式介绍

- San Plast Machine

- 69鄂式碎石机价格

- 圆锥破碎机标定是什么意思