Apron Feeder Impact

Everything You Need to Know about Apron Feeders McLanahan

2021年1月26日Apron Feeders can withstand extreme impact loading beyond the capability of other types of feeders. Apron Feeders provide the most accurate feed rate of all the feeders. Apron Feeders can meter

Long-lasting Apron Feeder increases productivity I

根据热度为您推荐•反馈

Apron Feeders MEKA Concrete Plants

An Apron Feeder is run at very low speeds and at a controlled feed rate as it absorbs the impact loads of the material falling from a dump truck or a front-end loader and is ideal for withdrawing material from under a

Apron feeders Metso Outotec

Apron feeders are a reliable solution for extracting or feeding ores that are wet, sticky, dry or even frozen. Apron feeder's diversity can be found throughout the mineral processing circuit fitting different applications with robust designs and high uptime for a more

Long-lasting Apron Feeder increases productivity I

The Apron Feeder for cement processing features heavy-duty roller supports throughout the full length of the feeder and a double set of rollers in the impact area, strengthening its ability to handle the enduring

Apron feeders Metso Outotec

Apron feeders are a reliable solution for extracting or feeding ores that are wet, sticky, dry or even frozen. Apron feeder's diversity can be found throughout the mineral processing circuit fitting different applications with robust designs and high uptime for a more efficient operation. Contact our sales experts

Apron Feeders AUMUND Group

Impact beams which have polymer liners and automatic lubrication over their entire length Apron Feeder type BPB and KZB-S for medium-duty applications Cost-effective solution for discharging of hoppers and

AF Apron Feeder

The feeder is built into a sturdy frame with rails. The rails carry the chains that have grease-lubricated rollers. The aprons are designed to deflect a little when hit by big rocks. The impact is absorbed by the aprons themselves and by impact rollers placed below the aprons. The impact rollers, which are lubricated by a central greasing unit,

Apron feeders: the material handling workhorses

2019年10月3日Normally, the optimal speed of an apron feeder is 0.05-0.40 m/s. If the ores are non-abrasive, the speed can increase to above 0.30 m/s due to the likely reduced wear. Higher speeds would hurt an

Apron feeder upgrades Metso

apron feeder solutions. Benefits • Maximize equipment performance with a cost-effective solution • Gain new functionality with Apron feeder pans often experience severe impact and wear during day-to-day operation, becoming thin or even flexing and breaking. This can cause spillage of fines, lengthy downtime, and

Industrial Solutions Apron feeders ThyssenKrupp

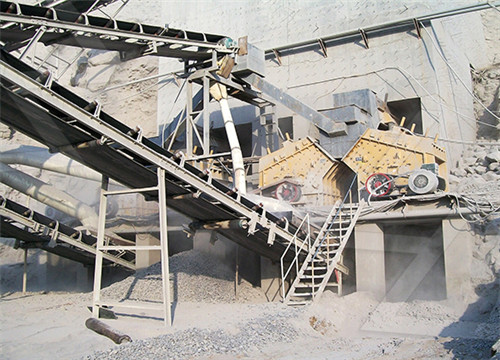

Apron feeder RKF 2.2 x 15.8 D8 with inboard chain Apron feeder RKF 3.4 x 17.0 D9 with outboard chain Apron feeders are designed for conveying capacities of more than 14,000 t/h and can be integrated into stationary, semi-mobile or mobile plants. Stationary single-shaft impact crusher (right) fed by two apron feeders

Apron feeder parts Metso Outotec

Why upgrade your apron feeder? Safety and reliability Superior safety with fewer repairs and maintenance, lower noise, less spillage and a cleaner environment. Lower environmental impact Retrofits and refurbishments

MMD Group of Companies Feeders

The MMD Heavy Duty Apron Plate Feeder is designed to handle high impact loads created from large ROM material directly dumped. Used in many types of mineral and ore applications around the world, plate

Anderson Columbia Benefits from Reliability and McLanahan

The Apron Feeder accepts bucketloads of quarry shot material and conveys it to a Wobbler Feeder. The Wobbler Feeder is able to scalp out some of the clay before it enters the MaxCap Impact Crusher. The MaxCap and Wobbler Feeder were installed on a five-axle chassis and the Apron Feeder was installed on a separate quad-axle chassis for ease of

Apron Feeders Mineral ProcessingMetallurgy

2016年5月31日An apron feeder is in fact a conveyor that is constructed from metal. It regulates the feed by carrying the ore to the delivery point at a controlled rate of speed. The face of the conveyor is made from heavy

Apron Feeders TAKRAF TAKRAF GmbH

Robust and reliable for extended service life Our feeders combine heavy-duty frames with standard chains and rugged pans (cast manganese steel or formed carbon steel) to provide an extended service life. Impact rails below the pans also minimize deflection and absorb the forces of falling material.

Apron Feeders AGGRETEK heavy duty apron feeders

The Apron Feeder has a remote mounted electrically operated automatic greasing system as standard. TAIL TRACTION WHEELS Cast steel traction wheels are lighter duty as they act purely as a directional guide to centralise the track.

Products Keestrack

Reversible Impact I Series Reversible Impact I Series I4e. Impact R Series Impact R Series R3. R5. R5e. R6. Cone H Series Cone H Series H4e. H6e. H6Se ZERO. H7e ZERO. Tracked Apron Feeders. A Series A Series A6e. Milling Machines. F Series F Series F6. PartsServices ; NewsPress ; About us

Apron Feeder SAF

2023年2月10日Our Apron Feeder SAF’s pans are welded from high wear resistant steel. The hopper zone has additional rollers and slide rails to ensure uniform load distribution on the main frame of the apron feeder. For additional protection of the supporting structure, the Apron Feeder can be equipped with an impact table with heavy-duty shock absorbers.

Apron feeder rollers Extend the life of your Apron feeder

impact rollers With ’s specially designed impact rollers, you can improve the performance and extend the life of your Apron feeder. Rollers can be retrofitted to all types of Apron feeders and to most third-party feeders. We are providing the new design of support rails together with the new rollers.

HAF Apron Feeder Hazemag North America

The HAF apron feeder offers an excellent solution for a highly controlled, uniform extraction of the given raw material from the primary feed hopper. Cement and aggregate producers around the world have

AF Apron Feeder

The feeder is built into a sturdy frame with rails. The rails carry the chains that have grease-lubricated rollers. The aprons are designed to deflect a little when hit by big rocks. The impact is absorbed by the aprons themselves and by impact rollers placed below the aprons. The impact rollers, which are lubricated by a central greasing unit,

Apron feeders: the material handling workhorses

2019年10月3日Normally, the optimal speed of an apron feeder is 0.05-0.40 m/s. If the ores are non-abrasive, the speed can increase to above 0.30 m/s due to the likely reduced wear. Higher speeds would hurt an

Apron feeder upgrades Metso

apron feeder solutions. Benefits • Maximize equipment performance with a cost-effective solution • Gain new functionality with Apron feeder pans often experience severe impact and wear during day-to-day operation, becoming thin or even flexing and breaking. This can cause spillage of fines, lengthy downtime, and

Apron Feeder HAF

’s HAF Apron Feeders are used for feed hopper discharging in primary crushing plants, and as a loading or discharging conveyor in, for example, the cement and raw material industry. Apron Feeders provide capacities of up to 4,000 t/h with piece sizes up to 3m 3. When selecting a suitable hopper discharge unit, it is very

Industrial Solutions Apron feeders ThyssenKrupp

Apron feeder RKF 2.2 x 15.8 D8 with inboard chain Apron feeder RKF 3.4 x 17.0 D9 with outboard chain Apron feeders are designed for conveying capacities of more than 14,000 t/h and can be integrated into stationary, semi-mobile or mobile plants. Stationary single-shaft impact crusher (right) fed by two apron feeders

MMD Group of Companies Feeders

The MMD Heavy Duty Apron Plate Feeder is designed to handle high impact loads created from large ROM material directly dumped. Used in many types of mineral and ore applications around the world, plate

Anderson Columbia Benefits from Reliability and McLanahan

The Apron Feeder accepts bucketloads of quarry shot material and conveys it to a Wobbler Feeder. The Wobbler Feeder is able to scalp out some of the clay before it enters the MaxCap Impact Crusher. The MaxCap and Wobbler Feeder were installed on a five-axle chassis and the Apron Feeder was installed on a separate quad-axle chassis for ease of

Home

PRIMARY IMPACT CRUSHER HPI. With throughput rates up to 2,500 t/h, HPI Primary Impactors are used extensively in the cement, aggregate and recycling industries. Apron Feeder HAF. Used in

Products Keestrack

Reversible Impact I Series Reversible Impact I Series I4e. Impact R Series Impact R Series R3. R5. R5e. R6. Cone H Series Cone H Series H4e. H6e. H6Se ZERO. H7e ZERO. Tracked Apron Feeders. A Series A Series A6e. Milling Machines. F Series F Series F6. PartsServices ; NewsPress ; About us

CONCEPTS OF FEEDER DESIGN AND PERFORMANCE IN

Figure 1: Belt or Apron Feeder . In the case of vibratory feeders, there is a tendency for feed to occur preferentially from the front. To overcome this problem, it is recommended that the slope angle of the front face of the hopper be increased by 50 to 80 as illustrated in Figure 2. Alternatively, the lining surface of the front face in the

Apron feeder Share and Discover Knowledge on SlideShare

2018年3月26日An Apron Feeder is run at very low speeds and at a controlled feed rate as it absorbs the impact loads of the material falling from a dump truck or a front-end loader and is ideal for withdrawing material from under a stockpile or from under a Primary Crusher.