Processing Superfine Powder Hottest Vibrating Screen For Plate Corundum

CNU Corundum micro-powder vibration

The utility model provides a corundum miropowder vibration classifying screen for solve current vibration classifying screen and adopt the fix with screw in the device,

Vibrating Screens for powder and bulk solids

根据热度为您推荐•反馈

WEILIANG ultrasonic vibrating screen for ultra-fine powder

2019年6月1日Hi, it's Maria from Xinxiang Weiliang Sieving Machinery Co., Ltd. We are the manufacturer of screening machines in China, and we are specialized in FINE siev...

Ultrasonic vibrating screen for difficult screening fine powder

2021年12月18日ultrasonic vibrating screen features: 1. It is suitable for separating powder through 20 micron to 300 micron screen, especially for materials difficult to

Application of ultrasonic vibrating screen in white corundum

2021年12月17日In addition, in order to meet the needs of multi particle size classification of white corundum, Zhentai stainless steel ultrasonic vibrating screen can customize 3

A vibrating screen for self sharpening corundum abrasive [utility

2021年12月20日Abstract: the utility model discloses a vibrating screen for self sharpening corundum abrasive, which comprises an electromagnetic vibrator, one side

2013 Processing Superfine Powder Hottest Ultrasonic Vibrating

Buy 2013 Processing Superfine Powder Hottest Ultrasonic Vibrating Screen from Machine Business Opportunities, 2013 Processing Superfine Powder Hottest

vibrating screen panel Welcome to TablesThyme

SCREEN PANELS YUDIN Equipment. We manufacture and supply vibrating screen panels for different types of vibrating screens. Our product range covers a wide range

Ultrasonic vibrating sieve XinXiang YiHu Machinery

This device can make the screen surface superpose ultrahigh frequency vibrational energy, so that it can keep clear of the mesh and achieve the ideal screen situation. Ultrasonic

Design of Vibrating Screen Separation Equipment for

2022年5月1日The vibrating screen has absolute advantages in the sorting equipment due to its simple structure, reliable operation and large processing capacity. Therefore, the vibrating scree

CNU Vibrating screen device for processing chromium corundum

The utility model provides a chromium corundum processing is with sieving mechanism that shakes, including first fixed plate, first fixed plate upper portion is provided with damper, damper upper portion is provided with the sieve, damper includes first spacing seat, be provided with first shock pad in the first spacing seat, first shock pad upper portion is

CNU A improved generation linear vibration sieve for

The utility model discloses an improved generation linear vibrating screen for white alundum production and processing, including the main tank body, hourglass material layer and screen, the spacing of edge fixedly connected with of main tank body upper surface, the inside sliding connection of spacing has the slide bar, the one end fixedly connected with

High-frequency vibrating screens Wikipedia

High-frequency vibrating screens usually operate at an inclined angle, traditionally varying between 0° and 25° and can go up to a maximum of 45°. They should operate with a low stroke and have a frequency ranging from 1500 to 9000 RPM. Frequency in High frequency screen can be fixed or variable.

Material classification for fine powders Processing Magazine

2021年10月18日This ultrasonic vibration breaks the surface tension between the material and the screen, allowing particles to pass through more easily. This method cannot be used in applications where the material is too fine or too coarse, however, and is one of the more expensive classifying options. Air classification equipment

Screening/Sizing McLanahan

Screens can also be used in other stages of the processing plant to produce a final, saleable product, as well as to dewater washed material to less than 14 percent moisture for easy conveying and/or stockpiling. To size and separate material, screening equipment employs a vibrating or tumbling action that causes the feed material to divide by

Application of ultrasonic vibrating screen in white corundum powder

2021年12月17日In addition, in order to meet the needs of multi particle size classification of white corundum, Zhentai stainless steel ultrasonic vibrating screen can customize 3-4 layers according to the needs to realize 4-5 kinds of particle size classification at one time. ultrasonic vibrating screen has seven advantages in screening white corundum powder

The advantages and disadvantages of vibrating screen sieve

2022年1月4日Punching screens are generally formed by punching round, square or rectangular screen holes on a steel plate with a thickness of 5-12mm. Compared with the round or square sieve plate, the rectangular sieve has a larger effective area, lighter weight, and higher productivity.

Corundum from basaltic terrains: a mineral inclusion

Corundum samples were first examined under a binocular mi-croscope and those with inclusions were mounted in epoxy, fol-lowed by careful cutting using a fine diamond wheel. When the inclusions appeared close to the cut surface, the samples were repeatedly ground on 15-micron corundum powder until the min-eral inclusions were exposed at the surface.

Processing technology of natural quartz sand ALPA-micro silica powder

2020年12月18日According to the actual requirements, the fine powder of 120 mesh is separated, and the sand after air separation is screened by multi-layer vibrating screen, 20 ~ 40 mesh, 40 ~ 60 mesh, 60 ~ 80 mesh, 80 ~ 120 mesh, etc. the dust points in the whole process are effectively controlled, no dust spillover, and the environment is friendly.

Supply Centrifugal Superfine Mill 0371- Xinxiang

2021年12月19日Xinxiang Qianyi Vibrating Screen Manufacturer. E-mail:[email protected]. Tel:+86-. Nemesis of high hardness and difficult to process materials: when grinding processing materials such as silicon carbide, corundum, zircon sand and iron powder, with . Document Format:. " Doc document

Fine vibrating screen, Fine vibrating screen direct from Xinxiang

Fine vibrating screen from Xinxiang First Vibration Machinery Factory Co., Ltd.. Dia 2000 mm Food processing industry Tumbler sieve machine hot sales in 2023 / unit. 1 unit Automated corn starch vibratory separator vibrating sifter vibration machine screen vibrating machine for fine powder. Fine Powder Making. Motor. Circular. $880.00

Small Vibration Machine For Corundum/round vibration sieve

The price of jade and corundum small Vibration Machine For Corundum/round vibration sieve factory/screener vibrating/shaker screen/sieve shaker price produced and sold by Xinxiang Dayong Vibrating Equipment Co., Ltd. is dedicated to screening jade and corundum.The rotating vibrating screen has high screening efficiency, and the screen

CNU Vibrating screen device for processing chromium corundum

The utility model provides a chromium corundum processing is with sieving mechanism that shakes, including first fixed plate, first fixed plate upper portion is provided with damper, damper upper portion is provided with the sieve, damper includes first spacing seat, be provided with first shock pad in the first spacing seat, first shock pad upper portion is

CNU A improved generation linear vibration sieve for

The utility model discloses an improved generation linear vibrating screen for white alundum production and processing, including the main tank body, hourglass material layer and screen, the spacing of edge fixedly connected with of main tank body upper surface, the inside sliding connection of spacing has the slide bar, the one end fixedly connected with

Design of Vibrating Screen Separation Equipment for

2022年5月1日The vibrating screen has absolute advantages in the sorting equipment due to its simple structure, reliable operation and large processing capacity. Therefore, the vibrating scree

Material classification for fine powders Processing Magazine

2021年10月18日Fine powder separation equipment. Fine powder separation equipment operates by one of two mechanisms: mechanical separation or air classification. Mechanical separation uses screens that allow small particles to pass through while holding back and redirecting oversized particles.

Screening/Sizing McLanahan

To size and separate material, screening equipment employs a vibrating or tumbling action that causes the feed material to divide by size. The screen media removable, easily replaceable panels attached to the deck frame through which undersized particles pass makes the separation by allowing smaller particles to pass through its openings.

A vibrating screen for self sharpening corundum abrasive [utility

2021年12月20日Abstract: the utility model discloses a vibrating screen for self sharpening corundum abrasive, which comprises an electromagnetic vibrator, one side outer wall of the electromagnetic vibrator is fixedly connected with a control panel, the top outer wall of the electromagnetic vibrator is fixedly connected with a vibrating spring,

Sand Production Processing Plant Fine Sieving Linear Vibrating Screen

Sand Production Processing Plant Fine Sieving Linear Vibrating Screen Powder Sieving Machine,Find Complete Details about Sand Production Processing Plant Fine Sieving Linear Vibrating Screen Powder Sieving Machine,Fine Sieving Linear Vibrating Screen,Linear Vibrating Screen Sieving Machine,Vibrating Powder Sieving Machine

The advantages and disadvantages of vibrating screen sieve

2022年1月4日Punching screens are generally formed by punching round, square or rectangular screen holes on a steel plate with a thickness of 5-12mm. Compared with the round or square sieve plate, the rectangular sieve has a larger effective area, lighter weight, and higher productivity.

Petroleum coke superfine grinding Xinxiang Qianyi Vibrating Screen

2021年12月17日Xinxiang Qianyi Vibrating Screen Manufacturer. E-mail:[email protected]. Tel:+86-. It is mainly applicable to the superfine powder processing of non flammable and explosive brittle materials with medium and low hardness and Mohs hardness, such as calcite chalk limestone dolomite

For Zhaoqing brown corundum vibrating screen, one side of the

2021年12月19日The lower part of the vibrating screen is provided with a bearing which is respectively fixed in the channel steel on the frame for linear reciprocating motion; The upper coarse screen of the screen is to clean the large particle impurities in the material, while the lower fine screen is to clean the small particle impurities in the material.

Corundum from basaltic terrains: a mineral inclusion

When the inclusions appeared close to the cut surface, the samples were repeatedly ground on 15-micron corundum powder until the min- eral inclusions were exposed at the surface. This lengthy process ensures the largest inclusion exposure and minimal loss of the relatively soft inclusions.

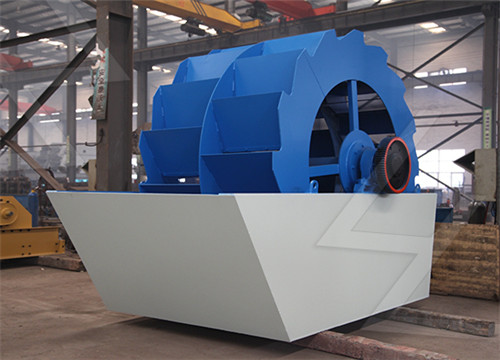

S49-800 Vibrating sieve screen for brown corundum

Vibrating screen for industrial,show the detail of S49-800 Vibrating sieve screen for brown corundum on China Suppliers . Product Details. Our vibrating screens can handle wide range of materials in building dustry,such as dry or wetcoarse or fine. Check which material you want to be screened. building industry

rotary ultrasonic vibrating sieve for fine powder

Compared with the ordinary three dimensional vibrating screen, the accuracy can be increased by 1% -70%, the processing capacity can be increased 1-10 time. • Perfect sieving of size 10mesh ~ 635mesh. • No screen blinding and clogging. • Bonding type screen design, no corner collect materials. • Suitable for super-fine screening.

Ultrasonic powder sieving machine ZHENYING

Ultrasonic vibrating screen is usually used in screening superfine powder which the ordinary vibrating screen can not solved. Application. Realize the high precision sieving to achieve the best sieving effect. Screening precision can raise to 1~100%, the output can be raised to 0.5~10 times.