Concrete Crusher To Recycle Concrete

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER

Mobile Concrete Crushers: 90-385 TPH RUBBLE MASTER Dominate the Jobsite With a RUBBLE MASTER Concrete Crusher Mobile crushers for processing concrete building slabs, bridgedeck, sidewalk, curbing, pipe, and high PSI runway concrete. watch video

进一步探索

Small Jaw Crusher For Sale Low Cost Of Mini Jaw CrusherCrusher, Concrete For Sale 372 Listings MachineryTradMobile Crusher Rental: Concrete, Asphalt, Rock RUBBLE 5 Types of Concrete Crushers for Recycling Concrete BloUsed Portable Jaw Crushers for sale. Metso equipment根据热度为您推荐•反馈

5 Types of Concrete Crushers for Recycling Concrete Blocks

2023年2月28日To recycle concrete, a crushing process is required. There are mainly 5 types of concrete crushers like portable crusher, mobile crusher, small concrete

Mobile Impact Crushers RUBBLE MASTER

Mobile impact crushers are used to recycle concrete and asphalt and process natural rock. They are easy to move on and between job-sites, which allows operators to crush

进一步探索

Portable Rock Crusher / Aggregate Crushing Plant For Sale Mobile Crusher Eastman Rock Crusher根据热度为您推荐•反馈

Concrete recycling Wikipedia

OverviewImportanceProcessUsesChemical Recycling of Concrete Waste[20]PrecautionsExternal links

Concrete recycling is the use of rubble from demolished concrete structures. Recycling is cheaper and more ecological than trucking rubble to a landfill. Crushed rubble can be used for road gravel, revetments, retaining walls, landscaping gravel, or raw material for new concrete. Large pieces can be used as bricks or slabs, or incorporated with new concrete into structures, a materi

Small Concrete Komplet Crushers For Sale Komplet

2018年10月20日The K-JC503 mobile jaw crusher creates the best opportunities to save money on excavation and demolition waste

Concrete CrushingRecycling Demolition Asset

Concrete crushing is a process in which we grind concrete into gravel that you can reuse and recycle. Before our Oregon demolition experts can crush concrete, they tear down the respective building using precision

Can Concrete Be Recycled? Recycling Concrete Concrete

According to the American Concrete Pavement Association, recycling of concrete pavement is a relatively simple process. It involves breaking, removing and crushing concrete from an existing pavement into a

The 411 on Recycled Concrete: Uses, Benefits, and How To

Recycled concrete can also be used to create 2”-4” recycled stone. This product is typically used for site stabilization, bottom layer road base, and backfill. Besides stone, recycled concrete can also be used to create

Recycled Aggregates Cement

Recycling of concrete is a relatively simple process. It involves breaking, removing, and crushing existing concrete into a material with a specified size and quality. See ACI 555 (2001) for more information on processing

Concrete Crusher Industrial Demolition Equipment

The concrete crusher at Elder Demolition makes us one of the most environmentally proactive demolition companies in Oregon and the Northwest. The impressive equipment

Mobile Impact Crushers RUBBLE MASTER

Mobile impact crushers are used to recycle concrete and asphalt and process natural rock. They are easy to move on and between job-sites, which allows operators to crush on smaller job-sites. Best of all they often come with an on-board screen attachment to produce spec products eliminating the need for additional screening equipment on-site.

Small Portable Concrete Crushers, Screeners,Shredders

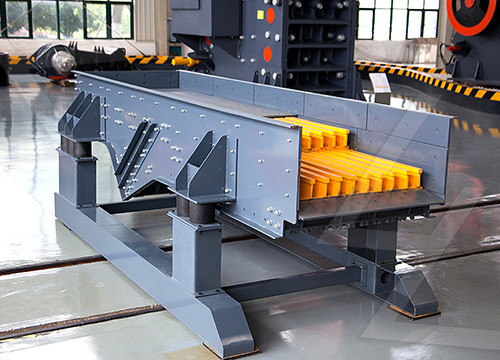

Compact concrete crushers offer performance, mobility, maneuverability, and above all safety. Don’t waste downtime between excavation removal and material replacement. See immediate savings in time, labor and expense when you crush and recycle on-site with Komplet mini crushers. K-JC503 K-JC704 K-JC805 Vibrating Screeners

Concrete Block Crusher for Recycling Rejects RUBBLE MASTER

RM60 Crusher Industrial Production Waste Cinder block rejects at a manufacturing plant are crushed and screened to 2 finished products. Product 1: 3/8"- (8mm-) Product 2: 3/8" 1" (8-25 mm) clear stone. Mobile Impact Crushers RUBBLE MASTER offers a large range of mobile Impact Crushers ranging from 90 to 385 TPH. RM 100GO! RM 90GO!

Recycled Aggregates Cement

Recycling of concrete is a relatively simple process. It involves breaking, removing, and crushing existing concrete into a material with a specified size and quality. See ACI 555 (2001) for more information on processing

Ways to Recycle and Reuse Concrete liveabout

2019年1月7日Concrete is recycled by using industrial crushing equipment with jaws and large impactors. After the concrete is broken up, it is usually run through a secondary impactor and is then screened to remove dirt and particles and to separate the large and small aggregate. Additional processes and equipment, such as water flotation,

Portable Crushing Cherry Companies

Our portable crushing equipment can recycle concrete and asphalt at your work site. Recycling concrete and asphalt at your site makes it easier and cheaper for your organization to recycle. Benefits of onsite concrete and asphalt crushing include: Quality base material for re-use onsite Lower landfill space Reduced tipping fees

Recycled Concrete Aggregate- How to Make It and What Is It

2023年2月15日Waste concrete from building and demolition even being crushed by crushers, still contains a small amount of combustibles such as chips and plastic chips. To produce purer and more valuable recycled concrete aggregate, calcination and grinding process is added after crushing, sieving, and contamination removing.

7 types Concrete Crusher for Recycling Concrete

2022年12月19日Concrete crushing plants, also known as concrete recycling plants, are an environmentally friendly and cost-effective way to recycle concrete and other construction materials. The crushed concrete is then re-used as aggregate in new construction projects, making it an economical and sustainable solution for construction

Types of Concrete Crushers Hill Demolition

Concrete crushers are among the most common bits of machinery used in demolition. Each individual project may require a specific type of concrete crusher, but it all depends on the goals and the type of concrete involved. This month, at Hill Demolition, we’re going to guide you through the three most common concrete crusher types.

sbmchina/sbm construction of concrete crushing recycling in

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Concrete Crusher for sale for concrete recycling Mobile

Summary: Concrete crusher for recycling concrete slabs, bridge deck, sidewalk, curbing, pipe, and high PSI runway concrete. Concrete crushed stone is made by mechanical crushing (with a concrete crusher) of natural rock, pebbles, or mine waste rock, such as bluestone, basalt, pebbles, granite, etc.

The cleaner the better ConstructionDemolition Recycling

Concrete crushing plants produced by original equipment manufacturers (OEMs) virtually always include OEM-installed magnets because manufacturers likely expect reinforced concrete to be among the materials being crushed. In a 2021 interview with ConstructionDemolition Recycling, a scrap buyer from one of the largest scrap metal companies

WhyHow to Use Recycled Crushed Concrete

2019年11月7日Recycling crushed concrete to be reused helps reduce landfill crowding AND saves more resources from being used to create new concrete. Old concrete can be crushed down to specific sizes, cleaned

Concrete Recycling Southern California Ramco

Concrete recycling starts by taking debris and crushing it into smaller pieces. This crushed concrete is known as recycled concrete aggregate (RCA). After the initial pass through the first crusher, RCA gets sent down a conveyor belt and sifted through to check for ferrous metals, dust, and dirt.

Concrete Block Crusher for Recycling Rejects RUBBLE MASTER

How to recycle cinder blocksbricks? Cinder blocks, brick pavers and red brick can be crushed with ease at a high production rate. RUBBLE MASTER offers a wide range of compact crushers and screens to process your material into a high-quality commodity product for sale or reuse in the manufacturing process. High Quality Product

The Concrete Recycling Process TRP Ready Mix

2018年12月10日To recycle concrete, the concrete must first be broken and removed from the existing pavement—i.e., the demolition of concrete foundations, driveways, sidewalks, and other concrete structures.

Ways to Recycle and Reuse Concrete liveabout

2019年1月7日Fortunately, concrete can be recycled and reused in many ways. Typically (but not always) the process involves crushing or pulverizing the concrete rubble near the demolition or building site. Choosing the best method often depends on the size and shape of the concrete pieces to be recycled.

K-JC503 Mobile Mini Jaw Crusher Komplet America

The K-JC503 mobile jaw crusher creates the best opportunities to save money on excavation and demolition waste removal by creating byproducts that can be repurposed. Our lightweight compact jaw crushers open

Recycled Concrete Aggregate- How to Make It and What Is It

2023年2月15日Waste concrete from building and demolition even being crushed by crushers, still contains a small amount of combustibles such as chips and plastic chips. To produce purer and more valuable recycled concrete aggregate, calcination and grinding process is added after crushing, sieving, and contamination removing.

7 types Concrete Crusher for Recycling Concrete

2022年12月19日Concrete crushing plants, also known as concrete recycling plants, are an environmentally friendly and cost-effective way to recycle concrete and other construction materials. The crushed concrete is then re-used as aggregate in new construction projects, making it an economical and sustainable solution for construction

Types of Concrete Crushers Hill Demolition

Concrete crushers are among the most common bits of machinery used in demolition. Each individual project may require a specific type of concrete crusher, but it all depends on the goals and the type of concrete involved. This month, at Hill Demolition, we’re going to guide you through the three most common concrete crusher types.

The cleaner the better ConstructionDemolition Recycling

Concrete crushing plants produced by original equipment manufacturers (OEMs) virtually always include OEM-installed magnets because manufacturers likely expect reinforced concrete to be among the materials being crushed. In a 2021 interview with ConstructionDemolition Recycling, a scrap buyer from one of the largest scrap metal companies

Materials Free Full-Text Influence of Mechanical Screened

2023年2月10日The use of recycled coarse aggregates (RA) in concrete is a sustainable alternative to non-renewable natural aggregate (NA) to fabricate concrete products using in concrete structures. However, the adhered mortar on the surface of RA would considerably impact the qualities of concrete products. As a practical treatment procedure,

sbmchina/sbm construction of concrete crushing recycling in

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

Concrete Recycling Is Already a Reality ArchDaily

2022年1月10日Through this simple crushing process, the fragments end up used as base materials for structures such as roads, or other similar uses. "Concrete Recycling Is Already a Reality" [A reciclagem

How Does a Concrete Crusher Work Training on Crushing

Komplet America is the distributor of premium portable waste recycling machines and quality material processing equipment. We are excited to bring 20 years of Komplet small mobile crushers, screeners, and shredders to the USA. Finally an affordable, reliable solution for crushing, screening, and shredding!

Recycled Aggregates Cement

Recycling of concrete is a relatively simple process. It involves breaking, removing, and crushing existing concrete into a material with a specified size and quality. See ACI 555 (2001) for more information on processing old concrete into recycled concrete aggregates.

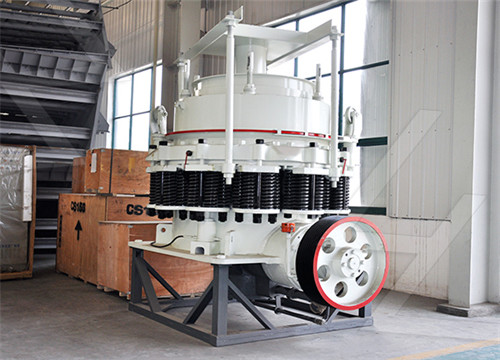

Concrete Recycling Plants

Jaw Crushers Jaws compress the concrete between a stationary and moveable plate. Concrete is reduced in size as it travels down the length of the wedge between the two plates. Jaws are used as primary crushers and typically produce a 4" to 8" minus product usually used as fill.