Dynamic Separator For Sand Grinding

Overview of Christian Pfeiffer separators Christian Pfeiffer

Separators QDK-S QDK-L QDK-K QDK-M QDK-T Fix and QDK-F ROC Object Classifier U-ROC HEYD Complementary Products Allmax® Grinding balls Services

High Efficiency Dynamic separator Detail overview about

根据热度为您推荐•反馈

Dynamic Separator Manufacturer -Greenfield Tech

2023年3月1日A Dynamic Separator is an industrial machine which sorts materials by a combination of size, shape, and density. It works by injecting the material stream to be sorted into a chamber which contains a column

USA Dynamic separator for a grinding mill

A dynamic separator for a grinding mill having a stator installed in a stationary manner and a rotor provided on a rotary shaft such that it faces the stator. Between the stator

GRINDING AND SEPARATING TECHNOLOGY SYSTEMS

Grinding of coal and other explosive materials requires observing of safety rules of operation: Materials can explode under the following conditions: 1. Concentration of

US Patent for Dynamic separator for a grinding mill

A dynamic separator for a grinding mill having a stator installed in a stationary manner and a rotor provided on a rotary shaft such that it faces the stator. Between the stator

Dynamic separator efficiency, SEPOL, O-Sepa, Sepax etc

online cement plant live calculator for dynamic separator calculation, Efficiency on Coarse basis, fine basis, efficiency against residues of mill output separator input and return

Turnkey Project Solutions and Turnkey Plant Solutions

Expertise in providing grinding solutions for almost every mineral whether gold, chrome, limestone or even river sand. KNOW MORE. Dynamic. Separators. Dynamic Separators. For best efficiency of your grinding

Dynamic Separator For Sand Grinding goriaindustries

Separator Optimization In Cement Mill. Aug 18, 2018 Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system

Separators KHD Humboldt Wedag

Grinding An integral part of grinding circuits, your separator can have a major impact on the performance of the entire grinding process and the quality of your end product. The basic job of a separator is to separate on-spec material from oversize.

SKS-VZ KHD Humboldt Wedag

It is important to underline: the SKS-V/Z separator can fit in restricted spaces. It has the lowest height and diameter of all our dynamic separators with the smallest distance between inlet and outlet flange. Indeed, because of its size, it can be positioned on the same platform as a roller press.

Modeling of the separation process in dynamic separators

2013年1月1日Download Citation Modeling of the separation process in dynamic separators The advantages of use closed circuit grinding cement clinker and additives into a ball mill shown. A mathematical

Particle size reduction, screening and size analysis Objective

Wet grinding should be considered in cases where the material is prone to static charging, or when the material is toxic and dust containment is difficult. Also wet grinding can be used when the final product size is extremely fine since production of nanoparticles is possible with wet grinding. Pigments for inks and

US Patent for Dynamic separator for a grinding mill Patent

A dynamic separator for a grinding mill having a stator installed in a stationary manner and a rotor provided on a rotary shaft such that it faces the stator. Between the stator and the rotor is provided a small gap for the passage of processed material in order to separate and discharge the processed material from the dispersion media. The rotor is arranged

Dynamic separator efficiency, SEPOL, O-Sepa, Sepax etc

online cement plant live calculator for dynamic separator calculation, Efficiency on Coarse basis, fine basis, efficiency against residues of mill output separator input and return coarse material

Turnkey Project Solutions and Turnkey Plant Solutions Chanderpur

Expertise in providing grinding solutions for almost every mineral whether gold, chrome, limestone or even river sand. KNOW MORE. Dynamic. Separators. Dynamic Separators. For best efficiency of your grinding system and better quality of your product.

Dynamic Separator For Sand Grinding goriaindustries

Separator Optimization In Cement Mill. Aug 18, 2018 Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants.The function of the separator is to separate the fine-sized particles from the coarse-sized particles, so as to avoid material condensation and over

RTKM separator for coal grinding ball mills

The RTKM separator is specially designed for use with ball mills that grind coal, petcoke or charcoal. It is an energy-efficient and well-proven solution which incorporates the experience attained from over 1500 high efficiency dynamic air separators supplied by in grinding applications. The RTKM separator is the obvious choice for new

Dynamic Separator Karthi PDF Mill (Grinding) Force Scribd

separator will treat them as a big particle. The return of the agglomerates for further grinding will hamper the process and reduce the overall efficiency. The separator is constructed in such a way that it will ensure a high degree of dispersion of the individual particles in all the agglomerates.

LNME 1 CFD Modeling of the High Efficiency Rotor

particle is sent for supplementary grinding. The trick is to ascertain that the coarse fraction doesn’t contain fine particles on one hand and, to ensure that the fine frac-tion doesn’t contain coarse particles on the other hand. Separators can be divided into two groups: static separators or cyclones and dynamic separators or high effi-

Vertical Roller Mills

When it comes to grinding raw coal, savings in specific energy consumption can be achieved with vertical roller mills. Specific energy consumption depends on the grindability of the raw coal and the coal meal fineness required. A dynamic separator that ensures high separation efficiency also helps to reduce specific energy use.

CFD Modeling of the High Efficiency Rotor Separator in Cement Grinding

The results proved that the RSM model better captures the phenomenon in the dynamic separator when compared with experimental results made by the Enfidha Cement plant CE. M., Hatem, M., Bournot, P. (2013). CFD Modeling of the High Efficiency Rotor Separator in Cement Grinding Circuit. In: Haddar, M., Romdhane, L., Louati, J., Ben

sbm/sbm grinding system with static and dynamic separators

Contribute to changjiangsx/sbm development by creating an account on GitHub.

Vertical Roller Mills

When it comes to grinding raw coal, savings in specific energy consumption can be achieved with vertical roller mills. Specific energy consumption depends on the grindability of the raw coal and the coal meal fineness required. A dynamic separator that ensures high separation efficiency also helps to reduce specific energy use.

LNME 1 CFD Modeling of the High Efficiency Rotor

particle is sent for supplementary grinding. The trick is to ascertain that the coarse fraction doesn’t contain fine particles on one hand and, to ensure that the fine frac-tion doesn’t contain coarse particles on the other hand. Separators can be divided into two groups: static separators or cyclones and dynamic separators or high effi-

Modeling of the separation process in dynamic separators

2013年1月1日The proposed aerodynamic scheme of the separator gas tract A centrifugal fan with a sufficiently large capacity is used as a stimulator of the movement of the gas flow in the gas path of the...

US Patent for Dynamic separator for a grinding mill Patent

A dynamic separator for a grinding mill having a stator installed in a stationary manner and a rotor provided on a rotary shaft such that it faces the stator. Between the stator and the rotor is provided a small gap for the passage of processed material in order to separate and discharge the processed material from the dispersion media. The rotor is arranged

Particle size reduction, screening and size analysis Objective

Wet grinding should be considered in cases where the material is prone to static charging, or when the material is toxic and dust containment is difficult. Also wet grinding can be used when the final product size is extremely fine since production of nanoparticles is possible with wet grinding. Pigments for inks and

Dynamic separator efficiency, SEPOL, O-Sepa, Sepax etc

online cement plant live calculator for dynamic separator calculation, Efficiency on Coarse basis, fine basis, efficiency against residues of mill output separator input and return coarse material

CNU Nanoscale dynamic separating grinding miller

The utility model relates to a nanoscale grinding miller, in particular to a nanoscale dynamic separating grinding miller. The nanoscale dynamic separating grinding miller comprises a grinding tube with an internal molding grinding cavity formed inside,and a feed cavity communicated with the grinding cavity. Two ends of the grinding cavity are

Turnkey Project Solutions and Turnkey Plant Solutions Chanderpur

Dynamic Separators For best efficiency of your grinding system and better quality of your product KNOW MORE Equipment for Petrochemical Refineriesand Chemical industry Pressure Vessels (ASME U-Certified) Expertise in manufacturing pressure vessels of various materials such as Duplex steel, alloy Steel, SS317L, SS 316L, high strength

RTKM separator for coal grinding ball mills

The RTKM separator is specially designed for use with ball mills that grind coal, petcoke or charcoal. It is an energy-efficient and well-proven solution which incorporates the experience attained from over 1500 high efficiency dynamic air separators supplied by in grinding applications. The RTKM separator is the obvious choice for new

Dynamic Separator For Sand Grinding goriaindustries

Separator Optimization In Cement Mill. Aug 18, 2018 Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants.The function of the separator is to separate the fine-sized particles from the coarse-sized particles, so as to avoid material condensation and over

CFD Modeling of the High Efficiency Rotor Separator in Cement Grinding

The results proved that the RSM model better captures the phenomenon in the dynamic separator when compared with experimental results made by the Enfidha Cement plant CE. M., Hatem, M., Bournot, P. (2013). CFD Modeling of the High Efficiency Rotor Separator in Cement Grinding Circuit. In: Haddar, M., Romdhane, L., Louati, J., Ben

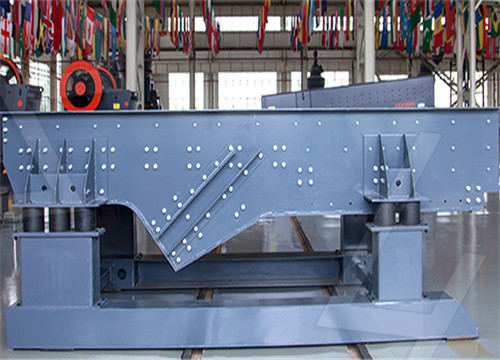

Horizontal sand mill Franli Machine

The adjustable dynamic separator used is made of high wear-resistant powder alloy, which has the characteristics of self-cleaning and adjustable gaps. Users can choose 0.1mm grinding media, which creates effective conditions for the grinding effect of the product. The working process of the FRANLI horizontal sand mill

Dynamic Separator For Sand Grinding darujzene

Dsl dynamic airflow separator the raw meal, coke and coal pro. the dynamic airflow separator dsl is used in airflow mills, and is primarily used in grinding petcoke or coal, as well as raw meal. depending on the material to be ground, it can also be used to separate other products, such as minerals, limestone, feldspar, or quartz sand.

Good Quality Large Diameter Separator Disk Type Horizontal Sand

1. Large diameter dynamic separator with large flux; 2. Adopts double mechanical seal, the lubricating liquid dissolved with material,safe and reliable; 3. Multiple material can be chosen for dispersing disc,which can meet the requirement of product aberration by clients; 4. Main body is convenient to dismantle, and it's easy to change color and clean.