Journal On Installation Of Jaw Crusher For Aggregate Production

Influence of jaw crusher parameters on the quality of

2020年6月1日This stone presents a parameter study investigating the effect of feed and jaw crusher parameters on the quality of aggregates produced from single-stage

Automated process control system of Jaw crusher

2021年12月1日The purpose of this research is to develop an automated control system for Jaw crusher production process as a solution for the real specified problems to get

Simplification of Jaw crusher for Artisanal Aggregates Miners

manually operated portable jaw-crusher (Crispin, 1997); which costs about US$ 3,000. However the crusher has a low throughput producing about one ton per day and is

Automated process control system of Jaw crusher

2021年12月1日The purpose of this research is to develop an automated control system for Jaw crusher production process as a solution for the real specified problems to get

(PDF) Production and Uses of Crushed Rock Aggregate

2021年10月3日Aggregate is a broad category of coarse to medium grained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled

Selection of the optimum in-pit crusher T location for an

a hill. They started limestone production from the new mine site and planned to move the existing crusher plant to the new quarry site. The authorities were not sure on which

journal on installation of jaw crusher for aggregate

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

journal on installation of jaw crusher for aggregate production

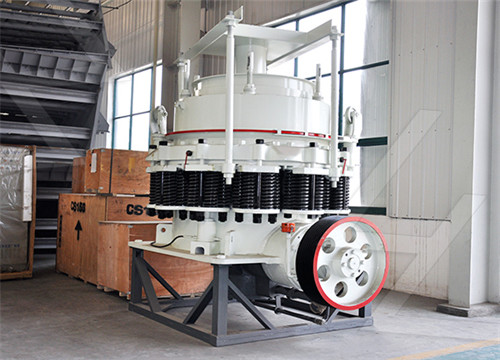

2019年6月22日Case Study of cone crusher and jaw crusher in Australia,- journal on installation of jaw crusher for aggregate production,The finished particles are can be

How to improve jaw crusher performance and productivity

2020年3月30日Apply the proper jaw die profile. There are many kinds of rocks, differing in crushability, abrasiveness, flakiness, etc. Choosing the best combination of fixed and movable jaw dies profiles will help to

Automated process control system of Jaw crusher production

2021年12月1日The purpose of this research is to develop an automated control system for Jaw crusher production process as a solution for the real specified problems to get more productive aggregate production. First a 3D model which mimic exactly the real crushing plant was built to test the proposed system.

Jaw Crusher an overview ScienceDirect Topics

The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time. This is dependent on the area of the discharge opening, the properties of the rock, moisture, crusher throw, speed, nip angle, method of feeding and the amount of size reduction.

Simplification of Jaw crusher for Artisanal Aggregates Miners

manually operated portable jaw-crusher (Crispin, 1997); which costs about US$ 3,000. However the crusher has a low throughput producing about one ton per day and is physically tasking requiring two people to operate comfortably. In this twork a simple jaw-crusher is pro-posed and developed for small-sc ale aggregate miners,

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

pulverizer. Figure 3 illustrates the angle of nip in a jaw crusher. Figure 3: Angle of nip in a jaw crusher 2.3 Crusher Jaw Plates Compression of materials undergoing crushing in a jaw crusher is achieved when the movable jaw presses the feed against a stationary jaw. These jaws can be flat surfaced or corrugated.

Automated process control system of Jaw crusher production

2021年12月1日The purpose of this research is to develop an automated control system for Jaw crusher production process as a solution for the real specified problems to get more productive aggregate...

Selection of the optimum in-pit crusher T location for an

a hill. They started limestone production from the new mine site and planned to move the existing crusher plant to the new quarry site. The authorities were not sure on which bench it would be better to install the crusher plant to keep haulage distance to a minimum, so they applied for a project to the University of Dokuz Eylul in Izmir.

Crushing Equipment Superior Industries U.S.

Liberty ® Jaw Crusher Primary Maximum Feed Size 47″ (1,194mm) Product Size 15″ 5″ (380mm 125mm) Maximum Reduction Ratio 6:1 Maximum Production Rate 1,595 STPH (1,446 MTPH) — Materials:

Konya Journal of Engineering Sciences ? Submission DergiPark

2021年4月12日The present study investigates the effects of rock crushing circuits on aggregate quality. For this purpose, a crushing screening plant located in Vize (Kırklareli, Turkey) was considered. Based on the current operating conditions, the crushing screening plant was modeled.

journal on installation of crusher for aggregate production

journal on installation of jaw crusher for aggregate,Know More. River stone jaw crushing production line layout All Purpose River Stone Jaw Crushers For Aggregate and installation,in the out and only the 150 600mm goes to the.

journal on installation of jaw crusher for aggregate production

2019年6月22日Case Study of cone crusher and jaw crusher in Australia,- journal on installation of jaw crusher for aggregate production,The finished particles are can be adjusted from 10 to 40 mm, we could get the needed aggregate through vibrating screen The full optimized scheme of stone crushing plant are PE 750 x 1060 jaw crusher,

Crushers an overview ScienceDirect Topics

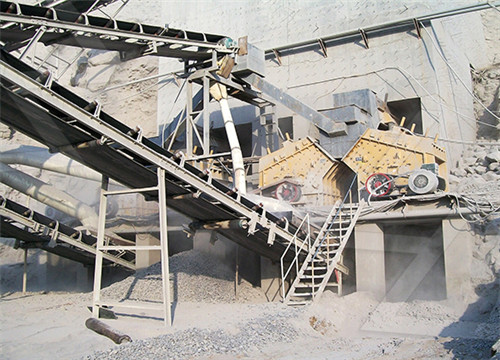

Jaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages. The crushing process takes place between a fixed jaw and a moving jaw. The moving jaw dies are mounted on a pitman that has a reciprocating motion. The jaw dies must be replaced regularly due to wear.

Jaw ModelsLiterature -Milwaukee

mpljaw crushers are fabricated with an extra-heavily ribbed steel plate construction to provide maximum strength and durability while in operation. Frames are stress relieved before machining and after

Configuration and design of 1000tph limestone aggregate production

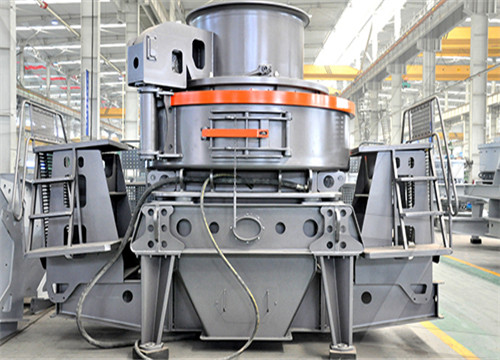

2021年10月22日The processing capacity of the production line is 1000t/h, 10% of the soil is removed, and the finished aggregate product is 20-31.5mm, 18%; 10-20 mm, 25%; 5-10 mm, 17%; 0-5 mm, 25%. Considering the requirements of rock characteristics and product proportion, choose a two-stage crushing scheme, which is jaw crusher + impact

Applied Sciences Free Full-Text The Effect of Curing Conditions

2020年6月27日The latter was prepared about 6 years before the beginning of the experiment by crushing three parent concretes with three different water-to-cement ratios. A laboratory jaw crusher was used for crushing. Next, the aggregate was separated on screens into fractions (4/6, 6/8, 8/12, and 12/16 mm) and placed in open boxes, located

Jaw Crusher an overview ScienceDirect Topics

The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time. This is dependent on the area of the discharge opening, the properties of the rock, moisture, crusher throw, speed, nip angle, method of feeding and the amount of size reduction.

Simplification of Jaw crusher for Artisanal Aggregates Miners

manually operated portable jaw-crusher (Crispin, 1997); which costs about US$ 3,000. However the crusher has a low throughput producing about one ton per day and is physically tasking requiring two people to operate comfortably. In this twork a simple jaw-crusher is pro-posed and developed for small-sc ale aggregate miners,

Crusher an overview ScienceDirect Topics

Heavy-duty primary jaw crushers are installed underground for uniform size reduction before transferring the ore to the main centralized hoisting system. Medium-duty jaw crushers are useful in underground mines with low

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

pulverizer. Figure 3 illustrates the angle of nip in a jaw crusher. Figure 3: Angle of nip in a jaw crusher 2.3 Crusher Jaw Plates Compression of materials undergoing crushing in a jaw crusher is achieved when the movable jaw presses the feed against a stationary jaw. These jaws can be flat surfaced or corrugated.

Selection of the optimum in-pit crusher T location for an

a hill. They started limestone production from the new mine site and planned to move the existing crusher plant to the new quarry site. The authorities were not sure on which bench it would be better to install the crusher plant to keep haulage distance to a minimum, so they applied for a project to the University of Dokuz Eylul in Izmir.

Jaw ModelsLiterature -Milwaukee

mpljaw crushers are fabricated with an extra-heavily ribbed steel plate construction to provide maximum strength and durability while in operation. Frames are stress relieved before machining and after welding to ensure the highest quality product. Through finite element analysis, mplengineers have been able to provide jaw crushers

Configuration and design of 1000tph limestone aggregate production

2021年10月22日The processing capacity of the production line is 1000t/h, 10% of the soil is removed, and the finished aggregate product is 20-31.5mm, 18%; 10-20 mm, 25%; 5-10 mm, 17%; 0-5 mm, 25%. Considering the requirements of rock characteristics and product proportion, choose a two-stage crushing scheme, which is jaw crusher + impact

journal on installation of crusher for aggregate production

journal on installation of jaw crusher for aggregate,Know More. River stone jaw crushing production line layout All Purpose River Stone Jaw Crushers For Aggregate and installation,in the out and only the 150 600mm goes to the.

journal on installation of jaw crusher for aggregate production

2019年6月22日Case Study of cone crusher and jaw crusher in Australia,- journal on installation of jaw crusher for aggregate production,The finished particles are can be adjusted from 10 to 40 mm, we could get the needed aggregate through vibrating screen The full optimized scheme of stone crushing plant are PE 750 x 1060 jaw crusher,

Applied Sciences Free Full-Text The Effect of Curing Conditions

2020年6月27日The latter was prepared about 6 years before the beginning of the experiment by crushing three parent concretes with three different water-to-cement ratios. A laboratory jaw crusher was used for crushing. Next, the aggregate was separated on screens into fractions (4/6, 6/8, 8/12, and 12/16 mm) and placed in open boxes, located

journal on installation of crusher for aggregate production

Journal On Installation Of Crusher For Aggregate Production. 5 aggregate and tertiary crushing, if nece ssary, are the final steps in reducing the material to a desired productly, cone and roll crushers were the most common choice crushers, but in recent years impact crushers are more widely on installation of

Aggregate Crusher Turn Stone Materials Into Building Aggregates

PE750 1060 jaw crusher Model: PE-750*1060 Feed opening size (mm): 750*1060 Max.Feeding size (mm): 630 Adjusting range of discharge opening (mm): 80-140 Processing capacity (t/h): 110-320 Rotation speed of eccentric shaft (r/min): 250 Mixing power (kw): 110 Total weight (T): 29 Dimension (L*W*H) (mm): 2660*2430*2800 Now

mill/sbm jaw crusher production line installation diagram.md at

Contribute to crush2022/mill development by creating an account on GitHub.

Jaw Crushers AGGRETEK Jaw Crushers for aggregatemining

AGGRETEK Jaw Crushers are designed for applications where cost-efficient primary reduction of hard, abrasive materials is concerned. About Us; Equipment. Crushers. AGGREGATE TECHNOLOGIES GROUP CORPORATE HEADQUARTERS 150 Isidor Ct. Suite 103 Sparks, Nevada 89441 USA WEST COAST SALES Sparks, NV +1 775-686