Crusher Development Process

Crushers an overview ScienceDirect Topics

Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer crusher based on impact.

Crusher an overview ScienceDirect Topics

Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. 13.3.1.1 Primary Crusher Primary crushers are heavy-duty rugged

进一步探索

5 Types Of Stone Crushers Application and MaintenanceTypes of Crushers Mineral ProcessingMetallurgy根据热度为您推荐•反馈

(PDF) Design and Development of Plastic Crusher for a

2020年8月31日The efficiency of crushing based on polymers processed are 90% for HDPE, 68% for LDPE, 45% for PVC and 10% for PET bottles. The developed crusher can be used to reduce the volume of plastic waste...

Principles of Mechanical Crushing MetallurgistMineral

Principles of Mechanical Crushing MetallurgistMineral Processing

What is the major step in the process of open-pit and

2023年3月10日Typically, the steps of open-pit and underground mining include 1. Exploration and assessment of the resource 2. Development of a mine plan 3. Construction of access roads 4. Drilling and...

The development process of jaw crusher stone cruxder

2022年7月8日The development process of jaw crusher. 发表评论 / Stationary Crusher / 作者: lulu. After more than 100 years of practice and improvement, the jaw crusher has no breakthrough changes in structure, but it still has the characteristics of simple structure, reliable operation, easy production, convenient maintenance, low equipment and

Crusher Quick-Start Guide — OLCF User Documentation

Slurm provides 3 ways of submitting and launching jobs on Crusher’s compute nodes: batch scripts, interactive, and single-command. The Slurm commands associated with these methods are shown in the table below and examples of their use can be

Design Project Brief Can Crusher Mfg./Environmental Sector

• performs the loading of fresh cans into the can crusher. • interfaces with the electric relay control system (operates the can crusher) to signal the start and stop of the process. • uses a pushbutton to start the process of picking up a can and loading it into the can crusher. • have a structure that: • holds the can to be crushed

Optimisation of the swinging jaw design for a single

2022年9月20日This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to the appropriate sizes for direct application or further processing. During the crushing process, large and non-evenly distributed impact forces occur,

New developments in cone crusher performance optimization

2009年6月1日Validation is therefore a rigorous process with no opportunity to “fit” data to a desired outcome. Model development and validation is an ongoing process. Parameters included in the validation exercises include crusher throughput, crusher power draw, crushing force and product size distributions. The use of the virtual comminution model

Optimisation of the swinging jaw design for a single toggle jaw crusher

2022年9月20日The crushing process occurs in stages (arrested crushing) along the crushing cavity due to the reciprocating movement of the swinging jaw in relation to the fixed jaw [ 4 ]. The required sizes of particles fall freely through the bottom adjustable crusher opening (referred to as a set) onto the sieves for grading [ 9 ].

Design and Construction of Rock Crushing Machine from

The process is required to reduce rocks and lumps to smaller pieces. Rollers or jaw crushers are employed in this situation. The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one in relative motion against the other which is stationary while the

Development of an automatic can crusher using

2019年6月1日PLC -HMI interface using the NB-Designer software from OMRON shows how the Automatic Can Crusher complete its task with showing how many can it have crush. The desired size of Nescafe brand

Design and Development of a Plastic Bottle Crusher IJERT

Abstract—A crusher is a machine designed to reduce large solid material objects into a smaller volume, or smaller pieces. Crushers may be used to reduce the size, or change the form, of materials so they can be more easily and efficiently used in the purpose intended to. Crushing is the process of transferring a

Design and Development of a Plastic Bottle Crusher IJERT

2014年10月14日Fabrication of the bottle crusher was divided into 4 stages. It consists of the fabrication of base structure, its components, transmission system and the reciprocating system. The different processes followed in the fabrication of these components is elaborated under the following heads Fabrication of Base Structure

Design and experimental research on the counter roll differential

Because of the problems that the current solid organic fertilizer is easy to agglomerate in the fermentation and stacking process, the fertilizer efficiency is brutal to release, and the strip application is difficult to discharge, this stone proposes a solid organic fertilizer crushing strip application method combining propeller blades and differential speed rollers.

Crusher Quick-Start Guide — OLCF User Documentation

Slurm provides 3 ways of submitting and launching jobs on Crusher’s compute nodes: batch scripts, interactive, and single-command. The Slurm commands associated with these methods are shown in the table below and examples of their use can be

IJERPH Free Full-Text Platinum Mine Workers’ Exposure to Dust

2020年1月19日The South African mining industry is one of the largest producers of platinum (Pt) in the world. Workers in this industry are exposed to significant amounts of dust, and this dust consists of particles sizes that can penetrate deep inside the respiratory region. A cross-sectional study was conducted to evaluate dust exposure risk at two Pt

MetallurgistMineral Processing Engineer

MetallurgistsMineral Processing Engineers. 11 Metallurgist has a clear understanding of what successful mineral processing engineering is and how to go about achieving it. Your goal is the production of a material that is marketable and returns you and your investors sustainable revenues. Although improvements to the metallurgical processes

VWHPRI-DZFUXVKHU SURGXFWLRQ Institute of Physics

2021年6月14日crusher production process as a solution for the real specified problems to get more productive aggregate production. First a 3D model which mimic exactly the real crushing plant was built to development in the construction and building industry, there is 145 of investment in the field of building

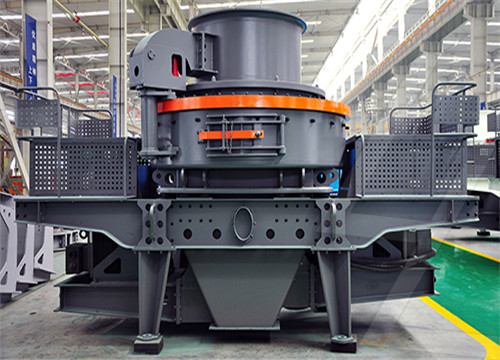

Impact Crushers Design And Calculations

Impact Crushers Design And Calculations Impact crusher in the production process, the main parameters of the equipment has an important significance for normal operation, generally includes three basic parameters: the rotor speed, productivity and motor power.

crusher development cs github

crusher development cs. the development of jaw crusher Crusher the development of jaw crusher.Jaw crusher,Portable mobile Crusher,Cone Crusher.CS series spring cone crusher is

Tertiary roll crusher development. Interim report (Technical

This report describes the development of the roll crusher used for crushing Fort-St.Vrain type fissile and fertile fuel particles, and large high-temperature gas-cooled reactor (LHTGR) fissile fuel particles. The entire pilot plant process consists of crushing the fuel elements to a size suitable for burning in a fluidized bed to remove

New developments in cone crusher performance optimization

2009年6月1日Validation is therefore a rigorous process with no opportunity to “fit” data to a desired outcome. Model development and validation is an ongoing process. Parameters included in the validation exercises include crusher throughput, crusher power draw, crushing force and product size distributions. The use of the virtual comminution model

Design and Construction of Rock Crushing Machine from

The process is required to reduce rocks and lumps to smaller pieces. Rollers or jaw crushers are employed in this situation. The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one in relative motion against the other which is stationary while the

Development of an automatic can crusher using

2019年6月1日The invention of a can crusher machine in this project is to reduce the wasted storage space occupied by the tremendous amount of use aluminium can at the commercial establishment like in the...

Design and Development of a Plastic Bottle Crusher IJERT

Abstract—A crusher is a machine designed to reduce large solid material objects into a smaller volume, or smaller pieces. Crushers may be used to reduce the size, or change the form, of materials so they can be more easily and efficiently used in the purpose intended to. Crushing is the process of transferring a

Design and Development of a Plastic Bottle Crusher IJERT

2014年10月14日Fabrication of the bottle crusher was divided into 4 stages. It consists of the fabrication of base structure, its components, transmission system and the reciprocating system. The different processes followed in the fabrication of these components is elaborated under the following heads Fabrication of Base Structure

Design and experimental research on the counter roll differential

Because of the problems that the current solid organic fertilizer is easy to agglomerate in the fermentation and stacking process, the fertilizer efficiency is brutal to release, and the strip application is difficult to discharge, this stone proposes a solid organic fertilizer crushing strip application method combining propeller blades and differential speed rollers.

Crusher Quick-Start Guide — OLCF User Documentation

Slurm provides 3 ways of submitting and launching jobs on Crusher’s compute nodes: batch scripts, interactive, and single-command. The Slurm commands associated with these methods are shown in the table below and examples of their use can be

IJERPH Free Full-Text Platinum Mine Workers’ Exposure to Dust

2020年1月19日The South African mining industry is one of the largest producers of platinum (Pt) in the world. Workers in this industry are exposed to significant amounts of dust, and this dust consists of particles sizes that can penetrate deep inside the respiratory region. A cross-sectional study was conducted to evaluate dust exposure risk at two Pt

Vertical Shaft Turnings Crusher Market [2023-2026] Visionary

2023年3月8日Mar 08, 2023 (The Expresswire) -- Pre and Post-Covid Report Is Covered Final Report Will Add the Analysis of the Impact of Russia-Ukraine War and COVID-19...

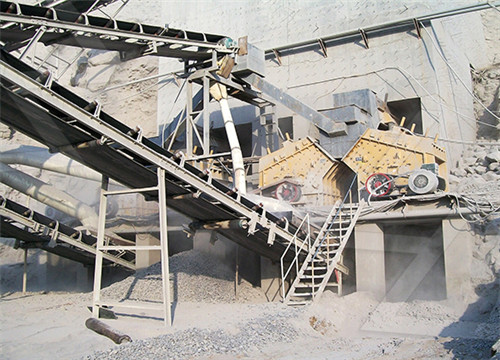

Crushers decide the development of mining industry

Crusher equipment industry needs to develop continually, needs to meet the customers' requirements continually. In the process of urbanization and industrialization of highway, rail, water conservancy and other major infrastructure investment is increasing, which will increase the large demand for the crusher equipment.

MetallurgistMineral Processing Engineer

MetallurgistsMineral Processing Engineers. 11 Metallurgist has a clear understanding of what successful mineral processing engineering is and how to go about achieving it. Your goal is the production of a material that is marketable and returns you and your investors sustainable revenues. Although improvements to the metallurgical processes

Computer Modeling Process Minnesota Department of Agriculture

Computer Modeling Process. The MDA’s development of N leaching reduction strategies with modeling in Drinking Water Supply Management Areas (DWSMAs) is a multi-step process. The generalized process is outlined below using simple management and N leaching values as an example. Deviations from this process may occur based on

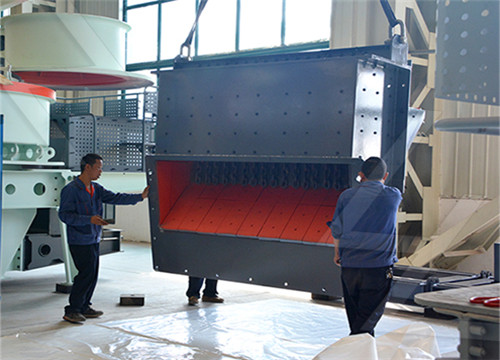

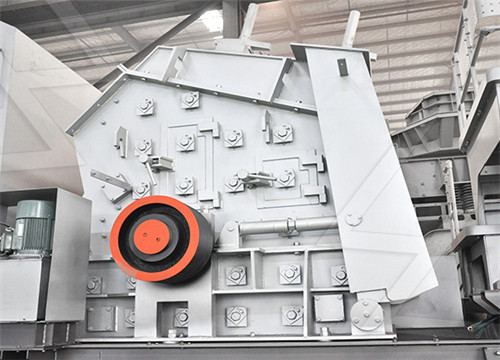

Development of Impact Crusher in Home and Aboard kara liu

2012年9月4日Development of Impact Crusher in Home and Aboard. In the late fifties,our country has already designed the crusher,in the eighties, the domestic impact crusher s are limited to process coal and limestone, and the other kinds of hard materials. until the former construction machinery factory introduced the KHD type hard rock impact crusher

Development of AISI A2 Tool Steel Beater Head for an Impact Crusher

2015年3月7日Failure analysis of a tool steel (AISI A2) beater head of an impact crusher and development of suitable heat treatment process to improve its performance have been presented. The beater heads were failing prematurely by brittle fracture from its pin-hole locations. The investigation consisted of visual inspection, fractography, chemical