Maschines In Process Recover Copper Tailings

Statistical investigation of flotation parameters for copper

2021年3月1日A brief statistical analysis has shown that froth flotation is a reliable process to recover copper from flotation tailings. • Collector dosage remains the main

Development of Copper Recovery Process from Flotation

2018年3月1日In this study, a novel SO2 removal process using copper tailings coupled with copper recovery was proposed, a pilot-scale device was set up, and an economic

The Challenges and Prospects of Recovering Fine Copper Sulfides

2022年5月6日For recovering copper from tailings, regrinding is needed to liberate copper minerals from locked grains. As a result, liberated but fine copper mineral

Mine tailings: reprocess, recoverrecycle The

2019年9月13日By reprocessing tailings, dewatering them and then storing them in a dry stack, mines can remove some of the economic, environmental and societal risks

From Tailings to Treasure? A New Mother Lode

2015年5月7日New technology allows it to recover up to 40% of the gold left in particle form in tailings. DRD Gold extracted 33,600 ounces of gold, worth nearly US$40 million, in the last quarter of 2013. Mintails, a mine

New Tailings Reprocessing Technology Has

2020年10月6日Several efforts are underway to extract gold and copper from tailings. Reprocessing mine tailings may also have environmental benefits. A recent project described in Mining is a series of

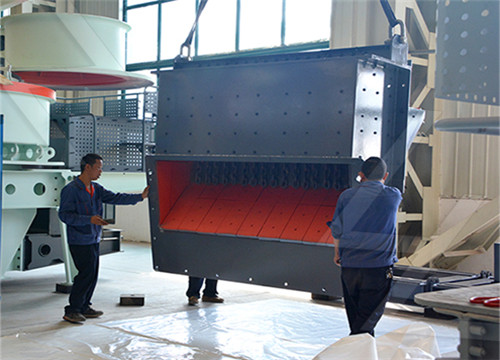

Hydrocyclones Upgrade Tailings Treatment Process

2019年11月7日Hydro cyclone improve tailings enrichment and recovery rate. The average grades of copper and gold in copper tailings are: 0.07%, 0.08g/t, the content is low, and the size of the inlay is fine, but due to the

Stepwise Utilization Process to Recover Valuable

2021年2月17日In this , a stepwise extraction process was proposed to recover valuable elements (copper, iron, lead and zinc) from waste copper slag. The specific

Development of copper recovery process from flotation

2018年6月15日Development of copper recovery process from flotation tailings by a combined method of high‒pressure leaching‒solvent extraction Development of copper

Development of copper recovery process from flotation tailings

2018年6月15日A new flotation tailings treatment process was developed for efficient Cu recovery. • An efficient Cu dissolution was achieved in an H 2 O media in presence of pyrite.. The dissolution mechanism of CuFeS 2 has been confirmed to be a multistage reaction.. Fe was always co-dissolved with Cu following a linear relation of C Fe = 38.393

Development of copper recovery process from flotation tailings

2018年6月15日SO 2 removal and copper tailings disposal became a challenge for the cleaner production of copper smelter. In this study, a novel SO 2 removal process using copper tailings coupled with copper recovery was proposed, a pilot-scale device was set up, and an economic evaluation was conducted. Effects of factors including temperature,

Minerals Free Full-Text Recovery of Copper from Leached

2020年1月6日One of the techniques of solid–liquid separation that processes solutions with low concentrations of metals corresponds to adsorption, and more recently biosorption, which is based on the use of biological matrices that do not constitute an environmental liability after application.

Development of Copper Recovery Process from Flotation Tailings

2018年3月1日Copper is traditionally obtained through the extraction of natural ore deposits, predominantly chalcopyrite (CuFeS 2 ) and chalcocite (Cu 2 S), and subsequent processing by pyro-and...

The Challenges and Prospects of Recovering Fine Copper Sulfides

2022年5月6日For recovering copper from tailings, regrinding is needed to liberate copper minerals from locked grains. As a result, liberated but fine copper mineral particles are formed. This necessitates the development of flotation techniques to recover fine copper mineral particles from tailings.

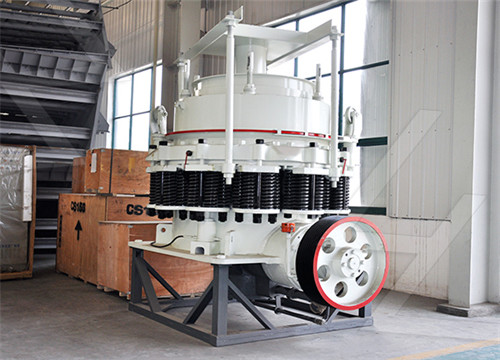

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

2023年3月7日Copper accounts for 46% of all mine tailings globally, followed by gold at 21% and iron at 9%. Countries with large numbers of tailings dams include Australia, Brazil, Canada, and the United States.

Innovative Methodology for Sulfur Release from

2020年7月15日To comprehensively reuse copper ore tailings, the recovery of γ-Fe 2 O 3 from magnetic roasted slag after sulfur release from copper ore tailings followed by magnetic separation is performed.

Recovery of rutile from a porphyry copper tailings sample

Application of thermal neutron capture-gamma ray analysis to oxidized taconite beneficiation process slurries / by Franklin B. W. Woodbury. Monitoring taconite process streams with thermal neutron capture-gamma ray analysis / by Franklin B.W. Woodbury.

Development of copper recovery process from flotation tailings

2018年6月1日@article{Han2018DevelopmentOC, title={Development of copper recovery process from flotation tailings by a combined method of high‒pressure leaching‒solvent extraction.}, author={Baisui Han and Batnasan Altansukh and Kazutoshi Haga and Zoran Stevanovi{\'c} and Radojka Jonovic and Ljiljana Avramovi{\'c} and Daniela Uro{\vs}evi{\'c}

A Review of Nickel, Copper, and Cobalt Recovery by Chelating Ion

2018年11月9日Copper and cobalt can be found on nickel laterite ores, and cobalt can be found also on copper ores, and many contaminants such as iron, aluminum, and magnesium are associated with these ores. In hydrometallurgical process, a purification step is necessary after leaching due to the presence of these impurities. Chelating resins

A New Technique for Recovering Copper From Complex Copper

2018年9月24日The copper recovery rate of the magnetic separation concentrates was 28.44%, the magnetic separation copper tailings accounted for 26.95%, resulting in a total copper recovery rate of 87.61%, which maximized the recovery of copper resources.

RECOVERY OF VALUES FROM A PORPHORY COPPER

from the deportment data that is plotted alongside the recovery data in Figure 1. This data was collected from operating plants where samples from the tailings stream were analyzed on a size-by-size basis. As shown, a significant amount of value still remains in the tailings in the finest and coarsest size fractions.

Managing Tailings More Sustainability FEECO International Inc.

As a leader in waste transformation, FEECO continues to be a valuable resource for those looking to reuse or recover their tailings through feasibility testing and process development services. Factors Influencing Tailings Management

Development of copper recovery process from flotation tailings

2018年6月15日A new flotation tailings treatment process was developed for efficient Cu recovery. • An efficient Cu dissolution was achieved in an H 2 O media in presence of pyrite.. The dissolution mechanism of CuFeS 2 has been confirmed to be a multistage reaction.. Fe was always co-dissolved with Cu following a linear relation of C Fe = 38.393

Development of copper recovery process from flotation tailings

2018年6月15日SO 2 removal and copper tailings disposal became a challenge for the cleaner production of copper smelter. In this study, a novel SO 2 removal process using copper tailings coupled with copper recovery was proposed, a pilot-scale device was set up, and an economic evaluation was conducted. Effects of factors including temperature,

Minerals Free Full-Text Recovery of Copper from Leached

2020年1月6日One of the techniques of solid–liquid separation that processes solutions with low concentrations of metals corresponds to adsorption, and more recently biosorption, which is based on the use of biological matrices that do not constitute an environmental liability after application.

Development of Copper Recovery Process from Flotation Tailings

2018年3月1日Copper is traditionally obtained through the extraction of natural ore deposits, predominantly chalcopyrite (CuFeS 2 ) and chalcocite (Cu 2 S), and subsequent processing by pyro-and...

Ftmmachinery Has Made a Breakthrough in Mineral Beneficiation

2023年3月7日Copper accounts for 46% of all mine tailings globally, followed by gold at 21% and iron at 9%. Countries with large numbers of tailings dams include Australia, Brazil, Canada, and the United States.

The Challenges and Prospects of Recovering Fine Copper Sulfides

2022年5月6日For recovering copper from tailings, regrinding is needed to liberate copper minerals from locked grains. As a result, liberated but fine copper mineral particles are formed. This necessitates the development of flotation techniques to recover fine copper mineral particles from tailings.

Recovery of rutile from a porphyry copper tailings sample

Application of thermal neutron capture-gamma ray analysis to oxidized taconite beneficiation process slurries / by Franklin B. W. Woodbury. Monitoring taconite process streams with thermal neutron capture-gamma ray analysis / by Franklin B.W. Woodbury.

Development of copper recovery process from flotation tailings

2018年6月1日@article{Han2018DevelopmentOC, title={Development of copper recovery process from flotation tailings by a combined method of high‒pressure leaching‒solvent extraction.}, author={Baisui Han and Batnasan Altansukh and Kazutoshi Haga and Zoran Stevanovi{\'c} and Radojka Jonovic and Ljiljana Avramovi{\'c} and Daniela Uro{\vs}evi{\'c}

Innovative Methodology for Sulfur Release from

2020年7月15日To comprehensively reuse copper ore tailings, the recovery of γ-Fe 2 O 3 from magnetic roasted slag after sulfur release from copper ore tailings followed by magnetic separation is performed.

A Review of Nickel, Copper, and Cobalt Recovery by Chelating Ion

2018年11月9日Copper and cobalt can be found on nickel laterite ores, and cobalt can be found also on copper ores, and many contaminants such as iron, aluminum, and magnesium are associated with these ores. In hydrometallurgical process, a purification step is necessary after leaching due to the presence of these impurities. Chelating resins

Selective Process Route to Recover Magnetite from Chalcopyrite

2022年9月28日This suggests, copper could be recovered from non-magnetic cleaner tailings, which corresponds to 4% of copper fed in flotation tailings. Considering the three steps, that is, screen classification, rougher, and cleaner magnetic separation, the total mass recovery is 3.02% (3.02% = 6.33% × 47.69%) and Fe and SiO 2 recoveries were

Recovery of cobalt and copper through reprocessing of tailings

2013年12月1日DOI: 10.1016/J.JECE.2013.08.025 Corpus ID: ; Recovery of cobalt and copper through reprocessing of tailings from flotation of oxidised ores @article{Lutandula2013RecoveryOC, title={Recovery of cobalt and copper through reprocessing of tailings from flotation of oxidised ores}, author={Michel Shengo

Managing Tailings More Sustainability FEECO International Inc.

As a leader in waste transformation, FEECO continues to be a valuable resource for those looking to reuse or recover their tailings through feasibility testing and process development services. Factors Influencing Tailings Management

RECOVERY OF VALUES FROM A PORPHORY COPPER

from the deportment data that is plotted alongside the recovery data in Figure 1. This data was collected from operating plants where samples from the tailings stream were analyzed on a size-by-size basis. As shown, a significant amount of value still remains in the tailings in the finest and coarsest size fractions.