Quartz Slica Powder Production Chart

Quartz mining and processing flow chart at selected

As a mineral resource, due to its stable physical chemistry properties, quartz has a wide range of uses, such as silica glass, silica ceramics, silicon metal in the semiconductor field, solar

Silica Sand Products, High Purity Quartz Sand, low Iron

根据热度为您推荐•反馈

AP-42, CH 11.7: Ceramic Products Manufacturing

powder mixing, or by spray drying. Spray dryers generally are gas-fired and operate at temperatures of 110° to 130°C (230° to 270°F). 11.7.2.3 Mixing The purpose of mixing

manufacturing flowchart of quartz powder github

Contribute to jidafang2022/en development by creating an account on GitHub.

Quartz powder Silica Flour Manufacturers and Suppliers

Quartz Silica Chemical specification: SiO₂ 98% 99.9%. LOI 0.5 2%. Whiteness 88% 97%. Fe₂O₃ 0.04% 1% (As per requirement) Ec :- 5>510 Quartz Powder/ Filler Uses. Quartz is used in various Industries

en/silicon oxide making for quartz powder process.md at

Contribute to jidafang2022/en development by creating an account on GitHub.

Crystalline Silica Cancer-Causing Substances NCI

2019年2月1日Quartz is the most common form of crystalline silica. What is crystalline silica? An abundant natural material, crystalline silica is found in stone, soil, and sand. It is also found in concrete, brick, mortar, and

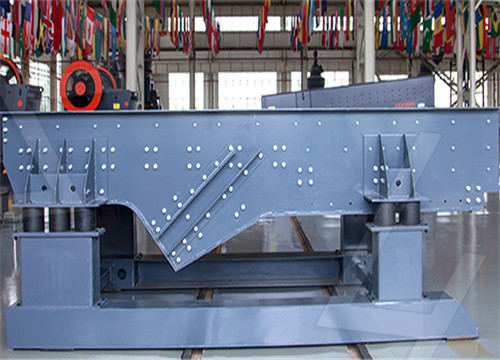

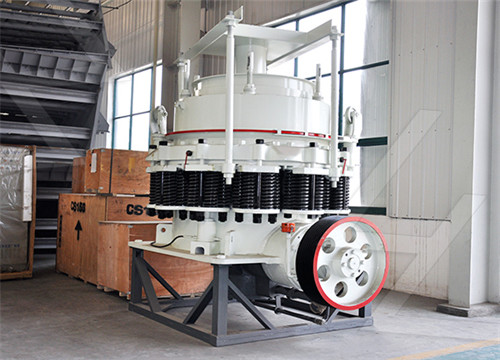

Quartz production line flow chart_BAILING® Machinery

SiO 2 ≥97.62%,Fe 2 O 3 ≤0.24,Al 2 O 3 ≤1.11%. After transformation. Screening classification dry magnetic separation Dosing strong scrub acid leaching process. SiO 2 ≥99.4%,Fe 2 O 3 ≤0.052,Al 2 O 3

quartz slica poudre production graphique-quartz slica powder

quartz slica powder production chart As a leading global manufacturer of crushing grinding and mining equipments we offer advanced reasonable solutions for any

Silica Statistics and Information U.S. Geological Survey

Statistics and information on the worldwide supply of, demand for, and flow of the mineral commodity silica. Industrial sand and gravel, often called "silica," "silica sand," and "quartz sand," includes sands and gravels with high silicon dioxide (SiO 2) content. These sands are used in glassmaking; for foundry, abrasive, and hydraulic

Influence of quartz powder and silica fume on the performance

2020年12月8日Both silica fume and quartz powder increase the carbonation depth of the composites. A. E. M.Auda, E. M. Re-use of waste marble dust in the production of cement and concrete. Constr. Build

Silica (Sio2) an overview ScienceDirect Topics

Silica (SiO 2) is a starting material for silicon, which is sand or quartz.The removal of oxygen or reducing silica to silicon is a key processing step in silicon production. Fig. 3.3 shows the different methods used to reduce the silica to silicon. MG-Si is the starting material to produce pure silicon for PV and electronics applications.

Fused quartz silica powder / Cristobalite production YouTube

2018年1月15日Silica powder / fused silica / cristobalite for Silica Sol Investment Casting(Casting refractory applications) High heat temperature and heat shrinkage...

manufacturing flowchart of quartz powder github

Contribute to jidafang2022/en development by creating an account on GitHub.

U.S. SILICA COMPANY SAFETY DATA SHEET

known as tridymite; if crystalline silica (quartz) is heated to more than 1470°C, quartz can change to a form of (physical state, color, etc.): White or tan sand: granular, crushed or ground to a powder. Odor: None. Odor threshold: Not determined pH: 6-8 Melting point/freezing point: 3110°F/1710°C Boiling point/range: 4046°F/2230°C

en/silicon oxide making for quartz powder process.md at main

Contribute to jidafang2022/en development by creating an account on GitHub.

Quartz powder in India Silica powder manufacturers and

Quartz/Silica Powder. TMM India is manufacturing and exporting Quartz powder in different grades for various Industrial uses. TMM is manufacturing Grade A quartz powder with high brightness of around 98% and high whiteness of 95% plus with confirmation of product quality through Rasin test in all the lots produced.

Quartz production line flow chart_BAILING® Machinery

SiO 2 ≥97.62%,Fe 2 O 3 ≤0.24,Al 2 O 3 ≤1.11%. After transformation. Screening classification dry magnetic separation Dosing strong scrub acid leaching process. SiO 2 ≥99.4%,Fe 2 O 3 ≤0.052,Al 2 O 3

Silica dust Cancer Council

The most common form is quartz. Silica dust can also be found in the following products: bricks tiles concrete some plastic material. When these materials are worked on, silica is released as a fine dust known as

Silica Silicon Dioxide (SiO2) AZoM

2001年12月13日Ceramic grade sand is less than 75μm and has a silica content above 97.5%, impurities include <0.55% Al 2 O 3 and <0.2 Fe 2 O 3. It is used in the production of glazes and ceramic materials. Foundry Sand Foundry sand is produced at particle size of less than 75μm.

Materials Free Full-Text Lightweight Reactive Powder Concrete

This stone presents the test results of the lightweight concrete properties obtained by adding expanded perlite (EP) to an RPC mix in quantities from 30% to 60% by volume of the concrete mix. It has been shown that in these cases it is possible to obtain concrete containing 30% by volume with density of approximately 1900 kg/m3 and the

The Use of Engineered Silica to Enhance Coatings

A summary of the main methods for producing synthetic silica is shown in Figure 1. The most common types of silica used in modern coatings are produced either by a liquid phase process of precipitation or gas phase process of flame hydrolysis.

Silica Statistics and Information U.S. Geological Survey

Statistics and information on the worldwide supply of, demand for, and flow of the mineral commodity silica. Industrial sand and gravel, often called "silica," "silica sand," and "quartz sand," includes sands and gravels with high silicon dioxide (SiO 2) content. These sands are used in glassmaking; for foundry, abrasive, and hydraulic

Silica (Sio2) an overview ScienceDirect Topics

At low temperature, silica forms the so-called α -quartz phase; on heating, this transforms into β -quartz, then HP-tridymite, and then β -cristobalite before melting at 1727 °C. These are all phases with slightly different crystal structures. If cooled quickly or under pressure, yet more phases appear including, on fast cooling, the glass phase.

Silica Silicon Dioxide (SiO2) AZoM

2001年12月13日Ceramic grade sand is less than 75μm and has a silica content above 97.5%, impurities include <0.55% Al 2 O 3 and <0.2 Fe 2 O 3. It is used in the production of glazes and ceramic materials. Foundry Sand Foundry sand is produced at particle size of less than 75μm.

Precision casting zirconium zirconium powder preferred

2018年1月15日The same shell mold surface area and the amount of fused silica powder (sand) Shell shell cost, to the surface layer of sand instead of fused quartz sand, slurry surface to zirconium powder mixed

Fused quartz silica powder / Cristobalite production YouTube

2018年1月15日Silica powder / fused silica / cristobalite for Silica Sol Investment Casting(Casting refractory applications) High heat temperature and heat shrinkage...

U.S. SILICA COMPANY SAFETY DATA SHEET

known as tridymite; if crystalline silica (quartz) is heated to more than 1470°C, quartz can change to a form of (physical state, color, etc.): White or tan sand: granular, crushed or ground to a powder. Odor: None. Odor threshold: Not determined pH: 6-8 Melting point/freezing point: 3110°F/1710°C Boiling point/range: 4046°F/2230°C

en/silicon oxide making for quartz powder process.md at main

Contribute to jidafang2022/en development by creating an account on GitHub.

Quartz powder in India Silica powder manufacturers and

Our Quartz powder is widely used in cement Industries for concrete slab manufacturing. SizesGrade Our Silica (Quartz) Powder Specifications Grade A Packing 50 kg new pp bags with Inner lining, 1 ton Jumbo bags with inner lining, 1.45 MT

Quartz production line flow chart_BAILING® Machinery

SiO 2 ≥97.62%,Fe 2 O 3 ≤0.24,Al 2 O 3 ≤1.11%. After transformation. Screening classification dry magnetic separation Dosing strong scrub acid leaching process. SiO 2 ≥99.4%,Fe 2 O 3 ≤0.052,Al 2 O 3

Materials Free Full-Text Lightweight Reactive Powder Concrete

This stone presents the test results of the lightweight concrete properties obtained by adding expanded perlite (EP) to an RPC mix in quantities from 30% to 60% by volume of the concrete mix. It has been shown that in these cases it is possible to obtain concrete containing 30% by volume with density of approximately 1900 kg/m3 and the

The Use of Engineered Silica to Enhance Coatings

A summary of the main methods for producing synthetic silica is shown in Figure 1. The most common types of silica used in modern coatings are produced either by a liquid phase process of precipitation or gas phase

flowchart on mining industryquartz powder transakt.online

2022年6月22日Quartz. Quartz is the second most abundant mineral on Earth's crust. A wide variety of high grade Quartz that we are offering is appreciated for its resistance against mechanical and chemical weathering. Quartz (Silica SiO2) is the most common mineral in the Earths crust. Quartz is found in sandstones, pegmatites granites, and

slag powder production process flow chart github

Contribute to lbsid/en development by creating an account on GitHub.

Quartz vs. Fused Silica: What are the Differences? AZoM

2021年8月4日Fused Silica and Fused Quartz The word “fused” here refers to a processing step: fused silica is nominally pure silica that has been melted and cooled to form a glassy, amorphous solid. Fused silica does not contain any additives while still resembling other glasses in many ways.

- 磷矿开采要求

- 立式沙袋价格

- Screening Equipment For Ore Minerals

- South African Iron Mining Equipment Supplier

- Small Hammer Mill Manufacturers Bangalore

- 磁性皮带输送机

- Cement Mill Gearbox Cement Plant And Heavy Duty Gearboxe

- 水磨粉是什么

- 每小时产750T冲击式制砂机

- China Best Diesel Engine Jaw Crusher With Ce

- 山林开采石头

- css175破碎机

- 铁路vsi5x9532制砂机

- 超级文件粉碎机 win7

- 滨州锤式粉碎机代理-矿石设备厂家价格