Beneficiation Plant Concentrate Bin Manufacturer

Gold Processing Plant Prominer (Shanghai) Mining

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are

Phosphate Beneficiation Florida Poly

Phosphate Beneficiation. Definition of “Beneficiation”: This is the second step in the mining process, after removal of the ore from the ground. Beneficiation is the technical

进一步探索

Phosphate Beneficiation Process Mineral ProcessingBeneficiation technology of phosphates: challenges and 根据热度为您推荐•反馈

Beneficiation Plants and Pelletizing Plants for Utilizing

plant before being charged into a blast furnace. Pellet feed: Pellet feeds have diameters smaller than approximately 0.15mm and are agglomerated by a pelletizing plant before

Iron Ore Beneficiation Process MetallurgistMineral

2017年4月27日At this time four of the above methods of beneficiation, i. e., Drying, Screening, Log Washing, and Table Concentration are in use,

Phosphate Beneficiation Process Mineral Processing

The Phosphate Beneficiation FlowsheetRecovery of PhosphateThe Flowsheet For Phosphate BeneficiationPhosphate Beneficiation

Phosphate Ore MiningElectrically operated drag lines strip off the overburden from the mining area and deposit the phosphate matrix around a pump pit. Here it is sluiced with streams of high pressure water to the suction of a large centrifugal pump which transports the matrix slurry to the washing plant whicWashing and Screening Phosphate RockAt the washer the water-matrix slurry discharges into a surge receiving bin or tub and is screened for removal of clay, sand and fine phosphate from the mud balls. The screen oversize passes through a hammer mill to break down the mud balls and occasional large pebbles. The screen u在911metallurgist上查看更多信息预计阅读时间:11 分钟

11.21 Phosphate Rock Processing US EPA

fertilizer manufacture consists of beneficiation, drying or calcining at some operations, and grinding. The Standard Industrial Classification (SIC) code for phosphate rock processing

Ilmenite: An Ore of Titanium Beneficiation and Plant

2023年2月15日Ilmenite beneficiation process Tests have shown that you had better use the combined beneficiation process of gravity separation, magnetic separation, and

fr/phosphate rock beneficiation plant concentré bin.md at

Contribute to liyingliang2022/fr development by creating an account on GitHub.

phosphate rock beneficiation plant concentrate bin

Phosphate Rock Beneficiation Plant Concentrate Bin. Figure 1—Typical phosphate losses in Florida Great effort is spent by the phosphate industry to beneficiate the rock to

Iron Ore Beneficiation Primetals Technologies

Mineral processing is the cornerstone of efficient and sustainable steel production and essential to providing a high-quality raw material for the metallurgical production chain. As a life-cycle partner in the global iron

11.21 Phosphate Rock Processing US EPA

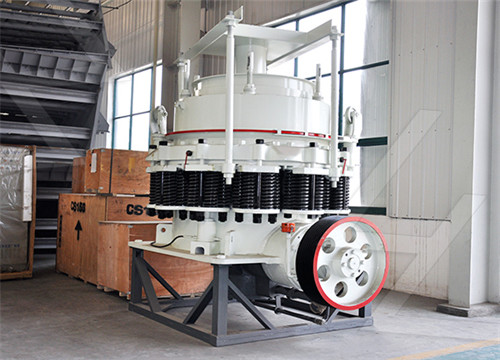

fertilizer manufacture consists of beneficiation, drying or calcining at some operations, and grinding. The Standard Industrial Classification (SIC) code for phosphate rock processing is 1475. depending on the phosphoric acid plant requirements. Primary size reduction generally is accomplished by crushers (impact) and grinding mills

Manganese Ore Processing Mineral ProcessingMetallurgy

2016年4月27日The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers. The mine run ore is dumped through a 10″ grizzly into a coarse ore bin. The ore is discharged by a Apron Feeder to feed the primary Jaw Crusher.

LOW-INTENSITY MAGNETIC SEPARATION: PRINCIPAL STAGES

concentrate bin, was first suggested in 1870. In 1884 a stationary magnetic system incompletely covering an internal drum surface was applied. Magnetic material was More recently, most iron-ore beneficiation plants employed magnetic separators that were developed during the 1950s [4,5]. Modernization of these machines during the last

Coons-Pacific Iron Ore Concentrator Eveleth, MN

2015年11月6日The first step in all beneficiation plants is converting crude ore into a medium that can be effectively fed into a concentrator. This generally involves some degree of primary crushing, as well as screening or classifying the ores into sizes either oversized or minus-grade and undersized ores which were amenable to concentration.

Small Mineral Processing Plant Design / Construction

2016年3月18日The twin concentrate bins are raised high enough to afford clearance for a truck and are emptied through the bottom by means of removable floor sections. All heavy mill equipment is set on reinforced concrete foundations carried down to solid bearing. Lighter machinery is supported on frame substructure.

researchgate.net

The current methods of separation in the beneficiation plants are wet low intensity magnetic separation (WLIMS) and reverse apatite flotation, where the WLIMS stage is regarded as the crucial part

Belt Conveyor for OresConcentrate in Beneficiation Plant

SKE can provide belt conveyor system for all types of ore dressing methods. Now matter using the ways of flotation, magnetic, gravity,or heap leaching separating, we can help you build conveyor system. If you need ore beneficiation plant conveyor system, you can leave me your messages via our email and inquiry box.

Welcome to Environment

Beneficiation plantpelletization plant of 0.85 MTPA0.6 MTPA respectively with 10MW power plant. Now, the company wants to get the Environmental Clearance for enhancing the DRI sent to the Concentrate Bin. The filter water will be recycled back. The waste water from of M/s Masco Plexus Private Limited with the aim of manufacturing

Estimated Water Requirements for the Conventional Flotation

immediately available for reuse in the beneficiation plant because it has been used in the production of backfill slurry from tailings to provide underground mine support; because it has been entrapped in the concentrate circuit ranges from roughly 1.5 metric tons (t) to about 3.5 t of water to process 1 t of ore [Wels and Robertson, 2003

Mineral Processing an overview ScienceDirect Topics

Mineral processing, also known as ore dressing, mineral beneficiation, or mineral engineering, is defined as the science and art of separating valuable metallic and nonmetallic minerals from unusable gangues. From: Mineral Exploration (Second Edition), 2018 View all Topics Add to Mendeley About this page Mineral Processing

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日Magnetic separation is used to remove large quantities of iron bearing gangue minerals to make the concentrate suitable for use in ceramics and glass manufacturing. These separation techniques will be reviewed in the following sections. Download : Download high-res image (135KB) Download : Download full-size image

Mineral Beneficiation Plants Latest Price From Top Manufacturers

Find mineral beneficiation plants manufacturers, suppliers, dealerslatest prices from top companies in India. Buy from a wide range of mineral beneficiation plants online.

phosphate rock beneficiation plant concentrate bin

Phosphate Rock Beneficiation Plant Concentrate Bin. Figure 1—Typical phosphate losses in Florida Great effort is spent by the phosphate industry to beneficiate the rock to obtain a concentrate containing 30 31 P 2 O 5 [1] During this process much of the phosphate values are lost to the tailings stream .

Iron Ore Beneficiation Primetals Technologies

Mineral processing is the cornerstone of efficient and sustainable steel production and essential to providing a high-quality raw material for the metallurgical production chain. As a life-cycle partner in the global iron

Gold Processing Plant Prominer (Shanghai) Mining

These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the

Chromite Beneficiation Process Mineral Processing

2016年4月12日Chromite Grinding. The 36″x 8′ Adjustable Stroke Ore Feeder is used to accurately control feed of crushed ore to the grinding section. Before it is fed to the 4’x 8′ Peripheral Discharge Rod Mill, the

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日Magnetic separation is used to remove large quantities of iron bearing gangue minerals to make the concentrate suitable for use in ceramics and glass manufacturing. These separation techniques will be reviewed in the following sections. Download : Download high-res image (135KB) Download : Download full-size image

Small Mineral Processing Plant Design / Construction

2016年3月18日The twin concentrate bins are raised high enough to afford clearance for a truck and are emptied through the bottom by means of removable floor sections. All heavy mill equipment is set on reinforced

researchgate.net

The current methods of separation in the beneficiation plants are wet low intensity magnetic separation (WLIMS) and reverse apatite flotation, where the WLIMS stage is regarded as the crucial part

Belt Conveyor for OresConcentrate in Beneficiation Plant

SKE can provide belt conveyor system for all types of ore dressing methods. Now matter using the ways of flotation, magnetic, gravity,or heap leaching separating, we can help you build conveyor system. If you need ore beneficiation plant conveyor system, you can leave me your messages via our email and inquiry box.

Welcome to Environment

Beneficiation plantpelletization plant of 0.85 MTPA0.6 MTPA respectively with 10MW power plant. Now, the company wants to get the Environmental Clearance for enhancing the DRI sent to the Concentrate Bin. The filter water will be recycled back. The waste water from of M/s Masco Plexus Private Limited with the aim of manufacturing

sbm/sbm slate beneficiation plant manufacturer.md at main

Contribute to chengxinjia/sbm development by creating an account on GitHub.

LOW-INTENSITY MAGNETIC SEPARATION: PRINCIPAL

concentrate bin, was first suggested in 1870. In 1884 a stationary magnetic system More recently, most iron-ore beneficiation plants employed magnetic separators that were developed during the

Mineral Beneficiation Plants Latest Price From Top Manufacturers

Find mineral beneficiation plants manufacturers, suppliers, dealerslatest prices from top companies in India. Buy from a wide range of mineral beneficiation plants online.

Ore Processing Mineral Beneficiation Plant Manufacturer from

Manufacturer of Ore Processing Mineral Beneficiation Plant, Pellet Plant, Sponge Iron Plant offered by B M M Ispats, Bengaluru, Karnataka. IndiaMART. Get Best Price. X. B M M Ispats. 10 Museum Road, Bengaluru, Karnataka.

Iron Ore Beneficiation Plant ManufacturersSuppliers in India

Iron Ore Benefication Plant ₹ 2.5 Crore/ Piece Get Latest Price Design: Customized Material: M.S, Casting, copper, Stainless Steel Capacity: 5-100 ton per hour Power: 200-1000 K.W Driven Type: 3-6 months Voltage: 440 read more Shalimar Engineering Bakrol, Ahmedabad TrustSEAL Verified Company Video View Mobile Number

Review of tungsten resource reserves, tungsten concentrate

2022年7月1日Trans. Nonferrous Met. Soc. China 32(2022) 2318−2338 Review of tungsten resource reserves, tungsten concentrate production and tungsten beneficiation technology in China Xu WANG1, Wen-qing QIN1,2, Fen JIAO1,2, Liu-yang DONG1, Jian-gen GUO3, Jian ZHANG3, Cong-ren YANG1,2 1.