Quiotation For Operation Amp3b Maintenace Of Crusher Plant

quiotation for operation maintenace of crusher plant

Contribute to luoruoping/id development by creating an account on GitHub.

ANALYSIS OF FAILURE STATISTICS FOR CONE CRUSHER

correction of problems. The model will contribute to improve the maintenance indicators and based on the consequences, decisions may be taken to promote the plant’s

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR

of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job. The failures of these equipments have led to high maintenance and operation

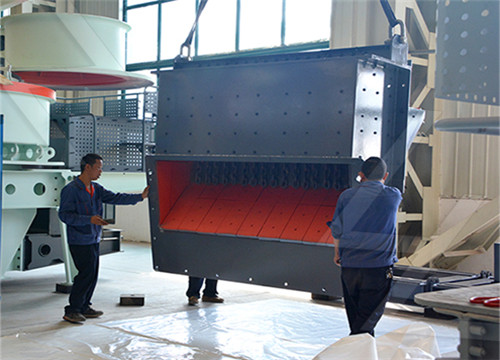

Crushing Plant Installation, Operation and Maintain JXSC

Preparation For InstallationOperating NotesKey Points of MaintenanceProduction Safety System

The higher usage frequency machine is crushing equipment in the crusher production plant. To ensure higher production efficiency and longer service life, plant manufacturers must do a good job of maintenance. 1. Dearing maintenance Bearing parts of crushing equipment is more easily damaged. Making sure the service life of bearings needs to add lubr...

quiotation for operation maintenace of crusher plant

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Construction Working and Maintenance of Crushers for

Construction Working and Maintenance of Crushers for Crushing Bulk

quiotation for operation maintenace of crusher plant

quiotation for operation amp maintenace of crusher plant manager jobs opencast Crushing Plant Engineer. operation of portable or permanently mounted quiotation

Crusher Operating Costs: How to Optimize and Reduce

2016年1月10日It is assumed that power is charged to the plant at the rate of 0.75d. per kilowatt-hour in the case of the smallest plant, decreasing as the capacity increases to a minimum of 0.5d. per kw.-hr. for the largest.

quiotation for operation amp maintenace of crusher plant

Industry News. quiotation for operation maintenace of crusher plant . cone crusher operation Quarry Plant Infomation in India. . quiotation for operation. quiotation

Quiotation For Operation Maintenace Of Crusher Plant

how to install a crusher plant indonesia coal crusher manufacturer. We will send detail technical info and quotation to you! possible, equipment manufacturers should be

quiotation for operation maintenace of crusher plant

Contribute to luoruoping/id development by creating an account on GitHub.

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure. Predictive means using historical service life data to determine when a machine

ANALYSIS OF FAILURE STATISTICS FOR CONE CRUSHER

correction of problems. The model will contribute to improve the maintenance indicators and based on the consequences, decisions may be taken to promote the plant’s maintenance strategy and improving crusher reliability. THE EQUIPMENT Cone crushers are extensively used for rock breakage and as a secondary crusher or tertiary crusher in a

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job. The failures of these equipments have led to high maintenance and operation costs. The reason for inspection depends on the component and its effect on plant operation. But one of the main systems of thermal power plant is coal-handling system.

Reliability and maintainability analysis of crushing plants

Serial Correlation Test For PRCS of Crushing plant 2 0 70 140 210 0 70 140 210 ( i 1 ) th. TBF i th. TB F Figure 2. The serial correlation test for SCRCS and COCS of crushing plant 2 4.2. Analysis of data with trend The TBF data set for PSCCS and SSCCS of the two crushing plants exhibit presence of trends in trend test so the

quiotation for operation maintenace of crusher plant

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

Factors affecting the performance of crushing plant operations

2014年1月1日Crushing plants have been of great interest in reducing the particle size of ores milling operations need to consider sustainable development. Since the crushing plants are operated under severe

FIELD MONITORING AND PERFORMANCE EVALUATION OF

In this , factors that affect the performance of the crushing plant operation are evaluated by focusing several critical design parameters associated with downtimes and production losses. It also provides the operational, instrumental, mechanical and maintenance aspects of crushing plant. Specific objectives are: i) to get detailed

CPCCDE3013A Operate a crushing plant training.gov.au

CPCCDE3013A Operate a crushing plant Modification History Not Applicable Unit Descriptor Unit descriptor This unit of competency specifies the outcomes required to operate a crushing plant to provide various size ranges of crushed materials. This unit includes the preparation, inspection, maintenance, operation and shut down of a

Crushing Plant FlowsheetDesign-Layout Mineral

2016年3月10日For proper operation, the crusher always operates with a choke level in the cavity. A controlled feed race permitting a constant power draw is required for an efficient circuit. Through proper application of the

training.gov.au RIIPRO201A Conduct crushing operations

1. Plan and prepare for operations. 1.1. Access, interpret and apply compliance documentation relevant to the conduct of crushing operations. 1.2. Obtain, interpret and clarify work requirements for the satisfactory completion of operations. 1.3. Select and use personal protective equipment appropriate for work activities. 1.4.

Preventive crusher and screen maintenance Metso Outotec

Preventive maintenance technology explained with Metso Metrics. Metso Metrics technology for aggregates customers helps monitor, maintain and manage clients’ assets. Connected equipment is ensured by many advanced sensors installed on each plant, tracking various elements around the performance of the machine. An intuitive interface

Operation and Maintenance of Coal Handling System in Thermal Power Plant

2011年1月1日Operation and Maintenance of Coal Handling System in Thermal Power Plant [J].Colliery Machine;2011, 32 (2):201-204. ss door, not attached to the machine or climbing machines, to avoid danger. b9 lubrication of coal crusher Bearing lubrication is an important part of coal crusher, the oil should be 1 / 2 to 2 / 3 is appropriate of the oil

Operation and Maintenance of Coal Handling System in Thermal Power Plant

2011年12月31日Reduction of Auxiliary Power of In-house HT Equipment in Thermal Power Plant by Energy Conservation. January 2015. Rajashekar P. Mandi. Udaykumar R Yaragatti. This stone describes the results of

quiotation for operation maintenace of crusher plant

Contribute to luoruoping/id development by creating an account on GitHub.

Avoid Unplanned Downtime: 5 Crusher Maintenance Best

There are three approaches to maintenance: reactive, preventative and predictive. Reactive is repairing something that has failed. Preventative maintenance is often viewed as unnecessary but minimizes downtime because the machine is getting repaired before failure. Predictive means using historical service life data to determine when a machine

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

of Critical Equipments for Coal Handling Plants (CHP) of Thermal Power Stations is typical job. The failures of these equipments have led to high maintenance and operation costs. The reason for inspection depends on the component and its effect on plant operation. But one of the main systems of thermal power plant is coal-handling system.

Factors affecting the performance of crushing plant operations

2014年1月1日Crushing plants have been of great interest in reducing the particle size of ores milling operations need to consider sustainable development. Since the crushing plants are operated under severe

quiotation for operation maintenace of crusher plant

Contribute to kokiulinjsb/ru development by creating an account on GitHub.

FIELD MONITORING AND PERFORMANCE EVALUATION OF

In this , factors that affect the performance of the crushing plant operation are evaluated by focusing several critical design parameters associated with downtimes and production losses. It also provides the operational, instrumental, mechanical and maintenance aspects of crushing plant. Specific objectives are: i) to get detailed

CPCCDE3013A Operate a crushing plant training.gov.au

CPCCDE3013A Operate a crushing plant Modification History Not Applicable Unit Descriptor Unit descriptor This unit of competency specifies the outcomes required to operate a crushing plant to provide various size ranges of crushed materials. This unit includes the preparation, inspection, maintenance, operation and shut down of a

training.gov.au RIIPRO201A Conduct crushing operations

1. Plan and prepare for operations. 1.1. Access, interpret and apply compliance documentation relevant to the conduct of crushing operations. 1.2. Obtain, interpret and clarify work requirements for the satisfactory completion of operations. 1.3. Select and use personal protective equipment appropriate for work activities. 1.4.

Quiotation For Operation Maintenace Of Crusher Plant

how to install a crusher plant indonesia coal crusher manufacturer. We will send detail technical info and quotation to you! possible, equipment manufacturers should be encouraged to stock and provide spare parts close to the mining operation. The Installation and Maintenance of Mobile Crushing Plant. View Details Send Enquiry Vehicle Fleet

Preventive crusher and screen maintenance Metso

Preventive maintenance technology explained with Metso Metrics. Metso Metrics technology for aggregates customers helps monitor, maintain and manage clients’ assets. Connected equipment is ensured by many

Operation and Maintenance of Coal Handling

2011年12月31日Reduction of Auxiliary Power of In-house HT Equipment in Thermal Power Plant by Energy Conservation. January 2015. Rajashekar P. Mandi. Udaykumar R Yaragatti. This stone describes the results of

Operation and Maintenance of Coal Handling System in Thermal Power Plant

2011年1月1日Operation and Maintenance of Coal Handling System in Thermal Power Plant [J].Colliery Machine;2011, 32 (2):201-204. ss door, not attached to the machine or climbing machines, to avoid danger. b9 lubrication of coal crusher Bearing lubrication is an important part of coal crusher, the oil should be 1 / 2 to 2 / 3 is appropriate of the oil

DESIGN OF MECHANICAL CRUSHING MACHINE IRJET

electrical types of operation. 2. WORKING PRINCIPLE The crusher is designed to operate on a crank and slotted lever mechanism and the power for the electrical operation of the crusher is taken from an electrical motor. It is designed to use a 3 phase induction motor for the electrical operation of the crusher as the power required