Flowchart Of Copper Floating Equipment

1 Froth Flotation Fundamental Principles

This means that 95.7% of the copper present in the ore was recovered in the concentrate, while the rest was lost in the tailings. (c) The % Cu Loss can be calculated by subtracting

Flotation data for the design of process plants Part 2 case

Case study one: a complex copper, lead and zinc flotation circuit (the Hellyer Project) The Hellyer Project was developed by Aberfoyle Limited and proceeded from discovery in

进一步探索

Flotation data for the design of process plants Part 1 Tes(PDF) Scale up and design of flotation circuits Research根据热度为您推荐•反馈

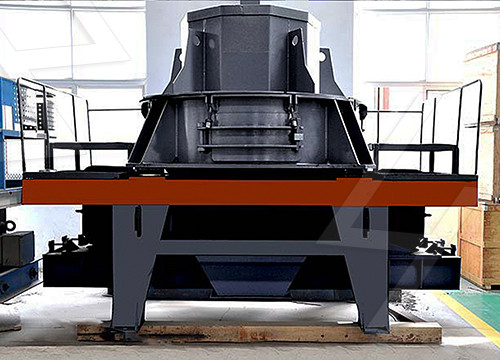

Copper Processing Equipment, Process Flow, Cases

2019年8月23日According to the metallurgy process, the copper ore is divided into three natural types by the ratio of copper oxide and copper sulfide. That is, sulfide ore,

Copper Process Flowsheet Example Mineral

2015年10月1日Copper Process Flowsheet Example. A simplified schematic drawing of copper flotation flowsheet. Run-of-mine open pit

Copper Flotation Mineral ProcessingMetallurgy

2016年5月16日Copper Flotation. Although basic porphyry copper flotation and metallurgy has remained virtually the same for many years, the processing equipment as well as design of the mills has continually

181 Process Flow Diagram (PFD) Symbols for Engineers

Process Flow Diagram equipment symbols include centrifuges and heat exchangers. Centrifuges Centrifuges are devices that use centrifugal force/ acceleration to separate

Copper Float Valves: Types, Applications and Materials

2015年4月1日Generally, copper floats are made up of three unique pieces: A copper valve An arm or lever A copper float In these systems, the float valve is a sturdy copper piece connected to a bronze arm. The

The Tin Plating Process: A Step-By-Step Guide

Tin Plating Process Elements. Tin can be electrodeposited onto just about any type of metal. Let’s take a closer look at the specific components of an effective tin plating process: 1. Cleaning: It is vital to purify the substrate

FLOTAC 2023

FLOTAC 2023. Happening in Viña del Mar, Chile, from March 30 to 31, FLOTAC is Chile's premier flotation conference where we will be showcasing our Jameson Cell technology. We are proud sponsors of this event, so be sure to stop by our booth to talk flotation. Our Central and South American Sales Director, Christian Pasten, and Jameson Cell

Copper electroplating fundamentals DuPont

2016年11月22日The concept of copper electroplating is straightforward: Submerge the wafer to be plated into an electrolyte bath, apply a current, and copper ions will migrate and deposit onto regions with a pre-existing

Copper Artifacts Milwaukee Public Museum

It was undoubtedly from these pieces of metal that much of the artifacts from the Old Copper Complex were manufactured. Here are examples of float copper found in Wisconsin, as well as some examples of nodules hammered into modified pre-forms. Great Lakes native copper is typically more than 95% pure.

The Float Process Step-by-step Pilkington

The Step-by-step Manufacturing of Float Glass Watch the magic of this science-based process begins to unfold, in a series of stages on a float line that may be nearly half a kilometre long. Raw materials enter at one end. From the other, plates of glass emerge, cut precisely to specification, at rates as high as 6,000 tonnes a week.

️ 4 Most Common Types of Flowcharts + Templates| Gliffy

2019年12月11日4 Most Common Types of Flowcharts. While the variations and versions of flowcharts are endless, four flowchart types are particularly popular and very versatile — the process flowchart, the workflow chart, the swimlane flowchart, and the data flowchart. These four common types are great for describing business, manufacturing,

Float Equipment Forum Energy Technologies, Inc.

Forum’s standard design float shoes and float collars are manufactured with the PVTS valve. This valve is a spring-actuated, plunger-type, one-way check valve. It is designed to withstand high temperatures and large volumes of fluids pumped at high flow rates. It also provides an effective seal under both high- and low-pressure conditions

GPM Chart for Copper and PEX Pipe SupplyHouse

GPM Chart for CopperPEX Pipe Tubing Size/Type Minimum Flow Rate1 (gpm) Maximum Flow Rate2 (gpm) 3/8” Copper 1.0 2.0 1/2” Copper 1.6 3.2 3/4” Copper 3.2 6.5 1” Copper 5.5 10.9 1.25” Copper 8.2 16.3 1.5” Copper 11.4 22.9 2”

Copper Tubes Pressure Loss vs. Water Flow Engineering ToolBox

Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140oF, 60oC ). If water temperatures routinely exceeds 140oF don't exceed 2-3 ft/s (0.6-0.9 m/s). Pressure losses are calculated with the Hazen-Williams equation and a roughness coefficient c = 145.

Water Flow Rate CalculatorWater Treatment Equipment Sizing

Sizing Whole-House Water Filter Cartridge Systems. Whole House Filter Cartridge Systems can restrict the water flow if the inappropriate size is chosen. Choose the size that accomodates your estimated service flow. Flows up to 6 gpm: 10" Big Blue Cartridge Fitler Systems. Flows up to 10 gpm: 20" Big Blue Cartridge Fitler Systems.

What is a Workflow Diagram Lucidchart

Flowchart: A flowchart is the actual chart that illustrates your workflow. Flowcharts are used to depict a variety of concepts, including workflows. Business process mapping: Think of workflow as a simple, step-by-step, linear process with no optimization.

Float Equipment Weatherford International

Drive casing to total depth and prevent cement flowback. Our comprehensive selection of float equipment―including float shoes and float collars―facilitate proper cementing for any well environment from unconventional to deepwater. These field-proven tools deliver a secure primary cement job and reduce the chances of remedial operations.

Beginners guide to thickeners Metso Outotec

2017年6月16日The measurable parameters that can be used for thickener control include thickener feed flow rate, feed density, underflow density, overflow clarity, bed level, bed mass, rake torque, rake height, solids settling rate and underflow rehology. Rake torque

Mining 101 Learn How It's Done Eagle Mine

As the magma cooled, nickel and copper minerals crystallized into a solid ore body. The bottom of the ore body sits roughly 3,000 feet deep and measures to be roughly 6 acres in size. the minerals attach to the bubbles and float to the surface, where they are skimmed off. Both the nickel and copper float off together, and then the nickel is

FLOTAC 2023

FLOTAC 2023. Happening in Viña del Mar, Chile, from March 30 to 31, FLOTAC is Chile's premier flotation conference where we will be showcasing our Jameson Cell technology. We are proud sponsors of this event, so be sure to stop by our booth to talk flotation. Our Central and South American Sales Director, Christian Pasten, and Jameson Cell

Copper electroplating fundamentals DuPont

2016年11月22日The concept of copper electroplating is straightforward: Submerge the wafer to be plated into an electrolyte bath, apply a current, and copper ions will migrate and deposit onto regions with a pre-existing

Copper Artifacts Milwaukee Public Museum

It was undoubtedly from these pieces of metal that much of the artifacts from the Old Copper Complex were manufactured. Here are examples of float copper found in Wisconsin, as well as some examples of nodules hammered into modified pre-forms. Great Lakes native copper is typically more than 95% pure.

The Float Process Step-by-step Pilkington

The Step-by-step Manufacturing of Float Glass Watch the magic of this science-based process begins to unfold, in a series of stages on a float line that may be nearly half a kilometre long. Raw materials enter at one end. From the other, plates of glass emerge, cut precisely to specification, at rates as high as 6,000 tonnes a week.

️ 4 Most Common Types of Flowcharts + Templates| Gliffy

2019年12月11日A flowchart is a diagram that shows each step or progression of a process in sequential order. It uses lines to indicate directional flow and a standard set of symbols to describe the step-by-step procedures, inputs, and decisions in the process.

Float Equipment Forum Energy Technologies, Inc.

Forum’s standard design float shoes and float collars are manufactured with the PVTS valve. This valve is a spring-actuated, plunger-type, one-way check valve. It is designed to withstand high temperatures and large volumes of fluids pumped at high flow rates. It also provides an effective seal under both high- and low-pressure conditions

GPM Chart for Copper and PEX Pipe SupplyHouse

GPM Chart for CopperPEX Pipe Tubing Size/Type Minimum Flow Rate1 (gpm) Maximum Flow Rate2 (gpm) 3/8” Copper 1.0 2.0 1/2” Copper 1.6 3.2 3/4” Copper 3.2 6.5 1” Copper 5.5 10.9 1.25” Copper 8.2 16.3 1.5” Copper 11.4 22.9 2”

Copper Tubes Pressure Loss vs. Water Flow Engineering ToolBox

Water velocity in copper tubes should not exceed 8 ft/s (2.4 m/s) for cold water and 5 ft/s (1.5 m/s) for hot water (up to approximately 140oF, 60oC ). If water temperatures routinely exceeds 140oF don't exceed 2-3 ft/s (0.6-0.9 m/s). Pressure losses are calculated with the Hazen-Williams equation and a roughness coefficient c = 145.

Flowchart of Extraction of Copper by Maddie Clancy Prezi

2014年2月28日Flowchart of Extraction of Copper from Chalcopyrite Ores Sulphur dioxide Gas The chemical compund with the formula SO2 Iron Silicate Slag, which is removed Sulphuric acid Copper Sulphide A mixture of metal oxides and silicon dioxide A strong mineral acid with the formula H2SO4 A family of chemical compounds and

Water Flow Rate CalculatorWater Treatment Equipment Sizing

Sizing Whole-House Water Filter Cartridge Systems. Whole House Filter Cartridge Systems can restrict the water flow if the inappropriate size is chosen. Choose the size that accomodates your estimated service flow. Flows up to 6 gpm: 10" Big Blue Cartridge Fitler Systems. Flows up to 10 gpm: 20" Big Blue Cartridge Fitler Systems.

Float Equipment Weatherford International

Our comprehensive selection of float equipment―including float shoes and float collars―facilitate proper cementing for any well environment from unconventional to deepwater. These field-proven tools deliver a secure primary cement job and reduce the chances of remedial operations.

Flowchart of the copper production from sulfide minerals

The copper production industry generates several waste effluents that contain valuable elements, among them, antimony, bismuth, iron, lead and arsenic [4,5].

Mining 101 Learn How It's Done Eagle Mine

Conventional crushing, grinding, flotation, and pressing are used to process run-of-mine ore into separate nickel and copper concentrates. Road haul trucks arrive at the mill and dump their load in the enclosed Coarse Ore Storage Area. Each truckload weighs on average between 40-45 tonnes.