Cement Mill Plant Layout Vibrating Screen Opening Specifications

Full range of BRU Vibrating Screens

The BRU Vibrating Screen is designed with durability and ease of use as a central focus. And, by improving performance and throughout, you can enjoy better throughput for your

进一步探索

Dry Vibrating Screens for mining and industrial Download information about our products and solutions I FL根据热度为您推荐•反馈

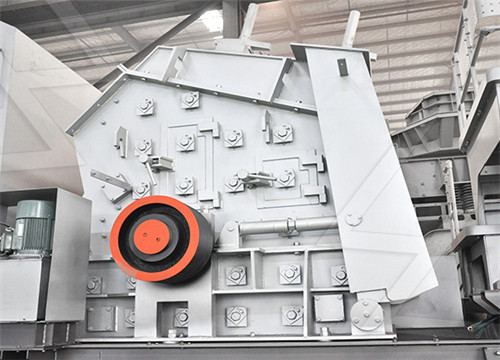

Linear Vibrating Screen Vibrating Screen Machine In Cement Plant

In the cement industry, linear vibrating screen is an important cement making machine. It has high bearing capacity, low noise, high screening efficiency, and convenient

Vibrating Screen Machine Vibrating Screen In Cement Plant

This method increases the output of cement mill by about 30% and saves electricity by about 18%, so it is adopted by many cement production enterprises. To ensure the

Vibrating Screen Working Principle Mineral Processing

IntroductionNamingMechanismApplicationsPurposeCauseUseSpecificationsSafetyOperationAssessmentCriticismsAnalysisExampleAdvantagesConstructionTypesDesign

The Type 70 Screen is usually made 4 ft. wide and from 5 to 10 ft. in length. For the rough work described above it can be relied upon to give a capacity of 4 to 5 tons per square foot when screening to about ½ in. and set at a slope of 25 to 30 degrees to the horizontal. The Type 50 Vibrator requires about 2 h.p. for its operation. Generally, manu...

Vibrating Screen Vibrating Screen Machine AGICO CEMENT

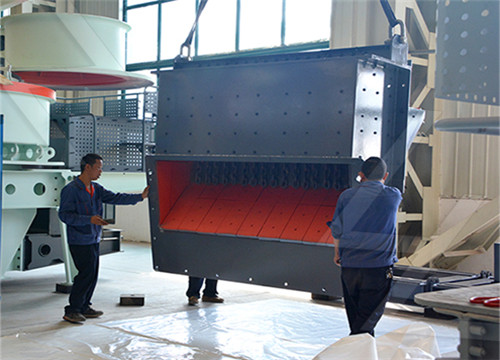

Cement clinker vibrating screen adopts a two-layer screen: coarse and fine screen, which has the advantages of high screening efficiency, quick slag discharge, long life, low

Linear vibrating screen AGICO Cement Plant

Linear vibrating screen Production Capacity: 10-600 t/h Feeding size: ≤200-≤300 mm Application: river pebbles, granite, basalt, iron ore, limestone, quartz stone, coal gangue,

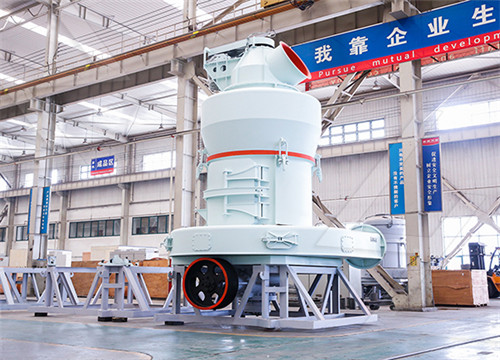

BASIC CEMENT PLANT LAYOUT

2020年4月7日16. Cement Mill and Bag House. Clinker, along with additives, is ground in a cement mill. The output of a cement mill is the final product viz. Cement. In a

Vibrating Screen Cement Plant Equipment Star Trace Pvt. Ltd.

Vibrating Screens for Cement Plants, Star Trace offers turnkey solutions for cement plants. Vibrating Screens. Cement Plant Equipment; Vibrating Screens; Get Quote Instantly

mill/sbm cement vibrating screen handbook.md at main

Contribute to crush2022/mill development by creating an account on GitHub.

Vibrating Screen Machine Vibrating Screen In Cement Plant

This method increases the output of cement mill by about 30% and saves electricity by about 18%, so it is adopted by many cement production enterprises. To ensure the particle size of the clinker is less than 5mm, we usually equip a vibrating screen between the fine crusher and the cement mill to screen and re-crush the clinker particles above 5mm.

Vibrating Screen Vibrating Screen Machine AGICO CEMENT

Cement clinker vibrating screen adopts a two-layer screen: coarse and fine screen, which has the advantages of high screening efficiency, quick slag discharge, long life, low energy consumption, small volume, lightweight, reliable use, easy installation and maintenance, vibration-damping spring are very convenient and so on.

Digitization and the future of the cement plant McKinsey

2020年9月16日There’s never been a more important time to build resilience into the core of the cement value chain: the cement plant. The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 Paul

Linear vibrating screen AGICO Cement Plant

Linear vibrating screen Production Capacity: 10-600 t/h Feeding size: ≤200-≤300 mm Application: river pebbles, granite, basalt, iron ore, limestone, quartz stone, coal gangue, construction waste, etc. !

Layout under Circular Vibrating Screen Machine and Matters

2021年12月7日1. When the vibrating screen is selected for screening equipment, the height between the center line and the floor can generally be equal to or slightly less than the width size of the screening machine. The screening machine should be equipped with a protective cover. The structure of the dust cover must be convenient for replacing the

Vibrating Screen Cement Plant Equipment Star Trace Pvt. Ltd.

Vibrating Screens for Cement Plants, Star Trace offers turnkey solutions for cement plants. Vibrating Screens. Cement Plant Equipment; Vibrating Screens; Get Quote Instantly Rigid and vibrating resistance screen body. Our Other Links. vibrating design exporters globally india screen manufacturers sale plant suppliers tamilnadu. Sitemap.

Vibrating Screen for Cement Plant YouTube

About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features Press Copyright Contact us Creators

BASIC CEMENT PLANT LAYOUT

2020年4月7日In a cement mill, there is a cylindrical shell lying horizontal which contains metallic balls and as it rotates, the crushing action of the balls helps in grinding the clinker to a fine powder. The term baghouse is applied to large filters containing a number of tubular bags mounted in a usually rectangular casing.

Specifications for Installation of Piezometers and Monitoring

Procedures and Specifications Procedure: 7 Revision: 5 Specifications for Installation of Piezometers and Monitoring Wells Page: 4 of 22 5.2 Construction Materials, continued • Stainless steel screen: continuous wire-wound non-clogging stainless steel with threaded couplings. Diameter, slot width and screen diameter will vary based

Vibrating Screen Design Specification-vibrating Screen

Vsma screen calc method aggflow dmvsma screen calc method aggflow dmTitle vsma screen calc method author bryan created date 122012 114556 am, vibrating screen design specification

mill/sbm cement vibrating screen handbook.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

Vibrating Screen|Screening Machines|Henan Pingyuan Mining

Rotary vibrating screen is designed as a high-precision screening machinery. It is composed of vertical motor,and eccentric weight installed at two ends. Get Quote Dewatering Screen Dewatering screen consists of screen cloth, vibration exciter, supporting system and motor. It is widely used in coal industry, ore industry, electricity

Vibrating Feeder Industrial Vibrating Feeder AGICO Cement

Vibrating Feeder Model: GZG,ZSW Capacity: 80t/h 1000t/h Specification 650x2500mm 1500x5600mm SEND INQUIRY What Is Vibrating Feeder The vibrating feeder is a kind of equipment that can feed block and granular materials uniformly and continuously from the storage silo to the receiving device.

Driving sustainable productivity

delivers sustainable productivity to the global mining and cement industries through market-leading engineering, equipment and service solutions Laboratory software and quality optimisation for your cement plant Process and machine control Multiple Vibrating Screen goovi®

How To Size and Select a Vibrating Screen for an Aggregate

2022年2月15日Vibratory Screens come in a variety of sizes. They can range from 4’ to 12’ wide and 6’ to 32’ long. The width of the screen determines the carrying capacity of the screen deck, while the length of the screen determines the overall efficiency of the screen. Typically, the length of the screen is 2.5 to 3 times the size of the width.

Vibrating Screen Vibrating Screen Machine AGICO CEMENT

Cement clinker vibrating screen adopts a two-layer screen: coarse and fine screen, which has the advantages of high screening efficiency, quick slag discharge, long life, low energy consumption, small volume, lightweight, reliable use, easy installation and maintenance, vibration-damping spring are very convenient and so on.

mill/sbm cement vibrating screen handbook.md at main crush2022/mill

Contribute to crush2022/mill development by creating an account on GitHub.

Digitization and the future of the cement plant McKinsey

2020年9月16日There’s never been a more important time to build resilience into the core of the cement value chain: the cement plant. The cement industry is being hit hard by the COVID-19 pandemic, with global demand for cement expected to decline by 7 to 8 percent in 2020—though these declines have been unevenly distributed across regions. 1 Paul

Layout under Circular Vibrating Screen Machine and Matters

2021年12月7日1. When the vibrating screen is selected for screening equipment, the height between the center line and the floor can generally be equal to or slightly less than the width size of the screening machine. The screening machine should be equipped with a protective cover. The structure of the dust cover must be convenient for replacing the

Principles of Screening and Sizing MetallurgistMineral

Principles of Screening and Sizing MetallurgistMineral Processing

Vibrating Screen for Cement Plant YouTube

About Press Copyright Contact us Creators Advertise Developers Terms Privacy PolicySafety How YouTube works Test new features Press Copyright Contact us Creators

Vibrating Screen Cement Plant Equipment Star Trace Pvt. Ltd.

Vibrating Screens for Cement Plants, Star Trace offers turnkey solutions for cement plants. Vibrating Screens. Cement Plant Equipment; Vibrating Screens; Get Quote Instantly Rigid and vibrating resistance screen body. Our Other Links. vibrating design exporters globally india screen manufacturers sale plant suppliers tamilnadu. Sitemap.

BASIC CEMENT PLANT LAYOUT

2020年4月7日In a cement mill, there is a cylindrical shell lying horizontal which contains metallic balls and as it rotates, the crushing action of the balls helps in grinding the clinker to a fine powder. The term baghouse is applied to large filters containing a number of tubular bags mounted in a usually rectangular casing.

Vibrating Screen Design Specification-vibrating Screen

Vsma screen calc method aggflow dmvsma screen calc method aggflow dmTitle vsma screen calc method author bryan created date 122012 114556 am, vibrating screen design specification

Stacker And Reclaimer Cement Plant Parts

Capacity: 1.45t/m3, 0.85t/m3, 1.2t/m3 or customization. Type: circular and rectangular Application: limestone, coal and etc. get price! The stacker and reclaimer is the pre-homogenization system in the cement plant. As a necessary part of the cement production line, it can concurrently or respectively complete the stacking and reclaiming.

Driving sustainable productivity

delivers sustainable productivity to the global mining and cement industries through market-leading engineering, equipment and service solutions Laboratory software and quality optimisation for your cement plant Process and machine control Multiple Vibrating Screen goovi®

screen cement vibrating gitemalin.fr

cement mill plant layout vibrating screen opening specifications Raw Mill Raw Mill In Cement Plant hotcrusher Raw Mill Is Widely Used In Cement Plant Raw mill is the key equipment for secondary grinding after crushing And it is suitable for grinding all kinds of ores and other materials no matter wet grinding or dry grinding .

sbm/sbm vibrating screen opening specifications.md at main

Contribute to changjiangsx/sbm development by creating an account on GitHub.

- 山西粉煤灰加工移动式破碎站的多少钱

- Cs 4 Ft Cone Crusher Manual

- 中型粉碎机F220

- 什么是砂、石有机杂质

- Washing Machine Beneficiation

- 北流市裕兴机械厂

- Old Steel Mill Machinery For Sale India

- 移动机伶是什么

- Gravity Separation Machine Gold Ore High Efficiency Concentrator

- 民房的建筑垃圾破碎机设备

- 流动破碎机

- 石料场3ya1548振动筛

- Flow Chart Of How Iron Ore Is Manufactured

- 连锁采矿命令

- 普通硅酸盐水泥