Manganese Ore Processing Technology

Hydrometallurgical Processing of Manganese

2011年1月1日 Effects of the mass ratio of manganese ore to sawdust, roasting temperature and time, leaching temperature and time, leaching

Manganese Mining and Processing: Everything

2022年8月1日 The Manganese Mining Process. More than 25 million tons of manganese are mined every year. Most manganese mining occurs in

Advances in mineral processing technologies related to

2020年1月1日 Li T. Technology of low grade pyrolusite ore reduction process and recent advances. China’s Manganese Industry 2008; 26: 4–13. Search in Google Scholar. Li Y,

Research Progress in Process Technology for Manganese

The present conditions and distribution characteristic of manganese ore resources at home and abroad are introduced. The researches and application progress of mineral

Manganese BeneficiationProcessing Technology in China

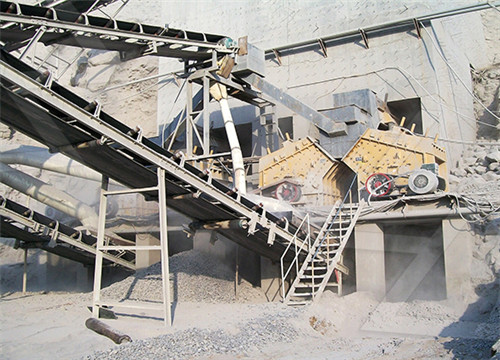

2022年5月27日 At present, the process flow of manganese oxide ore treatment in China is generally to crush the ore to 6 ~ 0mm or 10 ~ 0mm, and then group it, jigging for coarse

Manganese Mining and Processing for

2023年3月9日 The importance of Manganese exploded with the development of modern steelmaking technology in the 1860s. As an alloy, it decreases the brittleness of steel and imparts strength. The main

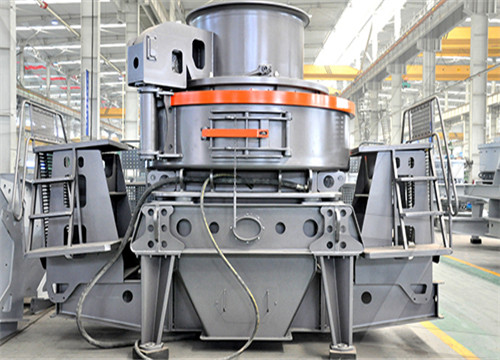

Manganese Ore Processing Plant and Equipment

2020年3月6日 The process of processing manganese oxide ore is generally crushing the ore to 6-0mm or 10-0mm, and then classifying, coarse grade particles are sent to jig

Manganese ore processing technology and

2019年7月2日 The technological process of dealing with manganese oxide ore is generally crushing the ore to 6 ~ 0 mm or 10 ~ 0 mm, then classification, jigging at the coarse level and shaking at the fine level.

Manganese Ore Processing Mineral Processing

2016年4月27日 The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores

Manganese processing Britannica

manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an

An Overview of Manganese Recovery by Hydro and Pyro

2016年6月17日 The challenge is to develop a technology providing an acceptable rate of manganese ore reduction at low temperature. Also, a technologically important factor is the concentration of CO in the gas phase. Kononov et al. have worked on carbothermal reduction of manganese ore in hydrogen, results are illustrated through Fig. 1. Very few

Hydrometallurgical Processing of Manganese Ores: A

2017年6月25日 The production of manganese alloy from manganese ore is an energy intensive process and therefore, apart from manganese ore, power plays an important role in the production of ese alloy. There are basically two mangan processes for the manufacturing of the alloy using either one of high, medium or low grade ore, viz; Blast fur-nace and

A Review of Low Grade Manganese Ore Upgradation

2019年7月29日 The low- and high-Al manganese ore fines were compared, and the results suggest that the high-Al manganese ore fines (1.70 wt% Al2O3) obtained sinters with higher strength with lower fuel consumption.

Novel Process of Reduction Roasting Manganese Ore

The reaction process could be described by an unreacted nuclear model. Manganese was extracted by sulfuric acid solution after reduction by sulfur waste. In sulfuric acid, 95.2 wt% Mn extraction was achieved, using a roasting temperature of 450 °C, roasting time of 30 min, and S 2 /MnO 2 molar ratio of 0.40.

Hydrometallurgical Processing of Manganese Ores: A Review

2015年6月12日 Hydrometallurgy is the most suitable extractive technique for the extraction and purification of manganese as compared to all other techniques including biometallurgy and pyrometallurgical processes. In the hydrometallurgical processing of manganese from its ore, the leach liquors often contain divalent ions such as iron, manganese, copper,

Top 5 Manganese Mining CompaniesManganese

2022年7月13日 The largest manganese mining companies that have some exposure to manganese incorporate: . Assmang. Assmang is one of the manganese mining companies that was founded in 1935 and is based in Johannesburg, South Africa.It is involved in the extraction of manganese ore, iron ore, and chrome ores. The vast bulk of the company’s

Elcora Receives Manganese Production License in Morocco

2023年3月9日 Manganese ore 37% sells at about $331USD / metric ton (https: “The extraction and processing of Manganese requires specialized skills and technology, and the development of Manganese-based batteries has the potential to create new industries driving Elcora’s growth”.

中国科学院过程工程研究所机构知识库(CAS OpenIR): A

2022年11月15日 In this study, a sustainable low-temperature roasting and water leaching process for simultaneously extracting Mn, Cu, Co, and Ni from ocean manganese nodules was proposed. The results show that the primary mineral phase of iron-manganese oxides in the ocean manganese nodules reacted with ammonium sulfate during the roasting

Stock Market FinancialContent Business Page

1 After years of development, the technology of producing electrolytic manganese metal with manganese carbonate ore in China has formed a relatively mature production process. First, manganese carbonate ore grinding mill equipment is used to grind manganese carbonate ore, and then liquid preparation, leaching, purification, electrolysis

Manganese processing The metal and its alloys Britannica

Manganese ore is reduced and then leached with sulfuric acid. The solution is purified, and manganous dioxide is obtained by electrolysis. It can also be obtained by the oxidation of manganese compounds of lower valance or by the thermal decomposition of manganese nitrate. Potassium permanganate (KMnO 4) finds wide use as an oxidizing agent. It

An Overview of Manganese Recovery by Hydro and Pyro

2016年6月17日 The challenge is to develop a technology providing an acceptable rate of manganese ore reduction at low temperature. Also, a technologically important factor is the concentration of CO in the gas phase. Kononov et al. have worked on carbothermal reduction of manganese ore in hydrogen, results are illustrated through Fig. 1. Very few

Novel Process of Reduction Roasting Manganese Ore

The reaction process could be described by an unreacted nuclear model. Manganese was extracted by sulfuric acid solution after reduction by sulfur waste. In sulfuric acid, 95.2 wt% Mn extraction was achieved, using a roasting temperature of 450 °C, roasting time of 30 min, and S 2 /MnO 2 molar ratio of 0.40.

Advances in mineral processing technologies related to

Li T. Technology of low grade pyrolusite ore reduction process and recent advances. China’s Manganese Industry 2008; 26: 4–13. Search in Google Scholar. Li Y, Zhu T. Recovery of low grade haematite via fluidised bed magnetising roasting: investigation of magnetic properties and liberation characteristics.

Hydrometallurgical Processing of Manganese Ores: A Review

2015年6月12日 Hydrometallurgy is the most suitable extractive technique for the extraction and purification of manganese as compared to all other techniques including biometallurgy and pyrometallurgical processes. In the hydrometallurgical processing of manganese from its ore, the leach liquors often contain divalent ions such as iron, manganese, copper,

Manganese BeneficiationProcessing Technology in China

2022年5月27日 At present, the process flow of manganese oxide ore treatment in China is generally to crush the ore to 6 ~ 0mm or 10 ~ 0mm, and then group it, jigging for coarse grade and shaking tables for a fine grade. The equipment is mostly Hartz reciprocating jig and 6-s shaking table. jig separator. shaking table.

Manganese Ore Processing Plant and Equipment

2020年3月6日 The process of processing manganese oxide ore is generally crushing the ore to 6-0mm or 10-0mm, and then classifying, coarse grade particles are sent to jig sorting, and fine grade particles are sent to shaker for sorting. 3. Strong Magnetic Separation Method. Manganese mineral is a weak magnetic mineral (specific magnetic susceptibility

Elcora Receives Manganese Production License in Morocco

2023年3月9日 Manganese ore 37% sells at about $331USD / metric ton (https: “The extraction and processing of Manganese requires specialized skills and technology, and the development of Manganese-based batteries has the potential to create new industries driving Elcora’s growth”.

Stock Market FinancialContent Business Page

1 After years of development, the technology of producing electrolytic manganese metal with manganese carbonate ore in China has formed a relatively mature production process. First, manganese carbonate ore grinding mill equipment is used to grind manganese carbonate ore, and then liquid preparation, leaching, purification, electrolysis