Calcite Paint Pin Type Industrial Horizontal Grinding Mill

CalciteCalcite Industrial Grinding Mill SHANGHAI

2021年8月6日 Calcite Industrial Ultrafine Powder Grinding Mill. Powder Surface Modification machine. Calcite Grinding Mill. Calcite Powder Production Line. Calcite

China Calcite Grinding Manufacturers and Factory,

Calcite Grinding Manufacturers, Factory, Suppliers From China, We are anticipating to cooperate with you around the basis of mutual added benefits and common

Grinding mills for mining and minerals processing

Metso Outotec has over 100 years of experience in horizontal grinding mills and has always been an industry-leader in innovative technology. Metso Outotec's unmatched expertise

calcite grinding mill

2023年2月17日 calcite grinding mill. Calcite is a mineral with a Mohs hardness of 3, which makes it a relatively soft mineral. It is a widely used industrial mineral and is used in a

Products https://calcitegrindingmill/

2022年9月27日 Calcite Industrial Ultrafine Powder Grinding Mill. Calcite industrial ultrafine powder grinding mill is a high efficient grinding mill that can grind calcite into fine powder.

Identifying a Pin Mill for Optimal Performance

2018年3月21日 A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. and

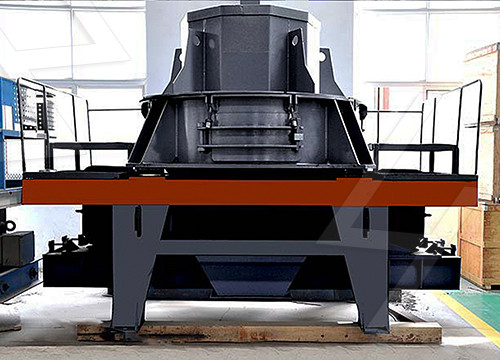

What are the types of industrial grinding mills? mpl

2021年7月7日 pumice. bentonite. sepiolite. Industrial grinding mills generally include vertical roller mills, ultra-fine grinding mills, high-pressure suspension roller mills,

Grinding Mills Common Types Mineral

2016年11月7日 For the grinding of the largest quantities of material however, the ball, tube or rod mill is used almost exclusively, since these are the only types of mill which possess throughput capacity of the required

Sand Mill In Paint Industry Painting

2022年5月18日 The horizontal or vertical sand mills are used as standard in the paint industry for pigment dispersion. Root is manufacturer of horizontal sand mill bead mill

use of calcite in paint industry Grinding Mill China

Calcite Mineral Uses and Properties GEOLOGY.COM. The construction industry is the primary consumer of calcite in Modern construction uses calcite in the Some of the

Grinding of Calcite in a Stirred Media Mill Using the Box

2020年3月14日 The grinding experiments were performed by a Union Process STD-01 batch-type laboratory scale pin-type vertical stirred mill with a 750 cc ceramic (Al2O3) tank (see Figure2). The stirrer axis was fitted with a shaft and four arms. The shaft length was 26.6 cm, the length of each mixing arm was

China Pin Mill, Pin Mill Manufacturers, Suppliers, Price

30L Big Capacity Ultrafine Rod Pin Horizontal Sand Mill for Grinding Water-Based Printing Ink/Phthalocyanine Blue/Pearl Powder/Copper Chrome Basket Mill Bead Mill Pin Type Ceramic Grinding Mill for Paints Coating Ink . US$ 2800-6800 / Piece (FOB Price) Fiber Herb Plants Stainless Steel Industrial Pin Mill Pulverizer . US$ 3910-8920

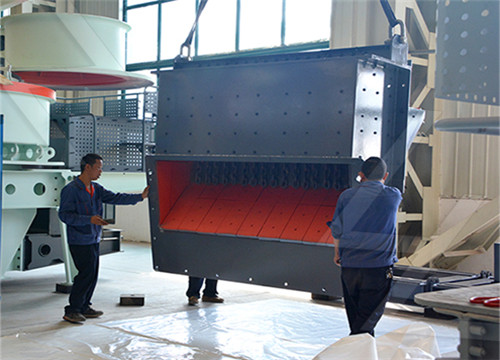

Industrial Pin Mill Turbo Mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products . Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc. The average achievable particle size range of the pin mill is

Grinding mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products. Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc. The average achievable particle size range of the pin mill is around a d50 of

Identifying a Pin Mill for Optimal Performance

2018年3月21日 A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness. The mill can accept feed materials with a particle size ranging from 20 microns to 0.5 in. and

Mixer Suppliers, Manufacturers Cost Price Powder Mixing

2023年3月6日 Basket Mill For Paint Making. ELE bead mill is suitable for nano grinding, specially for pin type and turbo type, high energy and. Add to Inquiry ESW-750 Lab Scale Horizontal Bead Mill. Suitable for continuous or circulating processing. Easy to operate, using smaller grinding chamber,

Pin Mill Stainless Steel Yinda

Using pin mills offers a ton of benefits and advantages. As a matter of fact you’ll love them because of their overall flexibility and versatility. You can use pin mills for a wide range of industrial applications whatever industry you are in. Some of its notable benefits and advantages include, but are not limited to:

Mill, Grinding mill All industrial manufacturers

roller mill. horizontal miscellaneous waste stainless steel. Rotational speed: 348, 360, 428, 270 rpm. Motor power: 1 kW. Machine length: 610, 660, 762, 927, 1,676 mm. non-stainless steel external surfaces coated with a white two-part epoxy paint • Safety trip switch across the top of the mill AVAILABLE OPTIONS: • Stainless steel type

ColorDye Grinding Paint Mills Thomasnet

Pompano Beach, FL Manufacturer*, Distributor $1 4.9 Mil 1936 10-49. Manufacturerdistributor of lab roller paint, colordye grinding mills. Lab roller mills can be used with any standard size cans for blending dry powders. Features include continuous duty 1/75 hp fan-cooled motorscord for 115 V. Brands.

Pin Milling Baking Processes BAKERpedia

Pin milling is a size-reduction technology often used as an auxiliary grinding mechanism in mills and analytical laboratories. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. 1. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal kernels in a

The Influence of Stirred Mill Orientation on Calcite Grinding

2021年4月21日 The purpose of this study was to investigate the dry grindability of calcite powders in a vertically and horizontally orientable laboratory batch type stirred mill. The experimental results were evaluated using stress intensity analysis. The performance was also compared in terms of mill orientation. The results showed that the d50 values

Industrial Pin Mill Turbo Mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products . Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc. The average achievable particle size range of the pin mill is

Grinding mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered products. Common applications involve the fine grinding of sugar, salt, sodium bicarb, etc. The average achievable particle size range of the pin mill is around a d50 of

HOSOKAWAMICRON CORPORATION

HOSOKAWA / MICRON Hammer Mill H, Hammer Breaker HB The Hammer Mill is widely used for coarse/medium grinding of minerals, stuffs, fertilizers, and chemicals. Raw materials as big as a few tens of mm are ground to an average particle size of roughly 0.5-2mm by the impact generated from the swing hammers traveling at circumferential

Pin Mills Size Reduction Equipment for Bulk

Pin Mills. 1-315-797-0090. sales@munsonmachinery. In addition to a removable outer disc, the inner rotating disc of this pharmaceutical-grade model CIM-18-S316 is also removable, providing full access to both

Paint, InksCoating Zirpro

1 Saint-Gobain ZirPro has been supplying high-quality ceramic media to the paint, ink and coating industries for more than 40 years. This experience enables ZirPro to offer a market-leading range of media: ER120, Rimax®, Zirmil® Ce, Zirmil® Y and Zirmil® TZP, which are designed to meet the exacting demands of specific suspension types.

(PDF) Interaction Between TiO2 and Calcite

2012年9月24日 In the present , a new type of pigment mixture for possible use in architectural water based paints was developed through grinding. The effect of different types of grinding methods on

Pin Mill Classifier Milling Systems Inc.

The Pin Mill from CMAS is an excellent grinding mill option when your production targets call for particle sizes at medium fineness. Learn more today! Request Quote. CMS Global +1-905-456-6700. Search Menu.

Grinding Mills and Their Types IspatGuru

2015年4月9日 Grinding mills are size reductions machines that often follow crushers in the processes where finer products are desired after crushing. Different grinding machines are usually named as mills, for example rod

Pin Milling Baking Processes BAKERpedia

Pin milling is a size-reduction technology often used as an auxiliary grinding mechanism in mills and analytical laboratories. Pin mills use metal disks fitted with pins to efficiently and quickly break up materials. 1. Compared to roller mills, pin mills offer the milling industry a means for reducing the size of cereal kernels in a