How Concrete Aggregate Is Produced

Concrete Production an overview ScienceDirect Topics

Concrete production is a highly intensive energy-consuming process and presently facing a number of challenges in reducing the carbon footprint and making it more economic.

进一步探索

Process of manufacture of concrete SlideShareConcrete production produces eight percent of the world's ca根据热度为您推荐•反馈

Aggregates Cement

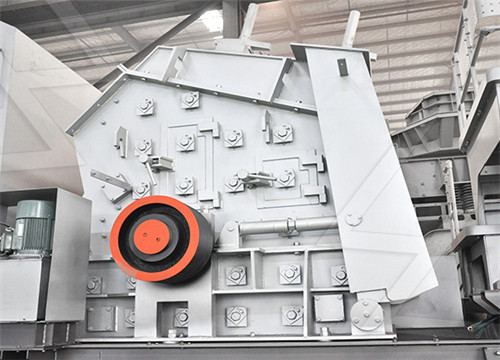

Crushed aggregate is produced by crushing quarry rock, boulders, cobbles, or large-size gravel. Recycled concrete is a viable source of aggregate and has been satisfactorily

进一步探索

Types of aggregate used in building construction Civil SirTypes of Aggregates Used in Construction DAILY CIVIL根据热度为您推荐•反馈

Concrete Aggregate an overview ScienceDirect Topics

Ian Sims, Bev Brown, in Lea's Chemistry of Cement and Concrete (Fourth Edition), 1998. Design of processing plants. The objective of any concrete aggregate processing

How Is Concrete Made? Learn What Goes Into Concrete

2022年2月4日 Normal strength concrete. This concrete mixture is made of cement, aggregates, and water and has a mixing proportion of 1:2:4 (one part cement, two parts

Recycled Concrete Aggregate- How to Make It and What

2023年2月15日 The produced coarse recycled concrete aggregate is sent to a rotary kiln for calcination, which can burn the combustible impurities into ashes. The calcined

How Is Concrete Produced? Concrete Information

How is concrete produced? Concrete production is the process of mixing the different ingredients—water, aggregate, cement, and any additives. Modern concrete typically

How concrete is made material, manufacture, making,

A modern kiln can produce as much as 6,200 tons of clinker a day. 2 The clinker is then cooled and ground to a fine powder in a tube or ball mill. The mixing operation uses

What Is Concrete Made of and How Is It Made? Engineer

2021年3月30日 The proportion of water and cement. The chemical reaction of cement with water brings out cement’s amazing qualities. As we discussed, the combination of water

How Is Recycled Concrete Aggregate Made?

2021年7月12日 Recycled concrete aggregate is also known as “crushed concrete”. This name paints a plain picture of what RCA is: crushed asphalt and concrete debris that has been screened, cleaned, and reused in

Concrete Production an overview ScienceDirect Topics

Concrete production is a highly intensive energy-consuming process and presently facing a number of challenges in reducing the carbon footprint and making it more economic. Sustainable technologies in maintaining concrete structures are proving to be a great challenge. Microbially induced carbonate precipitation (MICP) has developed as a novel

Aggregates for Concrete American Concrete Institute

2017年8月5日 Hydraulic cement concrete is a cement and water paste in which aggregate particles are embedded. Aggregate is granular material such as sand, gravel, crushed stone, blast-furnace slag, and lightweight aggregates that usually occupies approxi-mately 60 to 75% of the volume of concrete. Aggregate properties significantly affect the workability of

What Are Aggregates and How Are They Used? CEMEX

Using aggregate materials for concrete reduces production costs and increases the resistance of concrete mixes. Crushed aggregates make up for around 60% to 75% of the volume of concrete. Gravel deposits are produced by a natural process of moisture and erosion. There are different types of gravel ¾ '' and 1 ½ '', seal, hydraulic base

How is Concrete Made What is Concrete CivilJungle

2023年2月14日 Concrete is widely used building material all over the world in the Construction Industry. Concrete is defined as the uniform mixture of cement, fine aggregate, coarse aggregate and water in the appropriate proportion which will set hardened and acquire the strength after a particular period. Concrete is a composite material which is

Materials Free Full-Text Recycled Concrete Aggregate

This stone reports an evaluation of the properties of medium-quality concrete incorporating recycled coarse aggregate (RCA). Concrete specimens were prepared with various percentages of the RCA (25%, 50%, 75%, and 100%). The workability, mechanical properties, and durability in terms of abrasion of cured concrete were examined at

Mesoscale discrete analysis of mechanical properties of

The application of recycled coarse aggregate (RA) to produce recycled aggregate concrete (RAC) requires the investigation of its mechanical properties. From literature review, it is found that the experimental data scatters in large extent and even contradictory results exist. Therefore, numerical tool is an appropriate option to evaluate the

Application of Solid Wastes in Concrete Production– A

2023年3月8日 Concrete is the backbone of infrastructural developments and most widely used construction material of every country. It mainly consists of cement, fine aggregate, coarse aggregate, and water

Could turning waste into aggregate save farmland from

21 小时之 Aggregate pits cover 5,900 football fields worth of land in Waterloo region. Mark Reusser, vice president of the Ontario Federation of Agriculture, would like to see more done to preserve farmland

Turning the water off on aggregate washing with RCAS

2023年3月9日 Kayasand sees a future where quarries can turn the water off on aggregate washing by replacing their water-based washing systems with much cleaner and more precise dry washing systems, such as found in the RCAS system.. When Japanese company Kemco first launched their innovative V7 sand manufacturing technology 20

Performance of portland/silica fume cement concrete

This stone shows how the use of recycled aggregate in the concrete industry has a great potential in reducing the demand for natural aggregate and the amount of solid waste dumped at landfill sites. The main objective of this stone is to design a concrete made with different proportions of coarse recycled concrete aggregate (RCA) having a similar 28

Materials Free Full-Text Recycled Concrete Aggregate

This stone reports an evaluation of the properties of medium-quality concrete incorporating recycled coarse aggregate (RCA). Concrete specimens were prepared with various percentages of the RCA (25%, 50%, 75%, and 100%). The workability, mechanical properties, and durability in terms of abrasion of cured concrete were examined at

Using Recycled Aggregate from Demolished Concrete to

2022年9月28日 5.1 Experiments of Lightweight Concrete Produced by Natural Aggregate. First mixture: the aggregate size was between 8 and 25 mm and the cement to aggregate ratio was 1/6.W/C = 0.45 and cement calibre was 340 kg/m 3.. Compression resistance was up to 147.6 kg/cm 2 after 28 days and the density was 1963 kg/m 3, and this density was

Mesoscale discrete analysis of mechanical properties of

The application of recycled coarse aggregate (RA) to produce recycled aggregate concrete (RAC) requires the investigation of its mechanical properties. From literature review, it is found that the experimental data scatters in large extent and even contradictory results exist. Therefore, numerical tool is an appropriate option to evaluate the

Using Recycled Concrete as Aggregate Civil Engineering

2020年8月13日 What is Recycled Concrete Aggregate. Recycled concrete as aggregate is nothing but aggregates produced from the previously used construction material such as masonry or concrete. Recycled aggregates consist of hard, graduated fragments of inert materials, which include sand, crushed stone, rock dust, gravel, slag or powder.

Application of Solid Wastes in Concrete Production– A

2023年3月8日 Concrete is the backbone of infrastructural developments and most widely used construction material of every country. It mainly consists of cement, fine aggregate, coarse aggregate, and water

Performance of portland/silica fume cement concrete

This stone shows how the use of recycled aggregate in the concrete industry has a great potential in reducing the demand for natural aggregate and the amount of solid waste dumped at landfill sites. The main objective of this stone is to design a concrete made with different proportions of coarse recycled concrete aggregate (RCA) having a similar 28

Could turning waste into aggregate save farmland from

21 小时之 Aggregate pits cover 5,900 football fields worth of land in Waterloo region. Mark Reusser, vice president of the Ontario Federation of Agriculture, would like to see more done to preserve farmland

Turning the water off on aggregate washing with RCAS

2023年3月9日 Kayasand sees a future where quarries can turn the water off on aggregate washing by replacing their water-based washing systems with much cleaner and more precise dry washing systems, such as found in the RCAS system.. When Japanese company Kemco first launched their innovative V7 sand manufacturing technology 20

A Guide to Aggregate and its Supply and delivery Medium

2016年10月17日 10–20 mm Aggregate. 10–20 mm: For laying out and filling of the concrete roads, the granite sand of the size 10–20 mm is perfect. They are also used for the sub base preparation of the road

2016 aggregate production statistics : PitQuarry

2017年5月29日 In 2016, 1.48 billion tons of crushed stone valued at more than $16.2 billion was produced by 1,430 companies operating 3,700 quarries, 82 underground mines, and 187 sales and distribution yards in 50 states. Leading states were, in descending order of production, Texas, Pennsylvania, Florida, Missouri, Ohio, North Carolina, Georgia,