Application Of Roll Crushing Equipment In Copper

Roll Crusher an overview ScienceDirect Topics

Roll crushers apply shear or compression to the material that is going to be reduced in size. This action occurs between two hardened surfaces. The speed and diameter of the rolls,

Factors to Consider When Selecting the Proper Roll Crusher

2019年11月21日When selecting the proper Roll Crusher for an application, you must fully consider all the components of the crushing process. There are numerous factors to be considered, such as: Material

(PDF) Review of the in-pit crushing and conveying (IPCC

2011年10月24日Typical Twin Roll Crusher Or Sizer . Island copper: in-pit crusher and conveyor system under construction. Island Miner,

High Pressure Grinding Roll for advanced crushing

We designed and built our express frame for a faster and safer replacement of the roll surfaces. With the minerals processing industry trending towards larger equipment, we specifically developed the express frame to

Laboratory Roll Crusher 911Metallurgist

The 911MPELRC Laboratory Roll Crushers are typically applied in laboratory or pilot plant applications after primary reduction of the infeed material. Roll crushers operate with a minimum of dust generation and

High Pressure Grinding Rolls 911Metallurgist

2020年7月28日High-pressure grinding rolls were first applied in the minerals industry in 1985 in cement plants. The main objective for the use of HPGR was the significant energy savings achievable. Today, they are

Copper Ore Processing Solution Eastman Rock Crusher

Copper ore processing and production processes mainly include three processes: crushing, grinding, and beneficiation. In the crushing process, three-stage closed-circuit crushing is a modern method suitable for high

Copper Scrap Metal Reduction Equipment

Contact Us For questions or other information about copper processing equipment. 1319 Macklind Ave, St. Louis, MO 63110 Ph: 314‑781‑6100 Fax: 314‑781‑9209

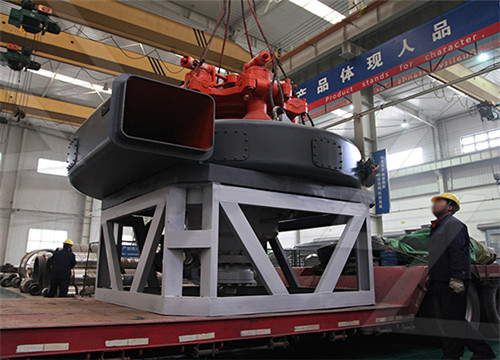

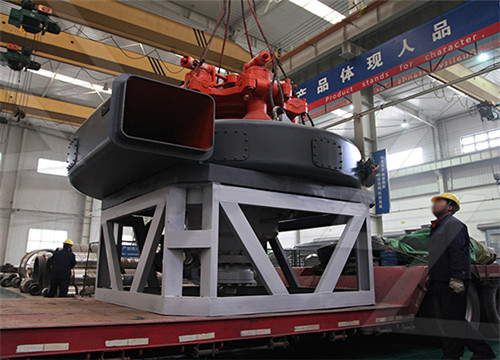

Primary Crusher an overview ScienceDirect Topics

Gyratory and Cone Crusher. In Mineral Processing Design and Operations (Second Edition), 2016. Abstract. Detail descriptions of designs are given of large gyratory

Roll Crushers McLanahan

How Roll Crushers Work Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll.

Roll Crusher an overview ScienceDirect Topics

Roll crushers apply shear or compression to the material that is going to be reduced in size. This action occurs between two hardened surfaces. The speed and diameter of the rolls, the desired capacity, and the feed and product size distribution are all critical in the proper sizing and operation of this type of machine.

Factors to Consider When Selecting the Proper Roll

2019年11月21日When selecting the proper Roll Crusher for an application, you must fully consider all the components of the crushing process. There are numerous factors to be considered, such as: Material

Effect of Copper and Chromium Addition on the Mechanical and

2021年12月2日In brickyard industry, smooth roll crusher is the most critical component in the brick production process. The main damage to the surface of the roll crusher comes from abrasion wear. Grey cast iron with a CE around 4.0 was chosen for the manufacture of these rolls crushers. Castings with various compositions in the basic Class 25 grey cast

High Pressure Grinding Rolls 911Metallurgist

2020年7月28日High-pressure grinding rolls were first applied in the minerals industry in 1985 in cement plants. The main objective for the use of HPGR was the significant energy savings achievable. Today, they are

11.25 Clay Processing US EPA

crushers, smooth roll crushers, toothed roll crushers, and hammer mills are used for secondary crushing, which further reduces particle size to 3 mm (0.1 in.) or less. For some applications, tertiary size reduction is necessary and is accomplished by means of ball, rod, or pebble mills, which are often combined with air separators.

Uses of Different Types of Crusher linkedin

2023年3月10日The material is fed into the crushing chamber from the top and is crushed between the mantle and the concaves. The crushed material is then discharged through the bottom of the crusher. Roll Crushers:

CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

– Serrated or toothed roll crusher Smooth roll crusher • Two heavy smooth faced roll rotating towards each other at same speed on parallel horizontal axes • Size of the material caught by the rolls depends upon the coefficient of friction between the material and the roll surface • Dp = 0.04R + g Dp maximum size of particle . R

CRUSHER NEW Samshin Co., Ltd

Roll crusher is one of the most widely used grinders in many industries, such as coal, salt, clay, bauxite, limestone and mining. It is designed as a secondary grinder of brittle minerals. It is mainly used in the treatment of wet sticky feeds. Single roll crusher are used to grind frozen or agglomerated materials. Advantages

Ore grinding Application and Roller Crusher Type lab double

Quality Ore grinding Application and Roller Crusher Type lab double toothed roll crusher find quality laboratory test equipment, Crusherlaboratory test equipment from Mineral Equipment Manufacturing Co., Ltd of China Suppliers .

Roll Crusher HRC

For industrial beneficiation of primary and secondary raw materials, selection of the most appropriate crushing method plays a key role in the production of specific grain sizes, shapes and surfaces, or to break down multi-component materials. The selected crusher must conform to today’s stringent requirements for processing rocks, ores and

(PDF) Review of the in-pit crushing and conveying (IPCC

2011年10月24日Typical Twin Roll Crusher Or Sizer . Island copper: in-pit crusher and conveyor system under construction. Island Miner, Vol. 11, No. 1, pp. 1-2. W., 2009, The application of mobile in-pit

Laboratory Roll Crusher 911Metallurgist

The 911MPELRC Laboratory Roll Crushers are typically applied in laboratory or pilot plant applications after primary reduction of the infeed material. Roll crushers operate with a minimum of dust generation and produce a material with a tight size envelope containing a minimum of fines.

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

Advantage. 1.The rollers is wear-resisting chromium molybdenum copper alloy with long service. 2.The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly. 3.This crusher is equipped with motorless scraper.

Factors to Consider When Selecting the Proper Roll

2019年11月21日When selecting the proper Roll Crusher for an application, you must fully consider all the components of the crushing process. There are numerous factors to be considered, such as: Material

Roll Crusher HRC

For industrial beneficiation of primary and secondary raw materials, selection of the most appropriate crushing method plays a key role in the production of specific grain sizes, shapes and surfaces, or to break down multi-component materials. The selected crusher must conform to today’s stringent requirements for processing rocks, ores and

Effect of Copper and Chromium Addition on the Mechanical and

2021年12月2日In brickyard industry, smooth roll crusher is the most critical component in the brick production process. The main damage to the surface of the roll crusher comes from abrasion wear. Grey cast iron with a CE around 4.0 was chosen for the manufacture of these rolls crushers. Castings with various compositions in the basic Class 25 grey cast

HPGR High Pressure Grinding Rolls Mineral

2016年7月13日In hard-rock metals mining applications, HPGRs are currently in use in tertiary and quaternary crushing applications, as well as in secondary pebble crushing. In many respects, HPGRs replace

11.25 Clay Processing US EPA

crushers, smooth roll crushers, toothed roll crushers, and hammer mills are used for secondary crushing, which further reduces particle size to 3 mm (0.1 in.) or less. For some applications, tertiary size reduction is necessary and is accomplished by means of ball, rod, or pebble mills, which are often combined with air separators.

Size Reduction Equipment: Types, Applications, Construction,

Capable of being utilized on a wider range of objects, impactors are usually utilized for crushing non-abrasive, soft objects like gypsum, phosphate, soft metallic cores, seeds, and coal. However, they may also be utilized to crush abrasive, hard objects like gravel, basalt, asphalt, and concrete.

Copper Beneficiation Process, Equipment Mineral Processing

This setup is a complete set rock copper processing plant, including crushing, grinding, grading, sieving, separation, drying and other processes. Below is copper mining equipment: 1. Crushinggrinding: The chute feeder is for feeding raw material to primary jaw crusher more stable and smoothly.

Uses of Different Types of Crusher linkedin

2023年3月10日The material is fed into the crushing chamber from the top and is crushed between the mantle and the concaves. The crushed material is then discharged through the bottom of the crusher. Roll Crushers:

CHAPTER 20: SIZE REDUCTION EQUIPMENT FOR SIZE

– Serrated or toothed roll crusher Smooth roll crusher • Two heavy smooth faced roll rotating towards each other at same speed on parallel horizontal axes • Size of the material caught by the rolls depends upon the coefficient of friction between the material and the roll surface • Dp = 0.04R + g Dp maximum size of particle . R

Ore grinding Application and Roller Crusher Type lab double

Quality Ore grinding Application and Roller Crusher Type lab double toothed roll crusher find quality laboratory test equipment, Crusherlaboratory test equipment from Mineral Equipment Manufacturing Co., Ltd of China Suppliers .

Laboratory Roll Crusher 911Metallurgist

The 911MPELRC Laboratory Roll Crushers are typically applied in laboratory or pilot plant applications after primary reduction of the infeed material. Roll crushers operate with a minimum of dust generation and

(PDF) Review of the in-pit crushing and conveying (IPCC

2011年10月24日Typical Twin Roll Crusher Or Sizer . Island copper: in-pit crusher and conveyor system under construction. Island Miner, Vol. 11, No. 1, pp. 1-2. W., 2009, The application of mobile in-pit

Mining Iron Ore Rollers Crushing Machine Price, Coal Double

Advantage. 1.The rollers is wear-resisting chromium molybdenum copper alloy with long service. 2.The gap between the rollers is adjustable, so that the output size and capacity will be changed accordingly. 3.This crusher is equipped with motorless scraper.

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日These types of Roll Crushers produce a cubical product with minimal fines generation, and can handle higher capacities. In the correct application, Triple and Quad Roll Crushers are capable of performing both primary and secondary stages of material reduction in one machine.