Coal Mining Modern Website Fine Iron Ore And Beneficiation

FINEX® — ENVIRONMENTALLY SAFE IRONMAKING

In the Finex process, fine iron ore is directly charged at the top of a cascade of fluidized-bed reactors, where it is heated and reduced to direct-reduced iron (DRI) by means of a reduction gas derived from the

Mining ArcelorMittal

World-class operation. We have a geographically diversified portfolio of mining operations in Brazil, Bosnia, Canada, Kazakhstan, Liberia, Mexico and Ukraine that in 2020 produced

进一步探索

ArcelorMittal Our minesProduction facilities ArcelorMittal根据热度为您推荐•反馈

Beneficiation Anglo American South Africa

Beneficiation is a driver for empowerment of HDSAs and enables the development of new entrepreneurs in downstream and sidestream industries. In pursuing economically

Coal Beneficiation Process Diagram Mineral Processing

The Problem with Coarse and Fine Coal BeneficiationThe Problem with Coal Recovery and Cleaning by FlotationCoal Flotation ProblemsCoal Beneficiation Process

Market SpecificationsAsh and sulphur content is desired to be as low as, or lower than, for regular lump coal. Generally, for anthracite, not over 13 per cent ash is desired. Bituminous coal operations usually limit ash to not more than 8 per cent in the fines.Production ProblemsFlotation or gravity concentration are generally applied only to washery fines that otherwise would not be saleable and which generally have to be impounded to prevent stream pollution. Because of the low price secured, the expense of treatment must be held to a minimum. Pyrite and coars在911metallurgist上查看更多信息预计阅读时间:13 分钟

Iron Ore Beneficiation Multotec

Overview of a typical Iron Ore Process flow sheet: Primary stages of iron ore beneficiation, essentially, result in three iron ore product types, namely Coarse,

Beneficiation of Iron Ore Mineral ProcessingMetallurgy

2016年5月24日Beneficiation of Iron Ore treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice. This also applies to iron ores of the non-magnetic type which after a

Iron Ore Beneficiation Mineral Processing

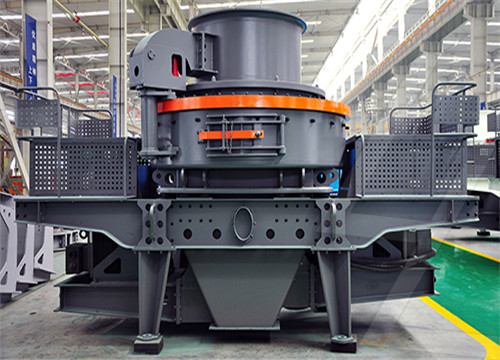

The iron ore beneficiation process mainly includes crushing, screening, grinding (ball mill), classification (classifier), separation (gravity separation, flotation, magnetic separation),

Coal Processing Multotec

Coal Processing. Coal processing uses physical, mechanical and/or chemical methods, to remove rocks, dirt, ash, sulphur, and other contaminants and unwanted materials to produce high-quality coal for

Technical Resource Document: Extraction and

Table 1-3. Ore Treated to Product Ratios and Material Handled to Product Ratios for U.S. Surface Iron Ore Mines, in Thousand Long Tons, 1988 .. 1-13 Table 1-4.

Dry beneficiation of fine coal using density ScienceDirect

2016年7月1日Dry beneficiation of fine coal of +150–500 μm in size was conducted using density-segregation in a gas–solid fluidized bed without any separation media.The coal particles in a cylindrical column (inner diameter = 100 mm and bed height = 100 mm) were fluidized at a given air velocity u 0 /u mf = 1.3–3.0 for thirty minutes where u 0 and u mf

FINEX® — ENVIRONMENTALLY SAFE IRONMAKING

In the Finex process, fine iron ore is directly charged at the top of a cascade of fluidized-bed reactors, where it is heated and reduced to direct-reduced iron (DRI) by means of a reduction gas derived from the

Iron ore quality a potential headwind to green steelmaking IEEFA

2022年6月28日The global steel sector is still largely focused on existing coal-consuming blast furnace operations, giving iron ore miners an incentive to continue producing blast furnace-grade iron ore, rather than ores with higher iron

Recent developments in beneficiation of fine and ultra-fine coal

2020年7月1日Request PDF Recent developments in beneficiation of fine and ultra-fine coal -review stone Generation of fines and ultra-fines is a concept that mining and metallurgical sectors can never shy

Deep Learning Approach at the Edge to Detect Iron Ore Type

There is a constant risk of iron ore collapsing during its transfer between processing stages in beneficiation plants. Existing instrumentation is not only expensive but also complex and challenging to maintain. In this research, we propose using edge artificial intelligence for early detection of landslide risk based on images of iron ore transported on conveyor belts.

Coal Beneficiation Multotec

Coal Beneficiation products: Multotec is a world-leader in cyclones and spiral concentrators! This classification equipment is central to coal beneficiation. Dense medium cyclones: cast in 27% high-chrome cast iron or manufactured from steel with ceramic linings provides maximum wear resistance in harsh coal beneficiation conditions.

Beneficiation of Fine Iron Ores using the Desand Process AusIMM

The low-grade clay-rich -1.0 mm fraction of fine iron ores have often proved difficult to upgrade and capital intensive to process when using traditional wet beneficiation technology including single or two stage hydrocyclone desliming, wet high intensity magnetic separation (WHIMS), spirals and final dewatering using fine screens. Very fine (<0.010

Iron Ore Processing, General SpringerLink

2022年10月20日Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and shipping to steel mills. Iron ore processing is characterized by a constant adaptation to changing raw materials and market conditions.

TECHNOLOGIES F0R FINE COAL BENEFICIATION IN INDIA

INDIAN SCENARIO OF COKING COAL PLANTS 9Prior to 1950, there were no Beneficiation plants, since selective mining was in practice. 9The first Indian coal washery was set up at West Bokaro in 1951, followed by the second one installed at Jamadoba in 1952 both by M/s Tata Iron and Steel Limited.

sbmchina/sbm stone coal hydraulic beneficiation process.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

2023 Wet Magnetic ore washing, beneficiation and purification

2023 Wet Magnetic Ore Washing,Beneficiation And Purification,Desliming And Concentration Permanent Drum Magnetic Separator,Find Complete Details about 2023 Wet Magnetic Ore Washing,Beneficiation And Purification,Desliming And Concentration Permanent Drum Magnetic Separator,Magnetic Separator Separator Magnet Magnetic

Dry Iron Ore Beneficiation ST EquipmentTechnology

Iron ore extraction is mainly performed through open pit mining operations, resulting in significant tailings generation. The iron ore production system usually involves three stages: mining, processing and pelletizing activities. Of these, processing ensures that an adequate iron grade and chemistry is achieved prior to the pelletizing stage.

Enhanced Gravity Concentrators Prospects in Fine Coal

the established process of froth flotation in fine coal beneficiation. 2. Amongst the enhanced gravity concentrators, Kelsey jig appears to be the most promising in fine coal beneficiation as the mode of particle separation inside this unit is continuous and the capacity of each unit is much higher than the other units. 3.

Recent advances in the beneficiation of ultrafine coal particles

2018年9月1日Flotation cleaning is one of the most effective ways to achieve the beneficiation/upgrading of fine coal particles (normally <0.5 mm, especially for <0.2 mm) in industry (Wang et al. 2018; Wang

Iron ore quality a potential headwind to green steelmaking IEEFA

2022年6月28日The global steel sector is still largely focused on existing coal-consuming blast furnace operations, giving iron ore miners an incentive to continue producing blast furnace-grade iron ore, rather than ores with higher iron

Award-winning Optima Classifier supplied for fine coal beneficiation

2022年6月5日AddThis Utility Frame. R/€ = 19.3396. Au 1825.41 $/oz. Home / Sector News / Environmental / RecyclingWaste Management ← Back.

Dry beneficiation of fine coal using density ScienceDirect

2016年7月1日Dry beneficiation of fine coal of +150–500 μm in size was conducted using density-segregation in a gas–solid fluidized bed without any separation media.The coal particles in a cylindrical column (inner diameter = 100 mm and bed height = 100 mm) were fluidized at a given air velocity u 0 /u mf = 1.3–3.0 for thirty minutes where u 0 and u mf

Recent developments in beneficiation of fine and ultra-fine coal

2020年7月1日Request PDF Recent developments in beneficiation of fine and ultra-fine coal -review stone Generation of fines and ultra-fines is a concept that mining and metallurgical sectors can never shy

Deep Learning Approach at the Edge to Detect Iron Ore Type

There is a constant risk of iron ore collapsing during its transfer between processing stages in beneficiation plants. Existing instrumentation is not only expensive but also complex and challenging to maintain. In this research, we propose using edge artificial intelligence for early detection of landslide risk based on images of iron ore transported on conveyor belts.

Coal Beneficiation Multotec

We supply coal beneficiation equipment for the entire process, from R.O.M stockpile to dewatering. As experts in the field with over 40 years’ experience, our team of metallurgists will assist you in optimising your coal benficiation plant. Remove contaminants and lower-grade coal from the coal stream

Beneficiation of Fine Iron Ores using the Desand Process AusIMM

The low-grade clay-rich -1.0 mm fraction of fine iron ores have often proved difficult to upgrade and capital intensive to process when using traditional wet beneficiation technology including single or two stage hydrocyclone desliming, wet high intensity magnetic separation (WHIMS), spirals and final dewatering using fine screens. Very fine (<0.010

TECHNOLOGIES F0R FINE COAL BENEFICIATION IN INDIA

INDIAN SCENARIO OF COKING COAL PLANTS 9Prior to 1950, there were no Beneficiation plants, since selective mining was in practice. 9The first Indian coal washery was set up at West Bokaro in 1951, followed by the second one installed at Jamadoba in 1952 both by M/s Tata Iron and Steel Limited.

sbmchina/sbm stone coal hydraulic beneficiation process.md at

Contribute to sbmcrushers/sbmchina development by creating an account on GitHub.

2023 Wet Magnetic ore washing, beneficiation and purification

2023 Wet Magnetic Ore Washing,Beneficiation And Purification,Desliming And Concentration Permanent Drum Magnetic Separator,Find Complete Details about 2023 Wet Magnetic Ore Washing,Beneficiation And Purification,Desliming And Concentration Permanent Drum Magnetic Separator,Magnetic Separator Separator Magnet Magnetic

Dry Iron Ore Beneficiation ST Equipment

Iron ore extraction is mainly performed through open pit mining operations, resulting in significant tailings generation. The iron ore production system usually involves three stages: mining, processing and pelletizing

Recent advances in the beneficiation of ultrafine coal particles

2018年9月1日Flotation cleaning is one of the most effective ways to achieve the beneficiation/upgrading of fine coal particles (normally <0.5 mm, especially for <0.2 mm) in industry (Wang et al. 2018; Wang

Enhanced Gravity Concentrators Prospects in Fine Coal

the established process of froth flotation in fine coal beneficiation. 2. Amongst the enhanced gravity concentrators, Kelsey jig appears to be the most promising in fine coal beneficiation as the mode of particle separation inside this unit is continuous and the capacity of each unit is much higher than the other units. 3.

Minerals Free Full-Text Native Bacteria Isolated from Phosphate

2023年3月10日Mining and processing phosphate ore are among the essential branches of the economy in some developing countries, including Algeria. Conventional ore beneficiation methods can harm the environment by consuming tremendous amounts of water resources (during washing and flotation), potentially hazardous chemicals, and