Drawing Of Moving Jaw Plate For Impact Crusher

AMIT 135: Lesson 5 Crushing Mining Mill Operator

Jaw Crusher. Crushing occurs between two moving plates that are arranged to form an acute angle to apply a compressive force that

Jaw Crusher Liner Plate DesignProfile Shapes

根据热度为您推荐•反馈

(PDF) Design of Impact stone crusher machine

2019年5月31日Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher.

Jaw Crusher Plate > Crusher Parts > Products >

We know that the jaw crusher spare parts maily include the fixed jaw plate and the movable jaw plate.'s Jaw crusher plates are manufactured with super high

A REVIEW ON STUDY OF JAW CRUSHER Metallurgist

jaw plates wear on a macroscopic level will be helpful to the jaw crusher design for better performance. Since the slide between the particles and the jaw plates is replace by the

Jaw Crusher VS Impact Crusher JXSC Machine

2020年2月28日The moving jaw plate leaves the fixed jaw plate under the action of the pull rod and spring, and the broken material is discharged from the lower mouth of the crushing chamber. With the continuous

Jaw Plate Casteel Foundry

Toogle Plate,Toogle Bearing ,Toggle block Jaw Wedge, Kawasaki Jaw Crusher Plate 2021-06-25 Janpanese Jaw Crusher Parts: Item Names: Jaw Plate s ,Stationary Jaw

Jaw Plate Toughing Crusher

Additional information. Introduction:Jaw plate is the main wear part of jaw crusher, which is divided into moving jaw plate and fixed jaw plate TOUGHING’s jaw plate and cheek

Manganese Casting Jaw Crusher Wear Parts Fixed / Swing /

Manganese Casting Jaw Crusher Wear Parts Fixed / Swing / Moving Jaw Plate, Find Details and Price about Jaw Crusher Plate Fixed Jaw Plate from Manganese Casting

Jaw Crusher MOVING JAW PLATE

drawing of moving jaw plate for jaw crusher. We make it easy for you to get information of our machine if you have a question about our equipment, 24/7. Swing Jaw Plate For

Size Reduction Visual Encyclopedia of Chemical Engineering

Jaw Crushers. Jaw crushers consist of a rectangular frame with a fixed jaw plate and a jaw stock carrying the moving jaw. The moving jaw swings toward the fixed jaw in the forward stroke, the material is crushed, and discharge takes place during the backward or freeing stroke. The jaw crusher pictured below can be used to crush items from large

(PDF) Design of Impact stone crusher machine

2019年5月31日Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact stone crusher....

Design and Construction of Rock Crushing Machine from

Cheek plates The positioning of these plates on the jaw crusher justifies the name “Cheek Plates”. They are made or coated with high strength manganese steel for durability purpose. As it can be seen in the assembly drawing, the design is done in such a way as to act as additional lock to key down the fixed jaw to its stock. Figure 5

Crushing in Mineral Processing

2015年12月26日The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS CSS. OSS and CSS will define a

A REVIEW ON STUDY OF JAW CRUSHER Metallurgist

jaw plates wear on a macroscopic level will be helpful to the jaw crusher design for better performance. Since the slide between the particles and the jaw plates is replace by the vertical movement distance of the moving jaw plate in this , the further study is needed to predict the accurate wear rate.

EXPERIMENTAL EFFECT ON JAW CRUSHER PLATE IJARIIE

moving jaw plate is different in wear. The stationary plate is more wear than moving plate. The different wear rate for stationary jaw plate and moving jaw plate is based on work hardening effect during running-in period and to the different wear micromechanism acting on the jaw surfaces. Keyword: Jaw crusher, Impact, Abrasive wear

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

of the movable jaw, which is controlled by toggle plate and drawback rod. Figure 2 shows the components of a single toggle jaw crusher. Figure 1a: Blake Crusher Figure 1b: Dodge Crusher Figure 1c: Universal Jaw Crusher Figure 2: Cross-section of single series jaw crusher [11] Figure 1a: Blake crusher Pivot

Jaw Crusher VS Impact Crusher JXSC Machine

2020年2月28日The moving jaw plate leaves the fixed jaw plate under the action of the pull rod and spring, and the broken material is discharged from the lower mouth of the crushing chamber. With the continuous

Manganese Casting Jaw Crusher Wear Parts Fixed / Swing / Moving Jaw Plate

Manganese Casting Jaw Crusher Wear Parts Fixed / Swing / Moving Jaw Plate, Find Details and Price about Jaw Crusher Plate Fixed Jaw Plate from Manganese Casting Jaw Crusher Wear Parts Fixed / Swing / Moving Jaw Plate

(PDF) Optimum design and analysis of (the) swinging

2010年4月30日The design of swing jaw plate is carried out by using CAD i.e., jaw plate has been solid modeled by using CATIAV5R16. FEA is applied to assembled structure of swinging jaw plate and lever to

What Is a Jaw Crusher and What Can It Do for You?

2021年1月10日The composition of a jaw crusher is characterized by its two jaw plates, one fixed and the other moving, both oriented to create a V-shaped chamber through which materials fall and become repeatedly crushed. These crusher jaw plates are most often corrugated in appearance but can also be smooth.

How does a Single Toggle Jaw Crusher work? RUBBLE MASTER

This geometry turns the rotary motion of the eccentric shaft into a fore aft motion at the bottom of the jaw plate creating the crushing action. The material is then compressed between the two jaw plates, reducing in size as it gets lower in the crushing chamber until it extits at the bottom. The output size of the material can be varied by

Jaw Crusher ScienceDirect

2016年1月1日Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of the plates are made of hardened steel. fraction K 2 that was crushed and fragmented in the crusher while a fraction K 1 remained unbroken and passed through the crusher without drawing extra power.

Size Reduction Visual Encyclopedia of Chemical Engineering

Jaw Crushers. Jaw crushers consist of a rectangular frame with a fixed jaw plate and a jaw stock carrying the moving jaw. The moving jaw swings toward the fixed jaw in the forward stroke, the material is crushed, and discharge takes place during the backward or freeing stroke. The jaw crusher pictured below can be used to crush items from large

Design and Construction of Rock Crushing Machine from

Cheek plates The positioning of these plates on the jaw crusher justifies the name “Cheek Plates”. They are made or coated with high strength manganese steel for durability purpose. As it can be seen in the assembly drawing, the design is done in such a way as to act as additional lock to key down the fixed jaw to its stock. Figure 5

(PDF) Optimum design and analysis of (the) swinging

2010年4月30日The design of swing jaw plate is carried out by using CAD i.e., jaw plate has been solid modeled by using CATIAV5R16. FEA is applied to assembled structure of swinging jaw plate and lever to

Plate of Jaw Crusher

further study of swing jaw plate with stiffener is done using finite element analysis. 4) The design and modeling jaw plates of crusher is accomplished by using CAD i.e. parametric design package (CATIAP3V5R15). 5) Comparison of the results obtained through Finite Element Analysis of jaw plates by using ALGOR V19 programming (Trail Version).

A REVIEW ON STUDY OF JAW CRUSHER Metallurgist

jaw plates wear on a macroscopic level will be helpful to the jaw crusher design for better performance. Since the slide between the particles and the jaw plates is replace by the vertical movement distance of the moving jaw plate in this , the further study is needed to predict the accurate wear rate.

Crushing in Mineral Processing

2015年12月26日The Crusher throw is defined as the distance in the direction of compression the moving crushing surfaces/plates travel from OSS to CSS. Throw = OSS CSS. OSS and CSS will define a

EXPERIMENTAL EFFECT ON JAW CRUSHER PLATE IJARIIE

moving jaw plate is different in wear. The stationary plate is more wear than moving plate. The different wear rate for stationary jaw plate and moving jaw plate is based on work hardening effect during running-in period and to the different wear micromechanism acting on the jaw surfaces. Keyword: Jaw crusher, Impact, Abrasive wear

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE

of the movable jaw, which is controlled by toggle plate and drawback rod. Figure 2 shows the components of a single toggle jaw crusher. Figure 1a: Blake Crusher Figure 1b: Dodge Crusher Figure 1c: Universal Jaw Crusher Figure 2: Cross-section of single series jaw crusher [11] Figure 1a: Blake crusher Pivot

What Is a Jaw Crusher and What Can It Do for You?

2021年1月10日The composition of a jaw crusher is characterized by its two jaw plates, one fixed and the other moving, both oriented to create a V-shaped chamber through which materials fall and become repeatedly crushed. These crusher jaw plates are most often corrugated in appearance but can also be smooth.

Manganese Casting Jaw Crusher Wear Parts Fixed / Swing / Moving Jaw Plate

Manganese Casting Jaw Crusher Wear Parts Fixed / Swing / Moving Jaw Plate, Find Details and Price about Jaw Crusher Plate Fixed Jaw Plate from Manganese Casting Jaw Crusher Wear Parts Fixed / Swing / Moving Jaw Plate

How does a Single Toggle Jaw Crusher work?

This geometry turns the rotary motion of the eccentric shaft into a fore aft motion at the bottom of the jaw plate creating the crushing action. The material is then compressed between the two jaw plates, reducing in

Pioneer® Jaw Crushers Astec

The Pioneer ® Series of jaw crushers represents the very latest in jaw crusher technology.. Engineered to be the highest-capacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers. Pair that with heavy-duty flywheels for reduced horsepower requirements and

Crusher Jaw Plates For Popular Brands By Hunan JY Casting

Normally, there are 13 steps to change new jaw crusher plates: Prepare to work tools:600 live-mouth wrench, wire rope, hand hammer, mast, sledgehammer, electric welding, crane Prepare new jaw plate Stop the feeding and the operation of the crusher, pay attention to wearing insulated gloves to prevent wet hands and electric shock.

Know-how RUBBLE MASTER

The main wear parts of the jaw crusher are its fixed jaw, moving jaw and cheek plates which can be changed easily and quickly. In contrast to impact crushers, jaw crusher wear parts have a comparatively long service life but jaw crushers cannot achieve the same reduction ratio on material.

- 泸州二手碎石机

- 大型采石场机器

- Grinding Stones Assorted

- 花岗岩侧石生产厂家

- 武汉的建筑垃圾清运

- Flowchart Of Copper Floating Equipment

- Kefid Primary Cone Mining Mill Manuals

- 选矿效率

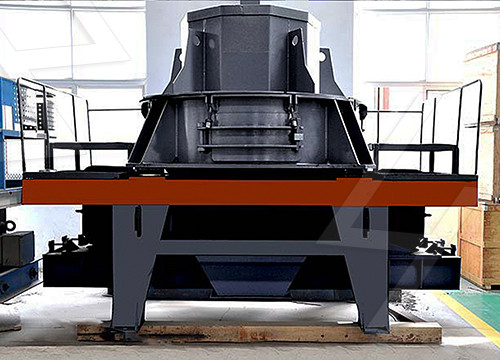

- Procedure Of Cone And Vsi Metance Of Mining Mill

- 矿山碎石除尘泡沫

- Growth Of Stone Mining Mill Industry In Pathankot

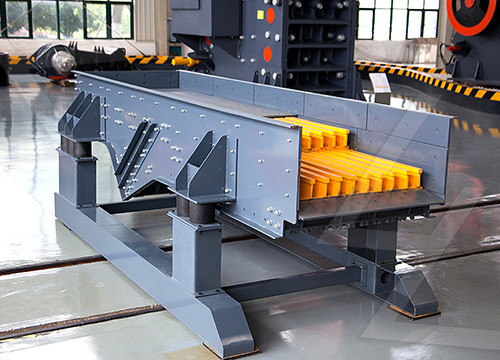

- 移动震动筛分设备

- 二手选煤设备

- 最新矿山挖掘机驾驶员招聘

- Impact Crusher Manufacturer In Saudi Arabia